Injection Carbon FC90-95 with Good and Stable Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Injection Carbon FC90-95 with Good and Stable Quality

25kgs/50kgs/1ton per bag or as buyer's request

Specifications

Injection Carbon FC90-95 with Good and Stable Quality

Calcined Anthracite

Fixed carbon: 90%-95%

S: 0.5% max

Size: 0-3. 3-5.3-15 or as request

Advantage and competitive of caclined anthracite:

Injection Carbon FC90-95 with Good and Stable Quality

1. strong supply capability

2. fast transportation

3. lower and reasonable price for your reference

4.low sulphur, low ash

5.fixed carbon:95% -90%

6..sulphur:lower than 0.3%

General Specification of Calcined Anthracite:

Injection Carbon FC90-95 with Good and Stable Quality

| FC | 95 | 94 | 93 | 92 | 90 |

| ASH | 4 | 5 | 6 | 6.5 | 8.5 |

| V.M. | 1 | 1 | 1 | 1.5 | 1.5 |

| S | 0.3 | 0.3 | 0.3 | 0.35 | 0.35 |

| MOISTURE | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

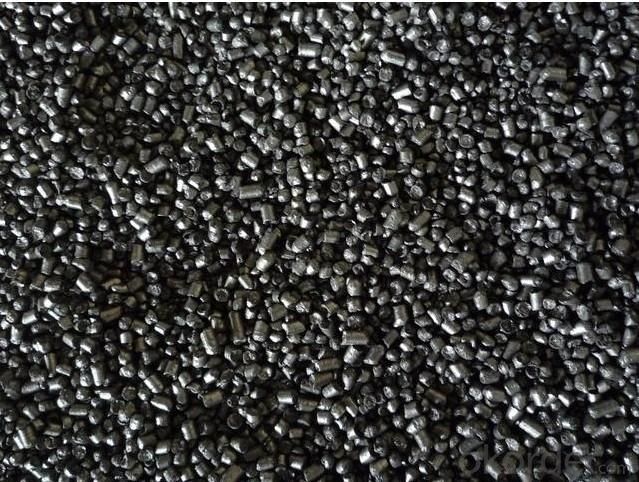

Pictures

Injection Carbon FC90-95 with Good and Stable Quality

FAQ:

Injection Carbon FC90-95 with Good and Stable Quality

What can we do?

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q: How does carbon dating work?

- Carbon dating is a scientific technique used to determine the age of organic materials, such as plants, animals, and human remains. It relies on the fact that carbon-14, a radioactive isotope of carbon, is constantly formed in the atmosphere by cosmic rays. While carbon-14 is present in the atmosphere, it is also absorbed by living organisms through photosynthesis or consumption of other organisms. The ratio of carbon-14 to stable carbon isotopes (carbon-12 and carbon-13) in the atmosphere remains relatively constant, as living organisms maintain a constant level of carbon-14 by exchanging it with the atmosphere through respiration or consumption. However, when an organism dies, it no longer takes in carbon-14, and the existing carbon-14 begins to decay at a predictable rate. Carbon-14 has a half-life of approximately 5,730 years, meaning that after this time, half of the carbon-14 in a sample will have decayed into nitrogen-14. By measuring the remaining carbon-14 in a sample, scientists can calculate how long it has been since the organism died. The process of carbon dating involves several steps. First, a sample is collected from the organic material to be dated, which can be anything from wood to bones to textiles. The sample is then prepared for analysis by removing any contaminants and converting it into a form suitable for measurement. Next, the sample is exposed to a high-energy radiation source, such as a particle accelerator or a nuclear reactor, which causes the carbon atoms in the sample to release small bursts of energy known as beta particles. These particles are detected and measured by sensitive instruments, allowing scientists to determine the amount of carbon-14 remaining in the sample. Finally, this information is used to calculate the age of the organic material. By comparing the ratio of carbon-14 to carbon-12 in the sample to the known ratio in the atmosphere, scientists can estimate the time elapsed since the organism died. Carbon dating is an invaluable tool for archaeologists, paleontologists, and geologists, as it allows them to accurately determine the ages of ancient artifacts, fossils, and geological formations. It has revolutionized our understanding of human history and the natural world, providing us with invaluable insights into the past.

- Q: What are the health effects of carbon monoxide poisoning?

- The human body can experience serious health effects due to carbon monoxide poisoning. When carbon monoxide (CO) is inhaled, it quickly enters the bloodstream and attaches itself to hemoglobin, which is responsible for carrying oxygen in red blood cells. As a result, the blood's ability to transport oxygen throughout the body is reduced, causing oxygen deprivation known as tissue hypoxia. The symptoms of carbon monoxide poisoning can vary depending on the level and duration of exposure. Common symptoms include headache, dizziness, nausea, confusion, weakness, and shortness of breath. These symptoms can easily be mistaken for other illnesses, making carbon monoxide poisoning particularly dangerous as it can go undetected until it reaches critical levels. In severe cases, carbon monoxide poisoning can lead to loss of consciousness, seizures, coma, and even death. Prolonged or repeated exposure to lower levels of carbon monoxide can also result in long-term health problems, including memory issues, difficulty concentrating, mood changes, and cardiovascular complications like heart disease. Certain populations, such as young children, pregnant women, the elderly, and individuals with pre-existing heart or lung conditions, are more vulnerable to the effects of carbon monoxide poisoning. Additionally, being exposed to high levels of carbon monoxide in enclosed spaces like homes with faulty heating systems or car garages can pose a significant risk. To prevent carbon monoxide poisoning, it is crucial to ensure proper ventilation in living spaces and regularly maintain fuel-burning appliances like furnaces, water heaters, and stoves. Installing carbon monoxide detectors in homes is also highly recommended as they can provide early warnings of dangerous gas levels. If carbon monoxide poisoning is suspected, immediate action should be taken to remove oneself from the source of exposure and seek medical attention. Medical professionals may administer oxygen therapy to increase blood oxygen levels and aid in the removal of carbon monoxide from the body. In conclusion, carbon monoxide poisoning can have severe health effects, ranging from mild symptoms to life-threatening conditions. Being aware, taking preventive measures, and responding promptly are crucial in safeguarding individuals from the dangers of carbon monoxide exposure.

- Q: The printed document will be marked on the document name: carbon copy, no combination number, two links...... What's the meaning of this? What is the connection between the infinite and the two? I MMM

- [1] carbon free copy of a few, several refers to a few colors, that is, a few single! Is that a joint edge is what two of what is triple what you said and so on the boundless contact I estimate that he designer or boss tell you to explain things without Bian Lian refers to not say a contact department or (what) no Bian Lian case is a version of the paper change down on it, but the color edge contact is not the same a version of a few joint Bian Lian have changed several times.

- Q: What is the effect of carbon equivalent on welding?

- The carbon equivalent of less than 0.4%, good weldability; in 0.4~0.6%, poor weldability, welding preheating and other measures to prevent cracks; more than 0.6 words, when welding needs higher temperature and strict technical measures! PS: carbon equivalent =C+Mn/6+ (Ni+Cu) /15+ (Cr+Mo+V) /5, Q235 carbon content in 0.14%~0.22% between, widely used by the company seems to be Q235B, carbon content between 0.12~0.20%

- Q: What are fullerenes?

- Fullerenes are a unique class of molecules composed entirely of carbon atoms arranged in a spherical or cage-like structure. They were first discovered in 1985 and have since gained significant attention due to their interesting properties and potential applications in various fields. The most well-known and extensively studied fullerene is the buckminsterfullerene, also known as C60, which consists of 60 carbon atoms forming a hollow sphere resembling a soccer ball. Fullerenes can also have different numbers of carbon atoms, such as C70, C84, or even larger clusters. What makes fullerenes remarkable is their exceptional stability and unique structure. The carbon atoms in a fullerene are interconnected through covalent bonds, forming a closed network of hexagons and pentagons. This arrangement gives fullerenes their characteristic shape and provides them with remarkable mechanical, thermal, and chemical stability. Fullerenes possess a wide range of fascinating properties that make them intriguing for scientific research and technological applications. For instance, they exhibit high electrical conductivity and can act as efficient electron acceptors or donors in organic electronic devices. They also have excellent optical properties, such as strong absorption and emission of light, which have led to their use in solar cells and photovoltaic devices. Moreover, fullerenes have shown potential in medical and biological applications. Their unique cage-like structure allows for encapsulation of other molecules within their hollow interior, making them ideal for drug delivery systems. Fullerenes also possess strong antioxidant properties, which make them potential candidates for various therapeutic treatments. In summary, fullerenes are a fascinating class of carbon-based molecules with unique structures and remarkable properties. Their versatility and potential applications in electronics, energy, medicine, and other fields continue to be explored, making them an exciting area of study in modern science.

- Q: What is carbon offsetting in the automotive industry?

- Carbon offsetting in the automotive industry refers to the practice of compensating for the greenhouse gas emissions produced by vehicles through various methods. As automobiles are a significant contributor to carbon dioxide emissions, carbon offsetting aims to neutralize or reduce the overall impact on the environment. There are several ways in which carbon offsetting can be achieved in the automotive industry. One common method is through the purchase of carbon credits or offsets. These credits represent a reduction or removal of carbon dioxide emissions elsewhere, such as in renewable energy projects or reforestation initiatives. By buying these credits, automotive companies or individuals can offset the emissions produced by their vehicles, effectively balancing out their carbon footprint. Another approach to carbon offsetting involves investing in clean technologies and practices within the automotive sector. This can include the development and implementation of more fuel-efficient engines, hybrid or electric vehicles, or the use of alternative fuels. By reducing the amount of carbon dioxide emitted per kilometer driven, automotive companies can offset their overall emissions and contribute to a greener transportation industry. Additionally, companies in the automotive industry can engage in carbon offsetting by promoting sustainable practices throughout their supply chain. This includes working with suppliers to reduce emissions from the production of vehicle components or implementing energy-efficient manufacturing processes. By addressing emissions throughout the entire lifecycle of a vehicle, from production to disposal, carbon offsetting becomes a comprehensive approach to mitigating the environmental impact of the automotive industry. In conclusion, carbon offsetting in the automotive industry refers to the strategies and actions taken to compensate for the greenhouse gas emissions produced by vehicles. Whether through purchasing carbon credits, investing in clean technologies, or promoting sustainable practices, carbon offsetting aims to reduce the overall impact of automobiles on the environment and contribute to a more sustainable future.

- Q: How do fossil fuels release carbon dioxide when burned?

- When fossil fuels are burned, the carbon atoms present in them combine with oxygen from the air, resulting in the release of carbon dioxide (CO2). This process, known as combustion, produces energy and water vapor as byproducts.

- Q: What is carbon offsetting in the travel industry?

- Carbon offsetting in the travel industry refers to the practice of compensating for the greenhouse gas emissions generated by travel activities, such as flights or accommodations, by investing in projects that reduce or remove an equivalent amount of carbon dioxide from the atmosphere. This can include initiatives like reforestation, renewable energy projects, or energy efficiency improvements. The aim is to mitigate the environmental impact of travel and contribute to the overall goal of reducing carbon emissions.

- Q: How does carbon impact the prevalence of cyclones?

- The prevalence of cyclones is significantly affected by carbon emissions and the subsequent increase in atmospheric carbon dioxide levels. Cyclones, which are also referred to as hurricanes or typhoons, are powerful and destructive weather phenomena that originate over warm ocean waters. The alteration of climate patterns and global warming caused by the increased carbon in the atmosphere, primarily resulting from human activities like burning fossil fuels, play a major role in this. The provision of necessary fuel for cyclones to form and intensify is made possible by the warmer ocean temperatures caused by carbon emissions. As heat is trapped in the atmosphere by carbon dioxide, the surface of the oceans warms up, creating a favorable environment for cyclone development. The availability of more energy for cyclones to grow and become more destructive is directly proportional to the warmth of the ocean waters. Furthermore, carbon emissions contribute to the alteration of climate patterns, leading to changes in atmospheric circulation patterns. These changes have the potential to influence the frequency, intensity, and track of cyclones. Although it is challenging to attribute individual cyclones to carbon emissions, scientific studies indicate that the overall increase in carbon dioxide levels is contributing to a greater number of severe cyclones in specific regions. In addition, the impact of cyclones can be exacerbated by rising sea levels associated with global warming and carbon emissions. Higher sea levels result in an increased storm surge, which is the abnormal rise in water level during a cyclone. This storm surge can cause devastating flooding in coastal areas, resulting in significant infrastructure damage and loss of life. To conclude, the prevalence of cyclones is profoundly affected by carbon emissions. The increased atmospheric carbon dioxide levels result in warmer ocean temperatures, creating a more favorable environment for cyclone formation and intensification. Changes in climate patterns caused by carbon emissions also impact the frequency and track of cyclones. Furthermore, the rising sea levels associated with global warming can worsen the impact of cyclones through increased storm surge. It is crucial for society to address carbon emissions and work towards sustainable solutions in order to mitigate the impacts of cyclones and other severe weather events.

- Q: Carbon steel with carbon steel, carbon steel yuan yuan is the same? The trouble to know the answer urgently

- Nor can we see carbon steel and carbon circle are called carbon circle. If the carbon steel and carbon circle are called carbon that are circular steel.

Send your message to us

Injection Carbon FC90-95 with Good and Stable Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches