Insulating Fire Brick 65% Al2O3 Min High Alumina

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

65% Al2O3 Min High Alumina Insulating Fire Brick

High alumina insulating fire brick is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina Insulating Fire Brick are made of selected high alumina bauxite, kaolin caly, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature.

Product Applications:

High alumina insulating fire brick are ideal for use in the below applications

Building materials for blast furnace

Building materials for hot-blast stove

Building materials for coke oven

Building materials for steel making furnace

For construction material in steel industry

For ladle

Product Advantages:

CNBM has success in its High alumina insulating fire brick due to their cost-effectiveness and excellent insulating properties. The refractoriness of magnesia chrome bricks are more than 2000°C, and the refractory under load is a above 1550°C.Good steady volume in high temperature, the performance of meeting sudden cold and sudden hot is better than magnesia bricks.

Main Product Features:

Excellent thermal stability

High refractoriness under load

Chemical stability and anti-corrision

Small high temperature creep rate

Excellent thermal shock resistance

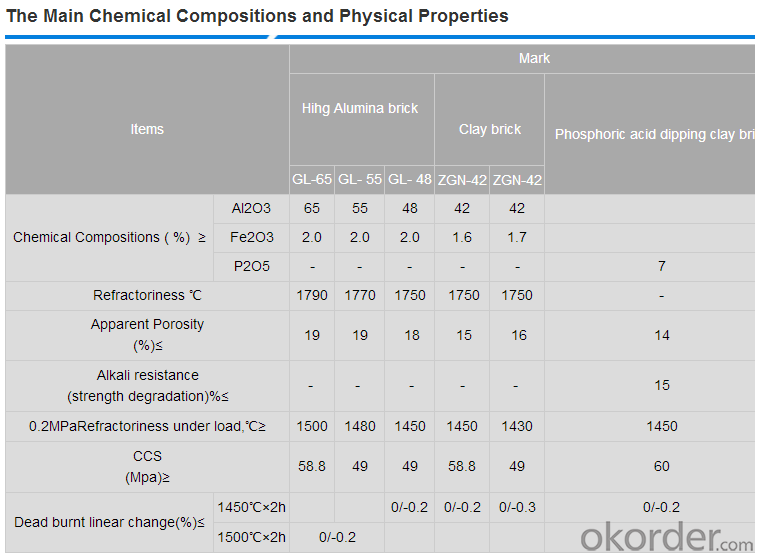

Product Specifications:

FAQ:

Q1: Are you a manufacture or trader?

A1: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A2: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A3: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A4: We have our own factories and excellent technical team, and we accept OEM service.

Product Picture

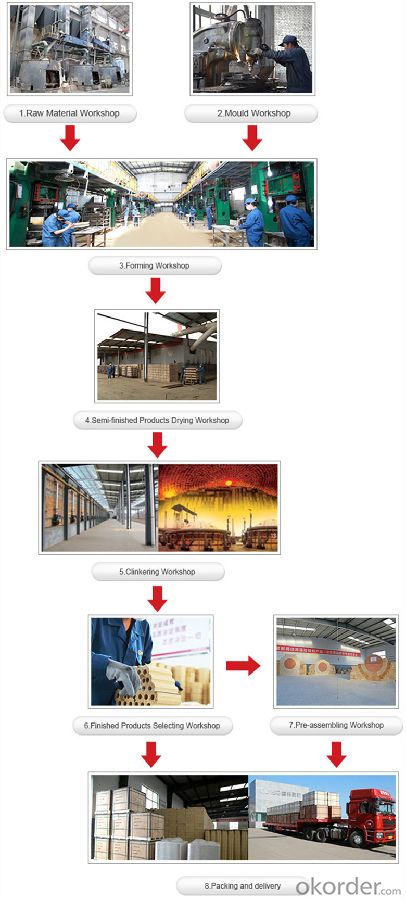

Produce Processing

- Q: How do insulating fire bricks compare to other insulation materials?

- Insulating fire bricks are superior to other insulation materials in terms of their high heat resistance, durability, and ability to withstand extreme temperatures. They offer excellent thermal insulation properties, low thermal conductivity, and are capable of retaining heat for prolonged periods. Compared to traditional insulation materials like fiberglass and mineral wool, insulating fire bricks provide superior insulation performance and are more suitable for applications requiring high-temperature resistance, such as furnaces, kilns, and industrial ovens.

- Q: Are insulating fire bricks suitable for use in chimneys and fireplaces?

- Chimneys and fireplaces can benefit from the use of insulating fire bricks. These bricks are specifically designed to endure high temperatures and offer superb thermal insulation. They are crafted from lightweight materials, such as ceramic fibers or lightweight aggregates, aiding in heat retention and preventing heat loss. Consequently, they are well-suited for lining chimneys and fireplaces, as they are capable of effectively trapping and emitting heat, resulting in increased energy efficiency. Moreover, insulating fire bricks possess low thermal conductivity, enabling them to resist cracking and spalling that may occur due to sudden changes in temperature. This ensures their longevity and durability. Overall, insulating fire bricks are a dependable and efficient choice for bolstering the performance and safety of chimneys and fireplaces.

- Q: Are insulating fire bricks resistant to warping?

- Insulating fire bricks are known for their resistance to warping. They are specifically designed to withstand high temperatures and thermal shocks, preventing any potential warping. These bricks are crafted using lightweight materials like clay, silica, and alumina, which are combined with additives to enhance their insulation capabilities. Moreover, these additives not only contribute to the brick's insulation, but also aid in its resistance against warping. Furthermore, insulating fire bricks undergo a meticulous manufacturing process that ensures dimensional stability and reduces the risk of warping. It is worth mentioning, however, that prolonged and extreme exposure to high temperatures may still result in some warping, albeit to a lesser extent than other brick types.

- Q: Can insulating fire bricks be used as a backup insulation material?

- Yes, insulating fire bricks can be used as a backup insulation material. Insulating fire bricks are designed to have a high thermal resistance and low thermal conductivity, making them suitable for providing insulation in high-temperature applications. They can be used as backup insulation behind other refractory materials to enhance insulation properties and improve the overall thermal efficiency of a system.

- Q: How do insulating fire bricks compare to other insulation materials like ceramic fiber?

- Insulating fire bricks are generally denser and more durable compared to ceramic fiber insulation materials. While ceramic fiber offers excellent thermal insulation and is lightweight, insulating fire bricks provide better resistance to high temperatures and mechanical stress. Additionally, insulating fire bricks have lower thermal conductivity and higher compressive strength, making them suitable for applications that require long-term thermal insulation and structural support.

- Q: Can insulating fire bricks be used in the construction of lime production linings?

- Yes, insulating fire bricks can be used in the construction of lime production linings. Insulating fire bricks are designed to have low thermal conductivity, which makes them excellent for applications where heat insulation is required. In lime production, high temperatures are required for the calcination process. Using insulating fire bricks in the construction of lime production linings helps to reduce heat loss and improve energy efficiency. Additionally, insulating fire bricks are lightweight and easy to handle, which makes them suitable for lining various parts of lime kilns and other equipment used in the lime production process. Overall, using insulating fire bricks in lime production linings can help to optimize the production process and improve the overall performance of lime production facilities.

- Q: Can insulating fire bricks be used in the construction of coke ovens?

- Yes, insulating fire bricks can be used in the construction of coke ovens. Insulating fire bricks are specially designed to withstand high temperatures and provide excellent thermal insulation. Coke ovens operate at extremely high temperatures, typically around 2000 degrees Fahrenheit, and require materials that can withstand these conditions. Insulating fire bricks have low thermal conductivity, which means they can effectively prevent heat transfer between the oven's interior and exterior. This helps to maintain the high temperatures required for the carbonization of coal in the coke oven, while also minimizing heat loss. Furthermore, insulating fire bricks are lightweight and have high strength, making them ideal for use in the construction of coke ovens. Their lightweight nature allows for easier installation and reduces the overall weight of the structure. Their high strength ensures that they can withstand the harsh operating conditions of the coke oven without cracking or crumbling. In summary, insulating fire bricks are a suitable choice for the construction of coke ovens due to their ability to withstand high temperatures, provide thermal insulation, and offer durability.

- Q: Can insulating fire bricks be used in the construction of glass bottle production furnaces?

- Insulating fire bricks have the capability to be utilized in the construction of glass bottle production furnaces. These bricks are specifically designed to withstand high temperatures and offer exceptional thermal insulation. They are commonly employed in applications that necessitate heat retention and energy efficiency, like furnaces. By incorporating insulating fire bricks into the construction of glass bottle production furnaces, the generated heat during the glass-making process can be effectively contained within the furnace, resulting in diminished heat loss and enhanced energy efficiency. Consequently, this can lead to cost savings and improved production performance. Furthermore, insulating fire bricks can aid in safeguarding the structural integrity of the furnace by minimizing thermal stress and preventing heat transfer to the surrounding environment. In summary, the utilization of insulating fire bricks in glass bottle production furnaces can contribute to a more efficient and long-lasting furnace operation.

- Q: Can insulating fire bricks be used in high-temperature ducts?

- Insulating fire bricks can indeed be used in high-temperature ducts. These bricks are specially designed to withstand extreme temperatures, making them an ideal choice for applications where heat retention and insulation are crucial. With their low thermal conductivity and high resistance to thermal shock, insulating fire bricks can effectively trap heat within the ducts, preventing any loss of energy and ensuring efficient heat transfer. Additionally, their lightweight nature makes them easy to install and handle, while their durability allows them to withstand the harsh conditions of high-temperature environments. Overall, insulating fire bricks are a reliable and effective solution for insulating high-temperature ducts.

- Q: Are insulating fire bricks suitable for insulation in chemical reactors?

- Due to their exceptional thermal properties and resistance to high temperatures, insulating fire bricks are commonly employed for insulation in chemical reactors. These bricks, which are manufactured from lightweight refractory materials like alumina, silica, and other minerals, effectively impede heat transfer and provide insulation. Furthermore, they possess low thermal conductivity and high heat capacity, enabling them to minimize heat loss and maintain consistent temperatures within the reactor. Chemical reactors often operate at elevated temperatures and may contain corrosive or reactive substances. Insulating fire bricks can withstand these harsh conditions and safeguard the reactor against external heat sources. They are chemically inert and corrosion-resistant, making them suitable for use with various chemicals and reactants. Additionally, insulating fire bricks exhibit a low thermal expansion coefficient, allowing them to endure thermal cycling without cracking or distorting. This characteristic is crucial in chemical reactors where temperature fluctuations are frequent and can potentially harm the equipment. In conclusion, insulating fire bricks are a popular choice for insulation in chemical reactors due to their thermal insulation properties, resistance to chemicals, and ability to withstand high temperatures and thermal cycling. Their usage aids in enhancing the efficiency and safety of chemical processes by maintaining optimal operating conditions within the reactor.

Send your message to us

Insulating Fire Brick 65% Al2O3 Min High Alumina

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords