Insulating Fire Brick GJM23 26 28 30 for Different Applications in Steel Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 watt

- Supply Capability:

- 1000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

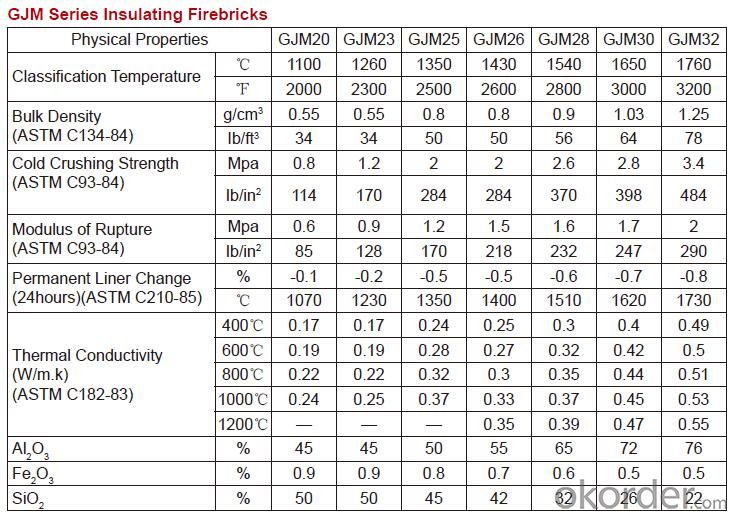

CMAX insulating firebricks are classified under temperature between 1100℃ to 1700℃, manufactured from high purity alumina clay.

Features

◆Light weight and low thermal conductivity

◆Low heat storage

◆Low iron and impurities

◆High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

Technical Data

This information, subject to change, is offered solely for your consideration. Users of our products should make their

own tests to determine the suitability of each product for their particular purposes.

Company Information

CNBM International Corp., established in 2004, is the business entity for international business and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

Production Control

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q: Coke burns in a closed house. Will anyone suffocate in it?

- Not suffocating in the short term, will suffocate for a long time.

- Q: How do insulating fire bricks affect heating or cooling times?

- Insulating fire bricks help to reduce heating or cooling times by providing excellent thermal insulation. They have low thermal conductivity, which means they minimize heat transfer between the hot or cold surface and the surrounding environment. As a result, insulating fire bricks can effectively retain heat or coldness, allowing for faster heating or cooling of the desired area.

- Q: Do insulating fire bricks require any special sealing or caulking?

- In certain applications, insulating fire bricks typically require special sealing or caulking. Despite their ability to withstand high temperatures and provide excellent thermal insulation, insulating fire bricks can still be vulnerable to moisture infiltration and atmospheric gases in specific environments. To address these risks, sealing or caulking is often necessary. To seal or caulk insulating fire bricks, specialized refractory materials or compounds that can withstand high temperatures and create an airtight barrier are used. This sealing process helps prevent moisture, gases, and other contaminants from compromising the insulating properties of the bricks. The specific sealing or caulking method depends on the application and type of insulating fire bricks being used. Common techniques include using high-temperature silicone sealants, refractory mortars, or coatings. These materials are specifically designed to endure the extreme temperatures found in high-heat environments. It is important to consult the manufacturer's guidelines or seek professional advice when determining the appropriate sealing or caulking method for insulating fire bricks. Proper sealing ensures the insulation's longevity, effectiveness, and overall performance and safety of the application.

- Q: Can insulating fire bricks be used in refractory linings for blast furnaces?

- Yes, insulating fire bricks can be used in refractory linings for blast furnaces. These bricks have high insulating properties, which help to reduce heat loss and improve energy efficiency in the furnace. Additionally, they offer good thermal shock resistance and can withstand the extreme temperatures and harsh conditions within the blast furnace.

- Q: Can insulating fire bricks be used for insulation in boilers?

- Yes, insulating fire bricks can be used for insulation in boilers. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. They have low thermal conductivity, meaning they can effectively reduce heat loss and improve the energy efficiency of boilers. Additionally, insulating fire bricks are lightweight and easy to install, making them a popular choice for insulation in boilers. They can help maintain high temperatures inside the boiler, allowing for efficient combustion and heat transfer, while also protecting the outer structure from excessive heat. Overall, insulating fire bricks are a reliable and effective choice for insulation in boilers.

- Q: Can insulating fire bricks be used in the construction of glass slump molds?

- Yes, insulating fire bricks can be used in the construction of glass slump molds. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in kilns and other heat-intensive applications like glass slumping. Their insulating properties help to maintain a consistent temperature during the slumping process, ensuring the glass molds are formed correctly.

- Q: Can insulating fire bricks be used in the construction of lime calciners?

- Indeed, the utilization of insulating fire bricks is feasible when constructing lime calciners. Lime calciners necessitate elevated temperatures for lime production, and insulating fire bricks are specifically engineered to endure and preserve heat. These bricks possess a reduced thermal conductivity, which effectively insulates the calciner and impedes heat dissipation. Furthermore, insulating fire bricks are lightweight, facilitating their handling and installation during the lime calciners' construction process.

- Q: Can insulating fire bricks be used for insulation in cryogenic applications?

- Yes, insulating fire bricks can be used for insulation in cryogenic applications. Insulating fire bricks are made from lightweight refractory materials with low thermal conductivity, which makes them highly effective in reducing heat transfer. Cryogenic applications require insulation materials that can withstand extremely low temperatures and prevent heat leakage. Insulating fire bricks have excellent thermal stability and can maintain their insulation properties even at cryogenic temperatures. They are commonly used in cryogenic storage tanks, pipelines, and other equipment to provide insulation and minimize heat transfer.

- Q: Can insulating fire bricks be used for pizza ovens?

- Yes, insulating fire bricks can be used for pizza ovens. Insulating fire bricks are designed to withstand high temperatures, making them a suitable choice for creating a well-insulated and efficient pizza oven. They help retain heat, allowing the oven to reach and maintain the desired temperature for baking delicious pizzas.

- Q: Can insulating fire bricks be used in cement kilns?

- Indeed, in cement kilns, insulating fire bricks find their utility. These bricks are specifically engineered with a low thermal conductivity, rendering them an excellent choice for insulating environments that endure high temperatures, like cement kilns. By employing these bricks, heat loss can be minimized, thereby enhancing energy efficiency within the kiln. Furthermore, their lightweight composition facilitates ease of handling and installation in the kiln. Nevertheless, it is crucial to carefully select insulating fire bricks that align with the unique operating conditions and demands of the cement kiln to guarantee utmost performance and durability.

Send your message to us

Insulating Fire Brick GJM23 26 28 30 for Different Applications in Steel Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 watt

- Supply Capability:

- 1000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords