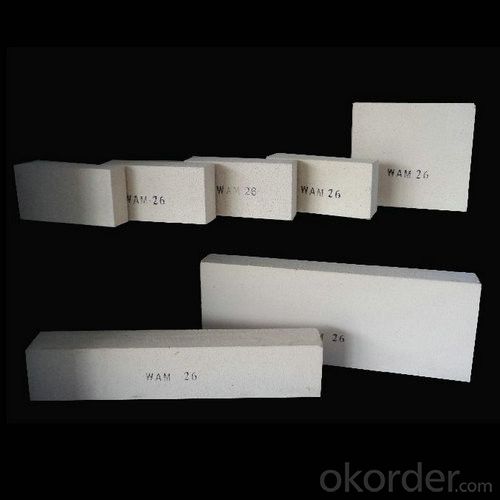

Insulating Fire Brick (IFB) in GJM 23, 26, 30 Brands

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Insulating Firebricks

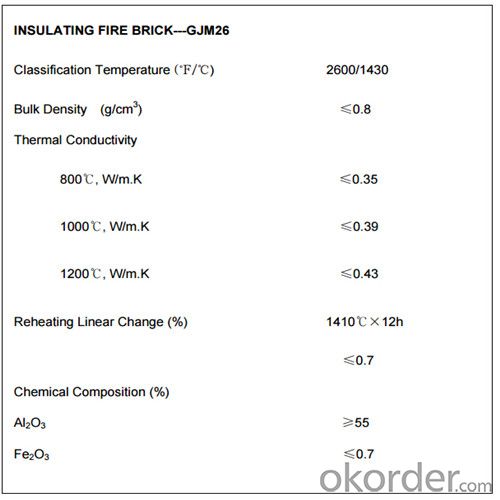

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Image of Insulating Firebricks

Technical Data of Insulating Firebricks

Feature of Insulating Firebricks

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application of Insulating Firebricks

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: Are insulating fire bricks resistant to carbon monoxide attack?

- Insulating fire bricks have a general resistance to carbon monoxide attack. They are made from materials that can withstand high temperatures and chemical corrosion, including carbon monoxide. These bricks are commonly used in environments where high temperatures and exposure to gases like carbon monoxide are frequent, such as furnaces, kilns, and fireplaces. The composition of the bricks allows them to endure long periods of exposure to carbon monoxide without deteriorating or reacting with the gas. However, it is important to remember that continuous exposure to extremely high levels of carbon monoxide can eventually harm any material, including insulating fire bricks. Therefore, it is still crucial to ensure proper ventilation and safety precautions when dealing with carbon monoxide in any situation.

- Q: Are insulating fire bricks suitable for insulation in heat treatment furnaces?

- Insulation in heat treatment furnaces can be effectively achieved by using insulating fire bricks. These bricks have been specifically engineered to endure high temperatures while offering exceptional thermal insulation. Their low thermal conductivity aids in reducing heat loss and ensuring a consistent temperature within the furnace. Furthermore, insulating fire bricks are lightweight, facilitating easier handling and installation. Moreover, they exhibit considerable resistance to thermal shock, enabling them to withstand sudden temperature variations without sustaining any cracks or fractures. To sum up, opting for insulating fire bricks proves to be a trustworthy and efficient solution for heat treatment furnace insulation.

- Q: Can insulating fire bricks be used in pottery kilns?

- Yes, insulating fire bricks can be used in pottery kilns. Insulating fire bricks, also known as refractory bricks, are specifically designed to withstand high temperatures and provide insulation to retain heat in kilns. These bricks are made from materials such as alumina, silica, and other refractory materials, which have excellent thermal resistance properties. Using insulating fire bricks in pottery kilns helps to maintain a consistent temperature, reduce heat loss, and ensure efficient firing of clay and glazes. Additionally, these bricks help to prolong the lifespan of the kiln by protecting the interior walls from extreme temperatures. Therefore, insulating fire bricks are an ideal choice for pottery kilns and are widely used in the pottery industry.

- Q: Are insulating fire bricks resistant to spalling?

- Yes, insulating fire bricks are resistant to spalling.

- Q: What is the cost of insulating fire bricks?

- The cost of insulating fire bricks can vary depending on various factors such as the quantity needed, the quality of the bricks, and the supplier. On average, insulating fire bricks can range from $2 to $5 per brick. However, the price can go higher for specialty bricks or those with specific features such as higher insulation ratings or increased durability. It is always recommended to obtain quotes from multiple suppliers to compare prices and ensure the best value for money.

- Q: How do insulating fire bricks affect overall heating and cooling costs?

- Insulating fire bricks can significantly reduce overall heating and cooling costs. These bricks have high insulation properties that minimize heat transfer, resulting in better temperature control and less energy loss. By creating a barrier against heat flow, insulating fire bricks help to maintain desired temperatures more efficiently, reducing the need for excessive heating or cooling. This ultimately leads to lower energy consumption and cost savings for both heating and cooling systems.

- Q: Are insulating fire bricks resistant to chlorine gas?

- Generally, insulating fire bricks possess resistance to chlorine gas. These bricks are composed of refractory materials that are formulated to endure high temperatures and combat chemical corrosion. As chlorine gas is highly reactive, it has the potential to corrode or harm various materials. However, insulating fire bricks exhibit a strong resistance to chemical attack, thereby making them appropriate for situations where exposure to chlorine gas is likely. It should be noted that the composition and quality of these bricks may differ, hence it is advisable to consult the manufacturer or supplier for precise details regarding their resistance to chlorine gas.

- Q: Are insulating fire bricks resistant to gas permeability?

- Yes, insulating fire bricks are resistant to gas permeability. These bricks are designed to have low porosity and high density, which helps to prevent the penetration of gases through their structure. They are made from high-quality refractory materials, such as clay or silica, and are manufactured using a special process to ensure minimal pore size and tight packing. This makes them highly effective in containing gases and preventing their leakage. Insulating fire bricks are commonly used in various high-temperature applications, including furnaces, kilns, and industrial boilers, where gas tightness is essential for efficient and safe operations.

- Q: What is the average density of insulating fire bricks?

- The specific composition and manufacturing process of insulating fire bricks can cause the average density to vary. Generally, insulating fire bricks possess a lower density than regular bricks. The average density of insulating fire bricks typically falls between 0.6 grams per cubic centimeter (g/cm³) and 1.5 g/cm³. This reduced density is accomplished by incorporating lightweight materials or incorporating air pockets during manufacturing. The lower density of insulating fire bricks enables them to offer exceptional thermal insulation properties, rendering them well-suited for applications that require containment of high temperatures while minimizing heat loss.

- Q: Are insulating fire bricks suitable for use in heat exchangers?

- Yes, insulating fire bricks are suitable for use in heat exchangers. These bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for heat transfer processes. They are commonly used in various industries, including metallurgy, glass, and ceramic manufacturing, where heat exchangers are essential for efficient heat transfer.

Send your message to us

Insulating Fire Brick (IFB) in GJM 23, 26, 30 Brands

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords