Low Sulphur Calcined Petroleum Coke S 0.7

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 11 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Calcined Petroleum Coke Description

Calcined Petroleum Coke is made from raw petroleum coke,which is calcined in furnace at a high temperature(1200-1300℃).CPC/Calcined Petroleum Coke is widely used in steelmaking,castings manufacture and other metallurgical industry as a kind of recarburizer because of its high fixed carbon content,low sulfur content and high absorb rate.Besides,it is also a best kind of raw materials for producing artifical graphite(GPC/Graphitized Petroleum Coke) under the graphitizing temperature(2800℃).

2.Main Features of the Calcined Petroleum Coke

High-purity graphitized petroleum coke is made from high quality petroleum coke under a temperature of 2,500-3,500°C. As a high-purity carbon material, it has characteristics of high fixed carbon content, low sulfur, low ash, low porosity etc.It can be used as carbon raiser (Recarburizer) to produce high quality steel,cast iron and alloy.It can also be used in plastic and rubber as an additive.

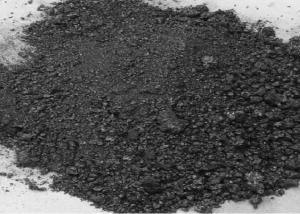

3. Calcined Petroleum Coke Images

4. Calcined Petroleum Coke Specification

PARAMETER UNIT GUARANTEE VALUE | ||

F.C.% | 98.5MIN | 98.5% MIN |

ASH % | 0.5 MAX | 0.8MAX |

V.M.% | 0.7 MAX | 0.7 MAX |

SULFUR % | 0.5 MAX | 0.7 MAX |

MOISTURE % | 0.5MAX | 0.5MAX |

SIZE | 0-5MM OR AS REQUEST | |

5.FAQ of Calcined Petroleum Coke

1). Q: Are you a factory or trading company?

A: We are a factory.

2). Q: Where is your factory located? How can I visit there?

A: Our factory is located in ShanXi, HeNan, China. You are warmly welcomed to visit us!

3). Q: How can I get some samples?

A: Please connect me for samples

4). Q: Can the price be cheaper?

A: Of course, you will be offered a good discount for big amount.

PARAMETER UNIT GUARANTEE VALUE | ||

F.C.% | 98.5MIN | 98.5% MIN |

ASH % | 0.5 MAX | 0.8MAX |

V.M.% | 0.7 MAX | 0.7 MAX |

SULFUR % | 0.5 MAX | 0.7 MAX |

MOISTURE % | 0.5MAX | 0.5MAX |

SIZE | 0-5MM OR AS REQUEST | |

- Q: How does a kebab cook at home?

- Do you have long fire sticks in your house?...... Yes, just a carbon and burn it over the gas stove...... If not, apply a little oil underneath......Burn, put carbon on the top, pay attention to leave the gap, do not suppress it.

- Q: Intend to go to the barbecue and 35 friends over the weekend, but because it is new, so I don't know how to put the carbon burning, found some web sites are also a few pens, see me confused......Hope which experienced friend to help enlighten me, the best to the specific point, thank you ah!

- I see selling mutton string is usually used in newspapers or put a small wood charcoal stove, just like

- Q: What is carbon neutral certification?

- Carbon neutral certification is a process by which an organization, product, or service is evaluated and verified to have a net-zero carbon footprint. This means that the entity in question has taken significant measures to reduce its greenhouse gas emissions and has offset the remaining emissions through the purchase of carbon credits or investments in projects that mitigate or remove carbon dioxide from the atmosphere. To achieve carbon neutrality, the organization or product undergoes a rigorous assessment that includes measuring its carbon emissions, setting reduction targets, implementing initiatives to reduce its carbon footprint, and tracking progress. Once the emissions have been reduced as much as possible, any remaining emissions are offset by investing in verified projects such as reforestation, renewable energy, or energy efficiency projects that remove or reduce greenhouse gases from the atmosphere. The certification process is typically carried out by an independent third-party organization that evaluates and verifies the organization's carbon neutrality claims. This ensures transparency and credibility in the certification process. Once certified, the organization or product can use the carbon neutral label to demonstrate its commitment to environmental sustainability and responsible carbon management. Carbon neutral certification is important as it provides a standardized and recognized way for organizations and products to demonstrate their commitment to combating climate change. It allows consumers and stakeholders to make informed choices by supporting entities that have taken concrete steps to reduce their carbon emissions and contribute to a more sustainable future. Additionally, carbon neutral certification encourages organizations to adopt sustainable practices and invest in projects that have a positive environmental impact, thereby accelerating the transition to a low-carbon economy.

- Q: How do forests act as carbon sinks?

- Forests act as carbon sinks by absorbing carbon dioxide from the atmosphere through the process of photosynthesis. Trees and other plants take in carbon dioxide and convert it into oxygen, while storing the carbon in their trunks, branches, and roots. This stored carbon remains in the forest ecosystem, reducing the amount of greenhouse gases in the atmosphere and helping to mitigate climate change.

- Q: What are the consequences of increased carbon emissions on economic stability?

- Economic stability is significantly impacted by the increase in carbon emissions. Climate change worsens as a result, resulting in more frequent and severe natural disasters like hurricanes, floods, and wildfires. These events cause immense economic damage, including infrastructure destruction, property loss, and supply chain disruption. Moreover, the economic implications of climate change, driven by the rise in carbon emissions, are long-term. Coastal cities and industries are threatened by rising sea levels, leading to potential population displacement and valuable asset loss. Agricultural productivity is affected by extreme heatwaves and droughts, impacting food security and causing price increases. These climate-related disruptions can destabilize economies, especially in vulnerable regions highly dependent on agriculture or tourism. Furthermore, substantial financial investments are required for climate change mitigation and adaptation efforts, such as transitioning to cleaner energy sources and implementing climate policies. This strains government budgets and diverts resources from other socio-economic priorities, potentially resulting in reduced funding for education, healthcare, and infrastructure development. Additionally, increased carbon emissions have economic consequences beyond immediate climate-related impacts. The reliance on fossil fuels as the primary energy source contributes to volatile oil prices, which can disrupt global markets and affect economic stability. As the world moves towards a low-carbon economy, industries heavily reliant on fossil fuels may face significant challenges, leading to job losses and economic upheaval. To summarize, the increase in carbon emissions has extensive effects on economic stability. Climate change causes more frequent and severe natural disasters, resulting in significant economic damage. Responding to climate change through mitigation and adaptation efforts strains government budgets and diverts resources from other critical sectors. Moreover, the reliance on fossil fuels poses long-term risks to industries tied to these resources. It is essential to address carbon emissions to safeguard economic stability and foster sustainable growth.

- Q: What are the consequences of increased carbon emissions on educational systems?

- Increased carbon emissions have profound consequences on educational systems. One of the major consequences is the negative impact on the health and well-being of students and teachers. Carbon emissions contribute to air pollution, which can lead to respiratory problems, allergies, and other health issues. This, in turn, affects attendance rates and overall student performance. Furthermore, the effects of climate change caused by carbon emissions, such as extreme weather events and rising temperatures, can disrupt educational infrastructure. Schools may be closed or damaged due to hurricanes, floods, or heatwaves, leading to a loss of instructional time and disruption to the learning environment. In addition, increased carbon emissions contribute to the depletion of natural resources, such as water and food, which can have severe consequences for educational systems. In regions heavily reliant on agriculture, climate change can disrupt food production and availability, leading to malnutrition and reduced cognitive development in children. Lack of access to clean water can also impact sanitation in schools, increasing the risk of diseases and impacting students' ability to concentrate and learn. Moreover, the consequences of increased carbon emissions extend beyond physical health and infrastructure. Climate change is a complex global issue that requires an understanding of scientific concepts and critical thinking skills to address. However, inadequate education on climate change and its causes can hinder students' ability to comprehend and respond to this pressing issue. Furthermore, the economic impacts of climate change resulting from increased carbon emissions can strain educational systems. Governments may have to divert resources away from education to address climate-related disasters and their aftermath. Limited funding for education can lead to reduced access to quality education, inadequate facilities, and lower teacher salaries, all of which can negatively impact the overall quality of education provided. In conclusion, increased carbon emissions have wide-ranging consequences on educational systems. From the health and well-being of students and teachers to disruptions in infrastructure and access to resources, the effects of carbon emissions can hinder educational outcomes. Addressing climate change and reducing carbon emissions is crucial not just for the environment but also for the future of education.

- Q: What are the consequences of increased carbon emissions on social inequality?

- Increased carbon emissions have significant consequences on social inequality. Firstly, the impacts of climate change, driven by carbon emissions, disproportionately affect marginalized communities who often lack the resources and infrastructure to adapt or recover from extreme weather events, such as floods, droughts, and storms. This exacerbates existing inequalities and widens the gap between the rich and the poor. Secondly, the burning of fossil fuels, a major contributor to carbon emissions, disproportionately affects low-income communities who are more likely to live near industrial areas or power plants. This exposure to air pollution leads to higher rates of respiratory diseases and other health issues, further deepening social inequality as access to quality healthcare is often limited for these communities. Moreover, the consequences of climate change, such as agricultural disruptions, water scarcity, and increased food prices, can lead to social unrest, migration, and conflicts, disproportionately impacting vulnerable populations. This creates a ripple effect on social and economic stability, further marginalizing already disadvantaged groups. Addressing carbon emissions and mitigating climate change is crucial for reducing social inequality. Transitioning to renewable energy sources, investing in sustainable infrastructure, and implementing policies that prioritize the needs of marginalized communities can help alleviate the burden on those most affected and promote a more equitable society.

- Q: How accurate is carbon dating?

- Carbon dating is generally considered to be a highly accurate method for determining the age of organic materials up to around 50,000 years old. However, it becomes less precise for older samples due to the decreasing amount of carbon-14 remaining. Additionally, certain factors such as contamination and environmental variations can affect the accuracy of the results.

- Q: Stability, primary carbon, two carbon, three carbon, four carbon

- In hydrocarbon molecules, with 3 hydrogen atoms of carbon atoms is called the first carbon atom (also called a carbon atom or primary carbon atom); with 2 hydrogen atoms of the carbon atoms is called second carbon atom (also called the two carbon atoms or secondary carbon atoms); with 1 hydrogen atoms of the carbon atoms is called third carbon atoms (also called the three carbon atom or tertiary carbon atoms)

- Q: How does carbon impact the energy balance of the Earth?

- The energy balance of the Earth is primarily influenced by carbon, which plays a significant role in the greenhouse effect. Carbon dioxide, a greenhouse gas, is emitted into the atmosphere through both natural processes and human activities such as the burning of fossil fuels and deforestation. The greenhouse effect occurs naturally when specific gases in the atmosphere trap heat from the sun, preventing it from escaping back into space. This process is essential for maintaining a suitable temperature for life on Earth. However, excessive carbon emissions have intensified the greenhouse effect, resulting in global warming and climate change. When carbon dioxide and other greenhouse gases accumulate in the atmosphere, they trap more heat, causing the Earth's surface temperature to rise. This temperature increase disrupts the planet's energy balance, leading to the melting of polar ice caps, rising sea levels, and more frequent and severe extreme weather events. Moreover, carbon alters the energy balance of the Earth by impacting the carbon cycle. The carbon cycle is a natural process in which carbon is exchanged between the atmosphere, oceans, and land. However, human activities have significantly disrupted this cycle by releasing large quantities of carbon into the atmosphere, primarily through the combustion of fossil fuels. Excessive carbon emissions create an imbalance in the carbon cycle, as the natural processes that absorb and store carbon, such as photosynthesis and the ocean's ability to absorb CO2, cannot keep up with the rate of emissions. This leads to an accumulation of carbon dioxide in the atmosphere, further intensifying the greenhouse effect and contributing to global warming. In conclusion, carbon has a significant impact on the energy balance of the Earth by intensifying the greenhouse effect and disrupting the natural carbon cycle. It is crucial to reduce carbon emissions and transition to cleaner and more sustainable energy sources in order to mitigate the adverse effects of carbon on the planet's energy balance. Ultimately, this is necessary to preserve the health and stability of our environment.

Send your message to us

Low Sulphur Calcined Petroleum Coke S 0.7

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 11 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords