Insulating Fire Brick GJM23 - High-Performance Insulation Range

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Insulating Firebricks

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Feature of Insulating Firebricks

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

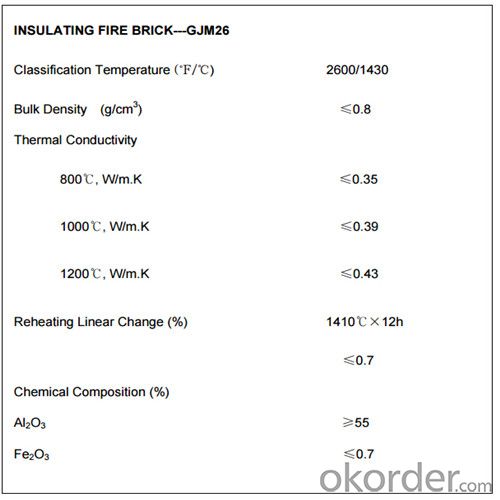

Technical Data of Insulating Fire Brick

What are the excellent features of Insulating Fire Brick?

High heat resistance and durability

Excellent insulating properties

Excellent resistance to thermal shock

Low thermal conductivity

Low heat storage

Excellent construction/compressive strength

Particularly suited to highest temperature applications above 1600°C or 2800°F

Structural integrity capable of dealing with erosive and abrasive environments

Low impurity

Precise dimensions

Image of Insulating Fire Brick

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements. From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: Can insulating fire bricks be used in chimney lining?

- Yes, insulating fire bricks can be used in chimney lining. They are designed to withstand high temperatures and provide insulation, making them an ideal choice for lining chimneys to improve heat retention and prevent heat transfer to surrounding structures.

- Q: How do insulating fire bricks help to conserve energy?

- Insulating fire bricks help to conserve energy in several ways. Firstly, these bricks are made from materials that have high thermal resistance, which means they are excellent at preventing the transfer of heat. By using insulating fire bricks in the construction of furnaces, kilns, or any other heat-generating equipment, they act as a barrier that prevents the loss of heat to the surroundings. This, in turn, reduces the amount of energy required to maintain a consistent temperature within the equipment. Additionally, insulating fire bricks have low thermal conductivity, meaning they do not conduct heat easily. As a result, they prevent the transfer of heat from the hot side to the cold side, minimizing heat loss and ensuring that more energy is utilized for the intended purpose rather than being wasted. Furthermore, insulating fire bricks have high heat capacity, allowing them to absorb and store heat efficiently. This property is beneficial as it helps to stabilize temperature fluctuations by releasing stored heat slowly over time, reducing the need for constant energy input to maintain the desired temperature. In summary, insulating fire bricks help to conserve energy by reducing heat loss, minimizing heat transfer, and stabilizing temperature fluctuations. By implementing these bricks in various heat-generating applications, energy consumption can be significantly reduced, leading to cost savings and a more sustainable use of resources.

- Q: Are insulating fire bricks suitable for use in carbon black furnaces?

- Yes, insulating fire bricks are suitable for use in carbon black furnaces. These bricks are known for their high insulation properties, which help in maintaining high temperatures inside the furnace while preventing heat loss. Additionally, insulating fire bricks are designed to withstand extreme temperatures and chemical reactions, making them a suitable choice for carbon black furnaces that operate under high heat and harsh conditions.

- Q: Are there any construction waste materials for composite thermal insulation bricks?

- Material production of ordinary light insulating brick clay, high alumina high strength low iron bead brick, mullite, high aluminum light insulating refractory brick, diatomite insulating refractory brick.

- Q: Can insulating fire bricks be used in the construction of hot air generators?

- Yes, insulating fire bricks can be used in the construction of hot air generators. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation. This makes them suitable for use in hot air generators, which require insulation to maintain high temperatures and prevent heat loss. Insulating fire bricks help to increase the efficiency and performance of hot air generators by reducing heat transfer to the surroundings. Additionally, these bricks are lightweight, easy to install, and durable, making them a popular choice for various industrial applications including the construction of hot air generators.

- Q: Are insulating fire bricks suitable for outdoor use?

- Insulating fire bricks are not typically suitable for outdoor use due to their lower density and higher porosity compared to other types of bricks. These bricks are designed for use in high-temperature applications such as furnaces and kilns, where they provide excellent insulation properties. However, when exposed to the elements, insulating fire bricks may absorb moisture and be prone to cracking or deteriorating over time. For outdoor applications, it is generally recommended to use dense fire bricks or other types of bricks that are specifically designed for outdoor use, as they have greater durability and resistance to weather conditions.

- Q: Are insulating fire bricks suitable for use in residential fireplaces?

- Yes, insulating fire bricks are suitable for use in residential fireplaces. They are designed to withstand high temperatures and provide insulation, making them an ideal choice for ensuring the safety and efficiency of a residential fireplace.

- Q: Can insulating fire bricks be used for insulation in glass manufacturing?

- Yes, insulating fire bricks can be used for insulation in glass manufacturing. Insulating fire bricks offer high-temperature resistance and low thermal conductivity, making them suitable for insulation and maintaining consistent temperatures during glass manufacturing processes.

- Q: What is the typical thermal diffusivity of an insulating fire brick?

- The typical thermal diffusivity of an insulating fire brick can vary depending on the specific composition and manufacturing process of the brick. However, as a general guideline, insulating fire bricks typically have thermal diffusivity values ranging from around 0.05 to 0.2 mm²/s. Thermal diffusivity is a measure of how quickly heat can be conducted through a material. A low thermal diffusivity indicates that the material is a good insulator, as it does not conduct heat rapidly. Insulating fire bricks are designed to have low thermal diffusivity in order to minimize heat transfer and provide effective insulation in high-temperature applications, such as in furnaces, kilns, and fireplaces. It is worth noting that the specific thermal diffusivity of an insulating fire brick can be influenced by factors such as the type of raw materials used, the manufacturing process (including the firing temperature and duration), and any additives or coatings applied to enhance insulation properties. Therefore, it is important to consult the manufacturer's specifications or conduct specific tests to determine the thermal diffusivity of a particular insulating fire brick.

- Q: Can insulating fire bricks be used in hydrogen furnaces?

- Insulating fire bricks can be used in hydrogen furnaces, but it is important to note that not all types of insulating fire bricks are suitable for this application. Hydrogen is a highly reactive gas and can cause certain materials to degrade or react, leading to safety concerns and potential damage to the furnace. When selecting insulating fire bricks for use in hydrogen furnaces, it is crucial to choose bricks that are specifically designed for high-temperature and corrosive environments. These bricks should be made from materials that are resistant to hydrogen embrittlement and have low reactivity with hydrogen. Silicon carbide (SiC) and alumina-silica (Al2O3-SiO2) are commonly used materials for insulating fire bricks in hydrogen furnaces. These materials have good resistance to high temperatures and are chemically stable in the presence of hydrogen. It is also important to consider the density and porosity of the insulating fire bricks. Low-density bricks with high porosity are preferred for hydrogen furnaces as they provide better thermal insulation and reduce the risk of hydrogen leakage. Overall, while insulating fire bricks can be used in hydrogen furnaces, it is crucial to select the appropriate type of bricks that are specifically designed for high-temperature and corrosive environments, and have good resistance to hydrogen embrittlement and reactivity. Consulting with experts in the field and following the manufacturer's guidelines is highly recommended to ensure the safe and efficient operation of the hydrogen furnace.

Send your message to us

Insulating Fire Brick GJM23 - High-Performance Insulation Range

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords