Carbon Fiber 1200

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2Ton m.t.

- Supply Capability:

- 1000Ton m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

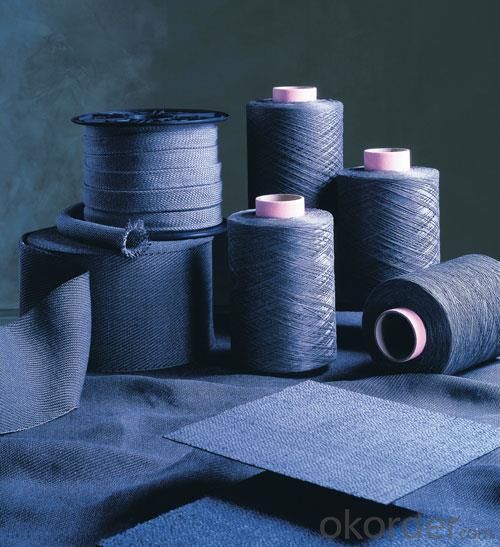

Specifications of Carbon Fiber 1200

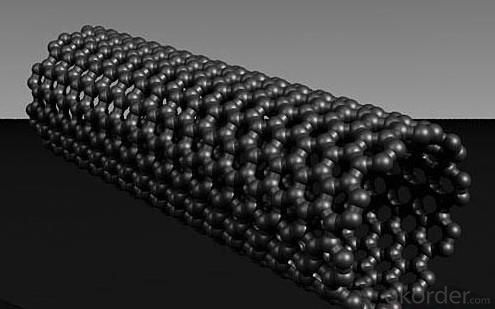

1. Material: carbonized polyacrylonitrile fiber

2. Filament number:6k

3. Fiber type: T700

4. Tensile strength: 360kgf/mm2

General Data of Carbon Fiber 1200

|

Tow Size |

Tow Count/CM |

Weave Style |

WidthRange (mm) |

Std. Width (mm) |

Thickness (mm) |

FAW (g/sq.m) |

FAW (oz/sq.yd) |

|

3K |

4 x 4 |

Plain |

10~1500 |

1000 |

0.16 |

160 |

4.72 |

|

3K |

4 x 4 |

2x2 Twill |

10~1500 |

1000 |

0.16 |

160 |

4.72 |

|

3K |

5 x 4 |

Plain |

10~1500 |

1000 |

0.18 |

180 |

5.31 |

|

3K |

5 x 4 |

2x2 Twill |

10~1500 |

1000 |

0.18 |

180 |

5.31 |

|

3K |

5 x 5 |

Plain |

10~1500 |

1000 |

0.2 |

200 |

5.90 |

|

3K |

5 x 5 |

2x2 Twill |

10~1500 |

1000 |

0.2 |

200 |

5.90 |

|

3K |

5 x 6 |

Plain |

10~1500 |

1000 |

0.22 |

220 |

6.49 |

|

3K |

5 x 6 |

2x2 Twill |

10~1500 |

1000 |

0.22 |

220 |

6.49 |

|

3K |

6 x 6 |

Plain |

10~1500 |

1000 |

0.24 |

240 |

7.08 |

|

3K |

6 x 6 |

2x2 Twill |

10~1500 |

1000 |

0.24 |

240 |

7.08 |

|

3K |

8 x 8 |

Plain |

10~1500 |

1000 |

0.32 |

320 |

9.44 |

|

3K |

8 x 8 |

2x2 Twill |

10~1500 |

1000 |

0.32 |

320 |

9.44 |

|

3K |

8 x 8 |

8H Satin |

10~1500 |

1000 |

0.32 |

320 |

9.44 |

Storage of Carbon Fiber 1200

It is recommended that the carbon fiber fabric are stored in a cool and dry environment. Recommended temperature range of storage is between 10 ~ 30 degree and relative humidity between 50 ~ 75%.The carbon fiber fabric should remain in the packaging until just prior to use.

Packaging & Delivery of Carbon Fiber 1200

Product is manufactured in form of a roll wound on a paper tube and then packed in a plastic film and placed within a cardboard carton. Rolls can be loaded into a container directly or on pallets.

Packaging Detail: carton

Delivery Detail: within 20 days

- Q: How does carbon form?speed

- How is coal formed?Coal is known as black gold, the food industry, it is one of the main energy use of the human world since eighteenth Century. Although its important position has been replaced by oil, but in the future for a long period of time, due to the exhaustion of petroleum, inevitable decline, but because of the huge reserves of coal, and the rapid development of science and technology, the new technology of coal gasification is becoming more mature and widely used, coal will become one of the production and life of human beings in an irreplaceable energy.Coal is millions of years of plant leaves and roots, stacked on the ground with a layer of very thick black humus, due to changes in the earth's crust constantly buried underground, long isolated from the air and under high temperature and pressure, after a series of complex physical and chemical changes and other factors, the formation of black however, this fossil, is the coal forming process.The thickness of coal seam in a coal mine and the crust drop speed and accumulation amount of plant remains. The crust decreased rapidly, the plant remains piled thick, the coal seam is thick, on the other hand, the crust decline slowly, the accumulation of plant remains thin, the mine coal seam is thin. The tectonic movement of the crust to the original level of coal seam folds and faults occur, some underground coal seam buried deeper, and squeezed to the surface, even above the ground, more likely to be found. There are some relatively thin coal seam, and the area is not large, so there is no value related to the formation of coal mining, so far not find the update statement.

- Q: How is carbon used in the electronics industry?

- Carbon is used in the electronics industry in various ways. One of the most common uses of carbon in electronics is as a key component in the production of carbon-based materials such as carbon nanotubes and graphene. These materials have unique properties that make them ideal for use in electronic devices. Carbon nanotubes, for example, are cylindrical structures made of carbon atoms arranged in a tube-like manner. They possess excellent electrical conductivity, thermal conductivity, and mechanical strength. These properties make them useful in various electronic applications such as transistors, sensors, and batteries. Carbon nanotubes can be used to create smaller and more efficient electronic components, leading to the development of smaller, faster, and more powerful electronic devices. Graphene, on the other hand, is a single layer of carbon atoms arranged in a two-dimensional lattice. It is an excellent conductor of electricity and heat, and it also has remarkable mechanical strength. These properties make graphene suitable for applications such as flexible displays, touchscreens, and energy storage devices. Graphene-based electronics have the potential to revolutionize the industry by enabling flexible and transparent devices that can be integrated into various surfaces and objects. Carbon is also utilized in the production of carbon-based resistors and electrodes. Carbon resistors are widely used in electronic circuits to control the flow of current. They provide a stable and predictable resistance, ensuring the proper functioning of electronic devices. Carbon electrodes, on the other hand, are used in batteries, fuel cells, and capacitors to facilitate the flow of electrical charge. Furthermore, carbon is crucial in the manufacturing of printed circuit boards (PCBs). PCBs are essential components in electronic devices as they provide a platform for interconnecting various electronic components. Carbon is used as a conductive ink in the fabrication of PCBs, allowing for the creation of intricate circuit patterns. In summary, carbon plays a vital role in the electronics industry. Its unique properties enable the development of advanced materials and components that enhance the performance and functionality of electronic devices. From carbon nanotubes and graphene to resistors and electrodes, carbon-based materials are shaping the future of electronics by enabling smaller, faster, and more efficient devices.

- Q: What are the impacts of carbon emissions on marine life?

- Carbon emissions, particularly in the form of carbon dioxide (CO2) released from burning fossil fuels, have significant impacts on marine life. One of the primary effects is ocean acidification, which occurs when excess CO2 is absorbed by seawater, leading to a decrease in pH levels. This acidification can have detrimental effects on marine organisms, especially those with calcium carbonate shells or skeletons, such as corals, mollusks, and some plankton. As the pH levels decrease, it becomes harder for these organisms to build and maintain their shells. This can result in reduced growth rates, weakened shells, and increased vulnerability to predation and disease. Additionally, the dissolution of calcium carbonate shells due to ocean acidification can disrupt the entire food chain, as many organisms rely on these shells for protection or as a food source. Furthermore, carbon emissions contribute to global warming, leading to rising sea temperatures. Warmer waters can cause coral bleaching, a phenomenon where corals expel the colorful algae living within their tissues, resulting in the loss of their main food source and leading to their eventual death. Coral reefs are vital ecosystems that support a diverse array of marine life, and their decline has far-reaching consequences on biodiversity and coastal communities that rely on them for tourism and fisheries. The impacts of carbon emissions on marine life extend beyond individual species and ecosystems. Climate change, driven by carbon emissions, can disrupt ocean currents, alter weather patterns, and cause changes in nutrient availability. These changes can affect the distribution and abundance of marine organisms, leading to shifts in species composition and potential loss of biodiversity. It is worth noting that the impacts of carbon emissions on marine life are interconnected with other stressors such as overfishing, pollution, and habitat destruction. These combined pressures exacerbate the vulnerability of marine ecosystems and increase the risks of irreversible damage. To mitigate the impacts of carbon emissions on marine life, reducing greenhouse gas emissions is crucial. Transitioning to cleaner and renewable energy sources, improving energy efficiency, and adopting sustainable practices can help slow down the rate of ocean acidification and global warming. Additionally, protecting and restoring marine habitats, implementing sustainable fishing practices, and reducing pollution can enhance the resilience of marine ecosystems and promote the recovery of marine life.

- Q: I want to know why the ATP in the five carbon sugar is a DNA RNA??

- ATP (adenosine-triphosphate) Chinese name three phosphate adenosine, also called ATP (adenosine three phosphate), referred to as ATP, which A said adenosine, T said the number is three, P said that the phosphate group, connecting three phosphate groups. An adenosine ribose adenine nucleoside by connection formation.If it is deoxyribonucleic acid, it is called three phosphate adenine nucleoside, or dATP

- Q: What are the effects of carbon emissions on the stability of mountains?

- Carbon emissions have a significant impact on the stability of mountains. One of the main effects is the accelerated melting of glaciers and ice caps due to global warming caused by carbon emissions. As temperatures rise, the ice and snow that hold mountains together begin to melt, leading to increased instability. This melting can lead to more frequent and larger avalanches, landslides, and rockfalls, posing a significant threat to human settlements and ecosystems in mountainous areas. Another effect of carbon emissions on mountain stability is the alteration of precipitation patterns. As the climate changes, rainfall becomes more unpredictable, resulting in a higher frequency of intense rainfall events. This increased rainfall can cause soil erosion and weaken the stability of mountain slopes. The combination of increased erosion and weakened slopes can lead to landslides and other mass movements, further destabilizing mountains. Furthermore, carbon emissions contribute to the acidification of rainwater, which can have detrimental effects on the stability of mountains. Acid rain can erode rocks and soil, making them more susceptible to weathering processes. This weakening of the geological structure can increase the likelihood of landslides and rockfalls. Lastly, the impact of carbon emissions on mountain stability extends beyond physical changes. Climate change resulting from carbon emissions can also lead to shifts in ecosystems and biodiversity in mountainous regions. These changes can affect the stability and resilience of mountain ecosystems, as well as alter the patterns of vegetation cover. The loss of vegetation cover, for example, can further increase the susceptibility of slopes to erosion and landslides. In summary, carbon emissions have numerous adverse effects on the stability of mountains. From accelerated melting of glaciers to altered precipitation patterns, acid rain, and shifts in ecosystems, these emissions pose a significant threat to the geological and ecological stability of mountains. It is crucial to reduce carbon emissions and address climate change to mitigate these effects and preserve the stability of mountain regions.

- Q: How does carbon affect the ozone layer?

- Carbon does not directly affect the ozone layer. However, certain carbon compounds, such as chlorofluorocarbons (CFCs), can release chlorine atoms when they reach the stratosphere. These chlorine atoms can then react with ozone molecules, leading to the depletion of the ozone layer.

- Q: How is carbon dioxide formed?

- Carbon dioxide is formed through various natural and man-made processes. One of the primary sources of carbon dioxide is the combustion of fossil fuels such as coal, oil, and natural gas. When these fuels are burned for energy production or transportation, carbon in the form of hydrocarbons combines with oxygen from the air, resulting in the formation of carbon dioxide. Additionally, carbon dioxide is released during natural processes like volcanic eruptions and respiration by living organisms. During volcanic eruptions, molten rock releases carbon dioxide gas, which is then released into the atmosphere. Similarly, living organisms including humans, animals, and plants produce carbon dioxide as a byproduct of respiration, where oxygen is taken in and carbon dioxide is expelled. Deforestation and land-use changes also contribute to the formation of carbon dioxide. Trees and plants absorb carbon dioxide as part of photosynthesis, but when forests are cleared, this natural carbon sink is lost, leading to an increase in atmospheric carbon dioxide levels. Lastly, industrial processes such as cement production and chemical reactions in manufacturing also release carbon dioxide into the atmosphere. These processes involve the breakdown or burning of carbon-containing compounds, resulting in the release of carbon dioxide as a waste product. Overall, carbon dioxide is formed through a combination of natural processes and human activities, with the burning of fossil fuels being the largest contributor to its increased levels in the atmosphere.

- Q: How is carbon used in the production of paints?

- Carbon is used in the production of paints as a pigment or coloring agent. Carbon black, which is made from the incomplete combustion of petroleum products, is commonly used to provide a deep black color to paints. It is also used in the form of graphite to create black or gray shades. Additionally, carbon-based materials like activated charcoal are used as fillers or extenders in certain types of paints.

- Q: How does carbon affect the acidity of oceans?

- Carbon dioxide (CO2) dissolves in seawater to form carbonic acid (H2CO3), which increases the concentration of hydrogen ions (H+) in the water, leading to ocean acidification. This decrease in pH affects marine life by hindering the ability of shell-forming organisms to build and maintain their shells, as well as impacting other vital biological processes.

- Q: What is the difference between carbon nanomaterials and nano carbon materials?

- Carbon nanomaterials are carbon materials with at least one dimension less than 100nm in dispersed phase scale. The dispersed phase can be composed of either carbon atoms or heterogeneous atoms (non carbon atoms), or even nanopores.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 20,000 |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9002:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 20% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Carbon Fiber 1200

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2Ton m.t.

- Supply Capability:

- 1000Ton m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords