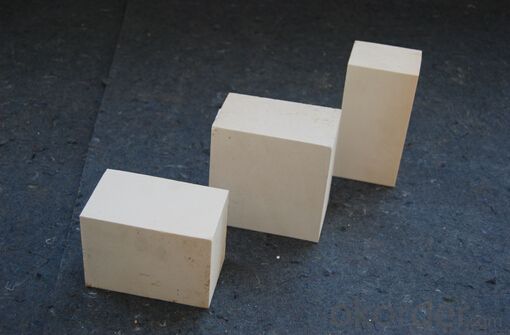

Insulating Fire Brick - Refractory Mullite Jm 28

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Top insulation ceramic fiber blanket

General information of ceramic fiber blanket

Cmax ceramic fiber blanket is made of high quality kaolin clay, centrifugal high purity alumina and silica or blowing process. It's no asbestos. Double side acupuncture for easy installation provides a lot of tension or strength of the blanket.

Products are divided into standard, high pressure, HA and Hz, respectively, corresponding to the highest service temperature of 1000, 1100, 1200, and 1350

Characteristics of ceramic fiber blanket

Heat resistance

Light weight

Low thermal conductivity

Low heat storage

Thermal shock toughness

High tensile strength

Application of ceramic fiber blanket

Refractory fiber lining for petrochemical process heating furnace

Heat treatment furnace or intermittent (shuttle) kiln heat surface lining

General oven standby insulation

Heat sealing or kiln kiln car door

Electrical insulation

Ceramic fiber blanket

Common problem solutions

1. What products do you have?

We have all kinds of refractory bricks, refractory casting materials, mortar, cement, ceramic fiber products, etc..

Or you can browse our products to choose what you need.

2. How to control product quality?

With strict quality control system throughout the material selection and production process, we have the quality of refractory materials and ceramic fiber products to meet customer requirements.

From the selection of raw materials, the quality of our control to start. The quality certificate of the raw material is required, each batch of the products are to be tested in the use of the forward line. In the production process, the quality control by the workers, and then each piece of classification, and through the quality supervision and inspection.

3. Can you give me a brief introduction to the application of your product?

My company is mainly engaged in refractories in the steel, cement, glass, ceramics, petrochemical, electric power and other industries.

4. What information do you need if I need you?

In order to select the right products, we will provide us with information, such as the United States, technical data, order quantity, product application, etc..

If you have any questions, please contact us.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. How do you control the products quality?

With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervise.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q: Can insulating fire bricks be cut to custom sizes?

- Yes, insulating fire bricks can be cut to custom sizes. Insulating fire bricks are typically made from lightweight materials such as ceramic fibers or lightweight aggregates, which make them relatively easy to cut. They can be cut using various tools such as a saw, knife, or specialized cutting equipment. It is important to take proper safety precautions and use appropriate tools and techniques to ensure a clean and accurate cut. Additionally, it is advisable to consult the manufacturer's guidelines or seek professional advice to ensure that the cutting process does not compromise the integrity or thermal properties of the insulating fire bricks.

- Q: How do insulating fire bricks affect the overall thermal stability of a structure?

- The overall thermal stability of a structure is greatly enhanced by insulating fire bricks. These bricks are designed to have low thermal conductivity, which effectively minimizes heat transfer between different parts of the structure. The use of insulating fire bricks significantly reduces the amount of heat that can escape or enter a structure, resulting in improved thermal stability. In cold weather, these bricks prevent heat from escaping, keeping the interior warm and reducing the need for excessive heating. Conversely, in hot weather, they prevent the entry of external heat, helping to keep the interior cool and reducing the need for excessive cooling. The low thermal conductivity of insulating fire bricks also helps maintain a consistent temperature within the structure. This is especially important in areas with significant temperature fluctuations, as it regulates the internal climate and enhances comfort for occupants. Furthermore, insulating fire bricks are highly resistant to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. By providing a stable and durable barrier against extreme temperatures, these bricks contribute to the overall thermal stability of a structure, ensuring its longevity and reliability. In conclusion, insulating fire bricks positively impact the thermal stability of a structure by minimizing heat transfer, maintaining consistent temperatures, and withstanding thermal shock. Their use greatly enhances the comfort, energy efficiency, and durability of a building.

- Q: Do insulating fire bricks have a high resistance to spalling?

- Insulating fire bricks possess a remarkable ability to resist spalling. Spalling occurs when the surface of a material breaks or flakes off, and fire bricks are particularly susceptible to this phenomenon due to exposure to intense heat and thermal shock. However, insulating fire bricks are specially engineered to endure these extreme temperatures and thermal cycling, resulting in a significant resistance to spalling. These bricks are crafted from top-notch refractory materials like alumina or silica, renowned for their exceptional thermal shock resistance. Furthermore, they are manufactured with low thermal conductivity, effectively reducing heat transfer and minimizing the chances of spalling. In summary, insulating fire bricks are the perfect choice for applications demanding high spalling resistance, such as furnaces, kilns, and other environments with elevated temperatures.

- Q: Can insulating fire bricks be used in the construction of glass melting tanks?

- Yes, insulating fire bricks can be used in the construction of glass melting tanks. These bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for applications such as glass melting tanks where maintaining consistent and controlled heat is crucial.

- Q: Can insulating fire bricks be used in the construction of autoclaves?

- Insulating fire bricks are indeed applicable for the construction of autoclaves. Autoclaves necessitate materials capable of enduring high temperatures and pressures, and insulating fire bricks are specifically engineered to exhibit exceptional thermal resistance and insulation characteristics. These bricks consist of refractory materials such as alumina, silica, and other additives that enable them to withstand extreme temperatures and thermal shocks. Furthermore, they possess a lightweight composition and low thermal conductivity, thereby reducing heat loss and enhancing energy efficiency within autoclaves. Moreover, insulating fire bricks are endowed with a commendable load-bearing capacity, rendering them suitable for the structural elements of autoclaves. In summary, the utilization of insulating fire bricks during the construction of autoclaves serves to guarantee the safety and effectiveness of the equipment.

- Q: Are insulating fire bricks resistant to thermal expansion or contraction?

- Yes, insulating fire bricks are resistant to thermal expansion and contraction. These bricks are made of materials that have low thermal conductivity, allowing them to withstand high temperatures without undergoing significant expansion or contraction. This property makes them ideal for applications where thermal stability and insulation are required, such as in kilns, furnaces, and other high-temperature environments.

- Q: What are the sizes of lightweight thermal insulation bricks?

- Low iron mullite, high aluminum light insulating refractory brick, diatomite insulating refractory brick. Sizes can be customized for ordinary profiled sizes

- Q: Can insulating fire bricks be used in combination with other insulation materials?

- Yes, insulating fire bricks can be used in combination with other insulation materials. They can be used as a primary insulation layer or in conjunction with other materials such as ceramic fiber insulation or refractory coatings to enhance insulation efficiency and achieve higher temperature resistance. This combination of insulation materials can provide better thermal insulation properties and increased energy efficiency in various applications such as furnaces, kilns, and high-temperature industrial processes.

- Q: What bricks are thermal insulation bricks?

- First, replace the aluminum plate, honeycomb board, curtain wall and other common decorative materials, multi-functional integration, a construction can solve the two requirements of thermal insulation decoration, smooth, smooth and beautiful, decorative strong.Two, high strength, good rigidity, light quality, seismic resistance, wind resistance, creep resistance, superior performance, reduce building load, more economical and durable.Three, fire retardant, heat preservation, energy saving, sound insulation, heat insulation, crack resistance, waterproof, according to the 65% building energy conservation requirements for construction design.Four. The installation of the finished product is simple, the process is simplified, the construction period is shortened, and the quality is easy to control.Five, no aluminum, steel, keel support, embedded in the installation, reduce the insulation board and the gap between the wall. Increased safety system.Six, no radiation, green environmental protection, can be widely used in various types of public buildings and family interior decoration.

- Q: Can insulating fire bricks be used for kiln furniture?

- Yes, insulating fire bricks can be used for kiln furniture. Insulating fire bricks are lightweight, have high insulating properties, and can withstand high temperatures, making them suitable for use as shelves, posts, or supports in kilns. They help to conserve energy, improve heat distribution, and protect the kiln structure.

Send your message to us

Insulating Fire Brick - Refractory Mullite Jm 28

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords