Insulating Fire Brick - Insulation Brick, Insulating Brick, GJM23, GJM26, GJM28, GJM30, GJM32

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Insulating Fire Brick GJM23

Insulating fire bricks GJM23 are made from high purity alumina and low iron content raw materials. The insulating fire bricks are produced by mixing, casting or extruding, drying, sintering and grinding. Our insulating fire bricks GJM23 temperature is 1260℃(2300℉). A variety of type could be done according to customer’s request.

To make our firebricks more energy and cost effective, we have different manufacturing methods for our insulating fire bricks casting and extruding method.

For insulating fire bricks GJM23,we choose the casting methord.The casting insulating fire bricks offering the lowest density, the lowest thermal conductivity for the application above 1000℃.

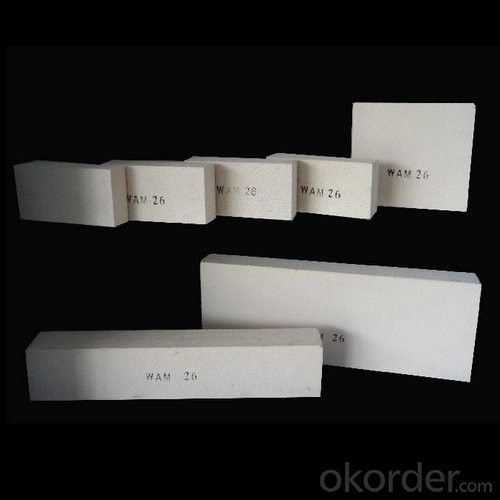

General Information of Insulating Fire Brick GJM26

Insulating fire brick GJM26 are produced by mixing, casting or extruding, drying, sintering and grinding. Our insulating fire bricks GJM23 temperature is 1430℃(2600℉). We could supply a wide range of shapes.

To make our firebricks more energy and cost effective, we have different manufacturing methods for our insulating fire bricks casting and extruding method.

For insulating fire bricks GJM26,we choose the extruding method. Extruding insulating fire bricks have better strength and offering great performance in load bearing applications and in conditions where abrasion from mechanical abuse or flow of hot gases.

General Information of Insulating Fire Brick GJM28

Insulating fire brick GJM28 are produced by high purity alumina and low iron raw materials. A viariety of shapes are available.

To make our firebricks more energy and cost effective, we have different manufacturing methods for our insulating fire bricks casting and extruding method.

For insulating fire bricks GJM28,we choose the extruding method. Extruding insulating fire bricks have better strength and offering great performance in load bearing applications and in conditions where abrasion from mechanical abuse or flow of hot gases.

General Information of Insulating Fire Brick GJM30

Insulating fire brick GJM30 are produced by mixing, casting or extruding, drying, sintering and grinding. Our insulating fire bricks GJM30 temperature is 1430℃(2600℉). We could supply a wide range of shapes.

To make our firebricks more energy and cost effective, we have different manufacturing methods for our insulating fire bricks casting and extruding method.

For insulating fire bricks GJM30,we choose the extruding method. Extruding insulating fire bricks have better strength and offering great performance in load bearing applications and in conditions where abrasion from mechanical abuse or flow of hot gases.

Typical Application of Insulating Fire Brick

Typical applications of magnesia bricks include ferroalloy furnace, metal mixer, Non-metallurgy industry furnace, high temperature kiln, calcined lime furnace, regenerator in glass furnace.

Technical Data of Insulating Fire Brick

| JM23 | JM26 | JM28 | JM30 | JM32 | ||||

| Physical Properties: | ||||||||

| Classifiction Temperature | ℃ | 1260.0 | 1430.0 | 1500.0 | 1600.0 | 1650 | ||

| Density | Kg/m3 | 550.0 | 850.0 | 900.0 | 1000.0 | 1100 | ||

| Cold Crushing Strength | Mpa | 1.2 | 2.0 | 2.5 | 2.8 | 3.5 | ||

| Reheating Linear Change(24hrs) | ||||||||

| 1230℃ | % | 0.4 | ||||||

| 1300℃ | ||||||||

| 1400℃ | % | 0.5 | ||||||

| 1510℃ | % | 0.6 | ||||||

| 1600℃ | % | 0.7 | ||||||

| 1650℃ | % | 0.8 | ||||||

| Hot Load Strength Deform(90 minutes) | ||||||||

| 1100℃ at 0.034 Mpa(5psi) | % | 0.1 | ||||||

| 1260℃ at 0.069 Mpa(10psi) | % | 0.2 | ||||||

| 1320℃ at 0.069 Mpa(10psi) | % | 0.3 | ||||||

| 1370℃ at 0.069 Mpa(10psi) | % | 0.2 | 0.1 | |||||

| Thermal Conductivity | ||||||||

| 400℃ | W/m.k | 0.2 | 0.3 | 0.3 | 0.3 | 0.32 | ||

| 600℃ | W/m.k | 0.2 | 0.3 | 0.3 | 0.3 | 0.35 | ||

| 800℃ | W/m.k | 0.2 | 0.3 | 0.4 | 0.4 | 0.38 | ||

| 1000℃ | W/m.k | 0.2 | 0.3 | 0.4 | 0.4 | 0.42 | ||

| 1200℃ | W/m.k | 0.4 | 0.4 | 0.4 | 0.44 | |||

| 1400℃ | W/m.k | |||||||

| Specific Heat | KJ/Kg.K | 1.1 | 1.1 | 1.1 | 1.1 | 1.10 | ||

| Chemical Analysis: | ||||||||

| Al2O3 | % | 47.0 | 50.0 | 60.0 | 70.0 | 75.0 | ||

| SiO2 | % | 44.4 | 47.1 | 38.2 | 28.3 | 23.2 | ||

| Fe2O3 | % | 0.9 | 0.7 | 0.6 | 0.5 | 0.5 | ||

| TiO2 | % | 1.2 | 0.1 | 0.1 | 0.1 | 0.1 | ||

| CaO | % | 5.2 | 0.1 | 0.1 | 0.1 | 0.1 | ||

| MgO | % | 0.3 | 0.2 | 0.1 | 0.1 | 0.1 | ||

| Na2O+K2O | % | 1.1 | 1.7 | 0.8 | 0.7 | 0.6 | ||

Photo of Insulating Fire Brick

- Q: How shall the sintered porous self insulation bricks be laid at the bottom of the beam?

- And the concrete beam should be broken brick masonry. Top packing.

- Q: Are insulating fire bricks suitable for use in thermal shock applications?

- Yes, insulating fire bricks are suitable for use in thermal shock applications. Insulating fire bricks are designed to withstand rapid changes in temperature without cracking or breaking, making them ideal for thermal shock environments where there are frequent and extreme temperature fluctuations.

- Q: Is it possible to paint or coat insulating fire bricks?

- Indeed, it is feasible to apply paint or coat insulating fire bricks. Nevertheless, it is imperative to utilize a type of paint or coating that can endure elevated temperatures, given that insulating fire bricks are intended for usage in exceedingly hot surroundings. Ordinary paint or coatings may not be appropriate since they can combust or deteriorate under high temperatures. It is advisable to employ specialized high temperature paint or coatings that have been specifically formulated to withstand the intense heat of insulating fire bricks. Typically, these types of paint or coatings possess a resistance to high temperatures of several hundred degrees Celsius or greater. Moreover, it is crucial to adequately clean and prepare the surface of the bricks prior to applying any paint or coating to ensure optimal adhesion and durability.

- Q: Can insulating fire bricks be used in high-temperature filters?

- Yes, insulating fire bricks can be used in high-temperature filters. These bricks are designed to withstand extreme temperatures and provide excellent insulation. They can effectively trap and filter out impurities in high-temperature environments, making them suitable for use in high-temperature filters.

- Q: Can insulating fire bricks be used in rocket stoves?

- Yes, insulating fire bricks can be used in rocket stoves. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, which makes them ideal for use in rocket stoves. They help to retain heat efficiently, ensuring better combustion and increased fuel efficiency in rocket stoves.

- Q: Can insulating fire bricks be used for insulation in foundries?

- Yes, insulating fire bricks can be used for insulation in foundries. Insulating fire bricks are specifically designed to have high thermal resistance and low thermal conductivity, making them ideal for applications where insulation is required. In foundries, where high temperatures are involved, insulating fire bricks can be used to line the walls, floors, and roofs to reduce heat loss and improve energy efficiency. They can also help to maintain a uniform temperature throughout the foundry, ensuring consistent heat distribution and preventing heat loss to the surroundings. Additionally, insulating fire bricks are lightweight and easy to install, making them a practical choice for insulation in foundries.

- Q: Are insulating fire bricks resistant to phosphoric acid?

- Insulating fire bricks are generally not resistant to phosphoric acid. Phosphoric acid is a strong acid that can react with and corrode many materials, including fire bricks. While some fire bricks may have a certain level of resistance to acidic environments, it is unlikely that insulating fire bricks would be able to withstand prolonged exposure to phosphoric acid without significant deterioration. It is therefore recommended to use acid-resistant materials, such as acid-resistant bricks or linings, when dealing with phosphoric acid or other strong acids.

- Q: Can insulating fire bricks be used for kiln furniture?

- Yes, insulating fire bricks can be used for kiln furniture. Insulating fire bricks are lightweight, have high insulating properties, and can withstand high temperatures, making them suitable for use as shelves, posts, or supports in kilns. They help to conserve energy, improve heat distribution, and protect the kiln structure.

- Q: Can insulating fire bricks be used for chimney lining?

- Yes, insulating fire bricks can be used for chimney lining. Insulating fire bricks are specifically designed to withstand high temperatures and are excellent at retaining heat. They have a low thermal conductivity which helps to prevent heat loss and improve the efficiency of the chimney. Additionally, insulating fire bricks are resistant to cracking and spalling, making them a durable option for chimney lining. However, it is important to ensure that the insulating fire bricks used are suitable for the specific type of chimney and comply with local building codes and regulations.

- Q: How do insulating fire bricks affect the overall fire rating of a structure?

- Insulating fire bricks can significantly enhance the overall fire rating of a structure. These bricks have excellent thermal insulation properties, which help in reducing heat transfer from one side of the brick to another. By minimizing heat transmission, they effectively slow down the spread of fire, preventing it from rapidly spreading throughout the structure. This delay in fire propagation gives occupants more time to evacuate and firefighters additional time to control the blaze, thereby improving the overall fire safety of the building.

Send your message to us

Insulating Fire Brick - Insulation Brick, Insulating Brick, GJM23, GJM26, GJM28, GJM30, GJM32

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords