Insulating Fire Brick - Refractory Thermal Insulating Light Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Light Brick Thermal Insulating Fire Brick

High alumina insulating fire brick is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina Insulating Fire Brick are made of selected high alumina bauxite, kaolin caly, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature.

Product Applications:

High alumina insulating fire brick are ideal for use in the below applications

Building materials for blast furnace

Building materials for hot-blast stove

Building materials for coke oven

Building materials for steel making furnace

For construction material in steel industry

For ladle

Product Advantages:

CNBM has success in its High alumina insulating fire brick due to their cost-effectiveness and excellent insulating properties. The refractoriness of magnesia chrome bricks are more than 2000°C, and the refractory under load is a above 1550°C.Good steady volume in high temperature, the performance of meeting sudden cold and sudden hot is better than magnesia bricks.

Main Product Features:

Excellent thermal stability

High refractoriness under load

Chemical stability and anti-corrision

Small high temperature creep rate

Excellent thermal shock resistance

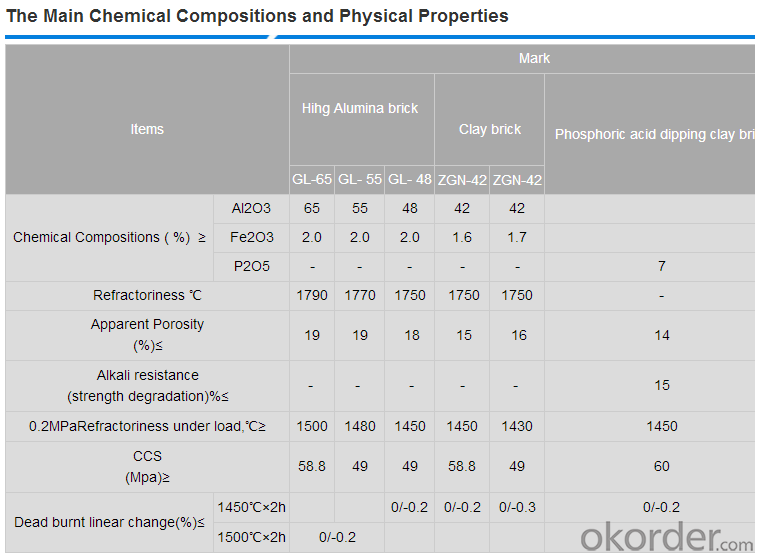

Product Specifications:

FAQ:

Q1: Are you a manufacture or trader?

A1: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A2: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A3: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A4: We have our own factories and excellent technical team, and we accept OEM service.

Product Picture

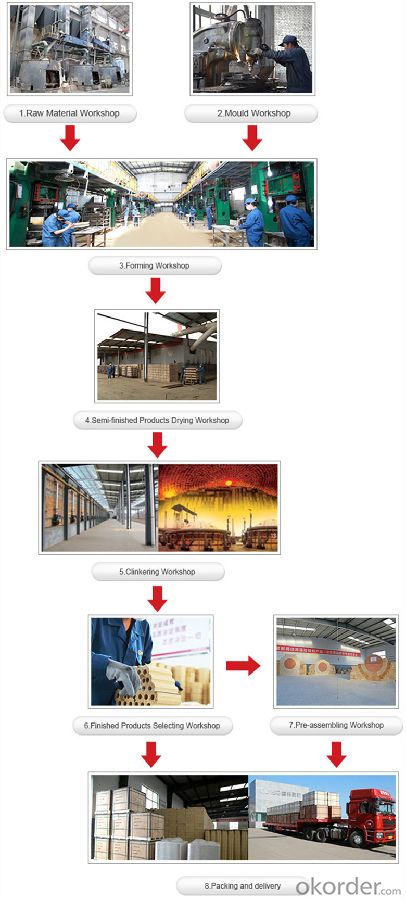

Produce Processing

- Q: Can insulating fire bricks be used in refractory linings for boilers?

- Yes, insulating fire bricks can be used in refractory linings for boilers. Insulating fire bricks are specifically designed to have low thermal conductivity, which makes them ideal for applications where heat insulation is required. In boiler systems, insulating fire bricks can be used to line the walls, roof, and floor of the combustion chamber, as well as the flue gas passages. By using insulating fire bricks in these areas, the heat loss from the boiler can be minimized, resulting in improved energy efficiency. Additionally, insulating fire bricks are lightweight and easy to install, making them a convenient choice for boiler refractory linings.

- Q: Is sintering insulation brick good or concrete porous brick good?

- As with the expansion screw, it depends on what to connect, and go in is no problem, the key is that the carrying capacity is not very high, if you do steel support, pull and so on, it is recommended to use concrete.

- Q: Can insulating fire bricks be used for insulation in flues?

- Insulating fire bricks are created with the specific purpose of being used in high-temperature settings, such as furnaces, kilns, and various industrial environments. Their main function is to effectively insulate heat and prevent heat loss. However, it is important to note that they are not suitable for use in flues. Flues are exposed to extreme temperatures, corrosive gases, and the possibility of accumulation of soot and creosote. The conditions in flues are not compatible with insulating fire bricks, as they are not designed to withstand such harsh elements. Consequently, when exposed to the acidic and corrosive gases generated by combustion, these bricks may deteriorate or develop cracks over time. To ensure proper insulation in flues, it is advisable to opt for materials that are specifically manufactured for this purpose, such as refractory cement or ceramic fiber insulation. These materials are better equipped to withstand the challenging conditions encountered in flues and are more capable of providing effective insulation while maintaining the safety and durability of the flue system.

- Q: Can insulating fire bricks be used for insulation in industrial chimneys?

- Yes, insulating fire bricks can be used for insulation in industrial chimneys. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation. Their low thermal conductivity helps to reduce heat loss, increase energy efficiency, and maintain high temperatures inside the chimney. Consequently, they are commonly used in industrial chimneys to enhance insulation and improve overall performance.

- Q: Are insulating fire bricks resistant to thermal spalling?

- Yes, insulating fire bricks are resistant to thermal spalling.

- Q: Can insulating fire bricks be used in the construction of hot air generators?

- Indeed, the utilization of insulating fire bricks is applicable in the fabrication of hot air generators. Specifically engineered to endure extreme temperatures and deliver exceptional thermal insulation, insulating fire bricks are well-suited for incorporation into hot air generators. These generators necessitate insulation to uphold elevated temperatures and avert heat dissipation. By diminishing heat transfer to the surroundings, insulating fire bricks effectively enhance the efficiency and functionality of hot air generators. Furthermore, their lightweight nature, effortless installation, and long-lasting durability contribute to their widespread adoption in diverse industrial sectors, including the construction of hot air generators.

- Q: Can insulating fire bricks be used in the construction of industrial furnaces?

- Yes, insulating fire bricks can be used in the construction of industrial furnaces. Insulating fire bricks are specifically designed to withstand high temperatures and thermal shocks, making them suitable for use in furnaces where temperatures can reach extremely high levels. These bricks have low thermal conductivity, which helps to minimize heat loss and improve energy efficiency in the furnace. Additionally, insulating fire bricks are lightweight and easy to handle, making them convenient for construction purposes. Overall, their excellent insulation and heat-resistant properties make insulating fire bricks an ideal choice for industrial furnace construction.

- Q: Can insulating fire bricks be used in electric furnaces?

- Indeed, electric furnaces can utilize insulating fire bricks. These bricks are intentionally engineered to possess a minimal thermal conductivity, rendering them highly suitable for situations necessitating heat containment or insulation. Electric furnaces necessitate insulation to thwart heat dissipation and enhance energy efficacy. Insulating fire bricks can endure extreme temperatures and possess exceptional insulation attributes, rendering them a fitting choice for electric furnace applications. Moreover, their lightweight nature and effortless installation make them a favored option for electric furnace insulation.

- Q: Can insulating fire bricks be used in boilers for residential heating?

- Insulating fire bricks can indeed be utilized for residential heating boilers. These bricks are specifically engineered to endure elevated temperatures and offer superior thermal insulation properties. Their utilization in boiler and furnace construction is widespread due to their remarkable heat retention capabilities and ability to prevent heat dissipation. Consequently, the incorporation of these bricks aids in enhancing the energy efficiency of the boiler system by minimizing heat transfer to the surroundings, resulting in more effective heating and reduced energy consumption. Furthermore, the durability and resistance to thermal shock exhibited by insulating fire bricks make them ideal for withstanding the intense temperatures and rapid temperature fluctuations typically encountered in boilers. Consequently, their implementation in residential heating boilers serves to enhance both performance and energy efficiency.

- Q: Are insulating fire bricks environmentally friendly?

- Insulating fire bricks can be considered environmentally friendly to a certain extent. These bricks are made from natural materials such as clay, shale, and other minerals, which are abundant and readily available. This means that they do not contribute to the depletion of natural resources. Additionally, insulating fire bricks are designed to have low thermal conductivity, which helps in reducing energy consumption. By using these bricks, buildings can be better insulated, resulting in lower heating and cooling requirements and subsequently reducing greenhouse gas emissions. However, the manufacturing process of insulating fire bricks does have some environmental impacts. The firing process requires high temperatures, which can contribute to air pollution and greenhouse gas emissions. Furthermore, the extraction of raw materials for these bricks may involve some environmental disturbance. To truly assess the environmental friendliness of insulating fire bricks, it is important to consider the entire life cycle, including the extraction of raw materials, manufacturing process, transportation, and disposal. Additionally, comparing them to alternative insulation materials can provide a more comprehensive perspective on their environmental impact. In conclusion, while insulating fire bricks have certain eco-friendly characteristics like being made from natural materials and reducing energy consumption, their overall environmental impact should be evaluated in a holistic manner.

Send your message to us

Insulating Fire Brick - Refractory Thermal Insulating Light Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords