Insulating Fire Brick - GJM23 for Hot Face Lining

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Insulating Firebricks

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Feature of Insulating Firebricks

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application of Insulating Firebricks

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

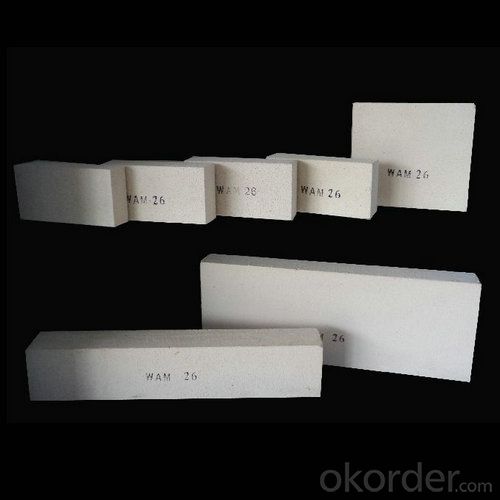

Images of Insulating Firebricks

Technical Data of Insulating Firebricks

INSULATING FIRE BRICK---GJM23

Classification Temperature (℉/℃) 2300/1260

Bulk Density (g/cm3) ≤0.5

Thermal Conductivity

800℃, W/m.K ≤0.18

1000℃, W/m.K ≤0.20

Reheating Linear Change (%) 1230℃×12h

≤0.5

Chemical Composition (%)

Al2O3 ≥45

Fe2O3 ≤1.0

Company Introduction

Who CNBM is

CNBM is a Fortune 500 and a governmental owned National Building Material company in Beijing, China.

What CNBM Can Do

We can supply ALL KINDS OF REFRACTORIES BRICK/CASTABLE and CERAMIC FIBER PRODUCTS in high quality and competitive price.

What Certification CNBM Have

FAQ

If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

How do you control the products quality?

With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervisor.

I’m not satisfied with the refractory materials I used before, can you propose more suitable pro

Yes. Please give us the problems you faced, your requirements and the technical data of the products you used before. That we will give you our suggestion and propose the solution based on your special requirements.

What’s the lead time for my order?

It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Can you offer Door-to-Door delivery?

Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

What is the minimum quantity?

There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

- Q: Can insulating fire bricks be used for insulation in incinerators?

- Yes, insulating fire bricks can be used for insulation in incinerators. These bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for use in incinerators to minimize heat loss and improve energy efficiency.

- Q: Can insulating fire bricks be used to line industrial boilers?

- Yes, insulating fire bricks can be used to line industrial boilers. Insulating fire bricks are specially designed to have low thermal conductivity, which helps to minimize heat loss and improve energy efficiency in the boiler system. These bricks are made from lightweight materials such as clay and alumina, which have excellent insulation properties. By lining the interior of the boiler with insulating fire bricks, the heat generated by the combustion process can be contained within the boiler, resulting in higher heating efficiency and reduced fuel consumption. Additionally, insulating fire bricks can withstand high temperatures and thermal shocks, making them suitable for the harsh operating conditions often encountered in industrial boilers. Overall, using insulating fire bricks as a lining material in industrial boilers can contribute to improved energy efficiency, reduced operating costs, and increased durability of the boiler system.

- Q: Can insulating fire bricks be used for flooring insulation?

- Insulating fire bricks are primarily designed for high-temperature applications such as kilns, furnaces, and fireplaces. While they can provide excellent thermal insulation, they may not be the best choice for flooring insulation. Insulating fire bricks are typically softer and less durable compared to other flooring materials, which can make them susceptible to damage from foot traffic. Additionally, they may not provide sufficient support and stability for the floor, especially in high-traffic areas. For flooring insulation, it is generally recommended to use materials specifically designed for this purpose, such as foam boards, cork, or rubber underlayments. These materials are more resilient, durable, and better suited to withstand the demands of flooring applications. They also offer better noise reduction and moisture resistance, which are important considerations for flooring insulation.

- Q: Are insulating fire bricks resistant to carbon dioxide?

- Insulating fire bricks, also known as refractory bricks, are designed to withstand high temperatures and are generally resistant to various chemicals and gases. However, their resistance to carbon dioxide may vary depending on the specific type and composition of the insulating fire brick. Carbon dioxide (CO2) is a non-flammable gas that is usually present in the atmosphere and is released during the combustion of carbon-based fuels. In most cases, insulating fire bricks have a high resistance to carbon dioxide due to their high melting point and the presence of refractory materials such as alumina and silica. However, prolonged exposure to high concentrations of carbon dioxide, especially at elevated temperatures, can cause some insulating fire bricks to undergo chemical reactions that may lead to degradation or reduced performance. It is important to consider the specific application and environment in which the insulating fire bricks will be used. If the insulating fire bricks are part of a furnace or kiln that generates significant amounts of carbon dioxide, it is advisable to choose bricks specifically designed for such conditions. These bricks may have additional protective coatings or higher chemical resistance to ensure their longevity and performance. In summary, while insulating fire bricks generally have good resistance to carbon dioxide, it is important to consider the specific type of brick and the conditions under which it will be used to ensure optimal performance and longevity.

- Q: Can insulating fire bricks be used in combination with other insulation materials?

- Yes, insulating fire bricks can be used in combination with other insulation materials. They can be used as a primary insulation layer or in conjunction with other materials such as ceramic fiber insulation or refractory coatings to enhance insulation efficiency and achieve higher temperature resistance. This combination of insulation materials can provide better thermal insulation properties and increased energy efficiency in various applications such as furnaces, kilns, and high-temperature industrial processes.

- Q: Are insulating fire bricks resistant to saltwater?

- Insulating fire bricks are typically not resistant to saltwater. Saltwater contains high levels of salt, which can cause corrosion and degradation of the material over time. It is recommended to use refractory materials that are specifically designed to withstand saltwater environments if you are looking for a solution that is resistant to corrosion.

- Q: Are insulating fire bricks resistant to chlorine gas?

- Yes, insulating fire bricks are generally resistant to chlorine gas. Insulating fire bricks are made from refractory materials, which are designed to withstand high temperatures and resist chemical corrosion. Chlorine gas is a highly reactive substance and can cause corrosion or damage to many materials. However, insulating fire bricks have a high resistance to chemical attack, making them suitable for applications where they may come into contact with chlorine gas. It is important to note that the specific composition and quality of the insulating fire bricks can vary, so it is always recommended to consult the manufacturer or supplier for specific information regarding their resistance to chlorine gas.

- Q: Can insulating fire bricks be used in the construction of coke ovens?

- Yes, insulating fire bricks can be used in the construction of coke ovens. These bricks are specifically designed to withstand high temperatures and provide excellent insulation, making them suitable for coke ovens where extreme heat is generated during the coke-making process. The insulating properties of these bricks help maintain the desired temperature inside the oven while minimizing heat loss, resulting in more efficient and effective coke production.

- Q: Are insulating fire bricks resistant to hydrofluoric acid?

- Insulating fire bricks are not resistant to hydrofluoric acid. Hydrofluoric acid is a highly corrosive substance that can attack and dissolve many materials, including fire bricks. It is important to handle hydrofluoric acid with extreme caution and use appropriate protective equipment when working with this hazardous substance.

- Q: Are insulating fire bricks suitable for use in wood-fired ovens?

- Yes, insulating fire bricks are suitable for use in wood-fired ovens. These bricks are specifically designed to withstand high temperatures, making them ideal for use in ovens or other heat-intensive applications. Insulating fire bricks have excellent thermal insulation properties, which helps to retain heat inside the oven and ensures a more efficient cooking process. Additionally, these bricks have a low thermal conductivity, meaning they transfer less heat to the external surfaces, resulting in a safer and more comfortable cooking experience. Therefore, using insulating fire bricks in wood-fired ovens can provide better heat retention, energy efficiency, and improved overall performance.

Send your message to us

Insulating Fire Brick - GJM23 for Hot Face Lining

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords