CPC Low Sulfur Petroleum Coke Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Model Number: carbon 95%

Application: steel making

fix carbon content: 95%min

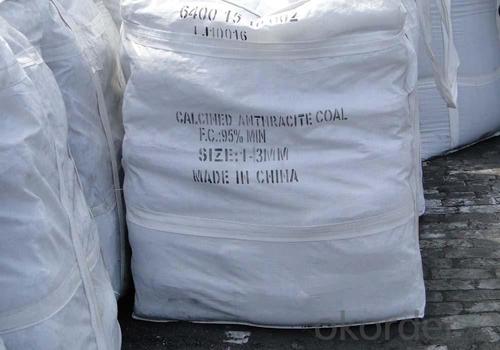

Packaging & Delivery

| Packaging Details: | Standard export packing 1.in one Ton bag 2.P.P. woven bag(25Kg) laminated with kraft paper inside 3.40bags x 25kg per one(1) metric ton bag 4.Other packing available on request |

|---|---|

| Delivery Detail: | ASAP |

Specifications

CPC Low Sulfur Petroleum Coke Best Price

Petroleum coke products can be divided into needle coke, sponge coke, projectile coke and coke breeze four kinds.

Calcined Petroleum Coke

F.C.: 98.5%MIN

ASH: 0.8% MAX

V.M.: 0.7%MAX

S:0.5%MAX

Moisture: 0.5%MAX

Structure

CPC Low Sulfur Petroleum Coke Best Price

Shape: granule

Dimensions: 0-1mm, 1-5mm, 1-6mm, 2-8mm, etc

Product Type: Carbon Additive

C Content (%): 98-99.5% MIN

Working Temperature: -

S Content (%): 0.5%-0.7%MAX

Ash Content (%): 0.7%MAX

Volatile:0.8%MAX

Moisture: 0.5% MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

Feature

CPC Low Sulfur Petroleum Coke Best Price

Physics and chemistry performance :

Unit | Index | |||||

No.1 | No.2 | No.3 | ||||

Density | g/cm3 | 2.04 | 2.00 | 2.00 | ||

sulphur content | %≤ | 0.5 | 1.0 | 2.5 | ||

volatility | %≤ | 0.5 | 0.5 | 0.5 | ||

ash content | %≤ | 0.5 | 0.5 | 0.5 | ||

moisture | %≤ | 0.3 | 0.5 | 0.5 | ||

charcoal | %≤ | 98.5 | 98.0 | 98.0 | ||

Image

CPC Low Sulfur Petroleum Coke Best Price

FAQ:

CPC Low Sulfur Petroleum Coke Best Price

How to classify calcined petroleum coke?

1) According to difference of sulfur content, can be divided into high sulfur coke (sulfur content more than 4%), sulphur in coke sulfur content (2% 4%) and low sulfur coke (sulfur content below 2%).

2) Petroleum coke products can be divided into needle coke, sponge coke, projectile coke and coke breeze four kinds:

3) Needle coke, has obvious needle-like structure and fiber texture, mainly used for steel-making in high power and ultra-high power graphite electrode. As a result of needle coke in sulfur content, ash content, volatile matter and true density and so on have strict quality requirements, so the production process of needle coke and raw materials have special requirements.

4) The sponge coke, high chemical reactivity, low content of impurities, mainly used in the aluminum industry and carbon industry.

5) Focal or spherical coke: the projectile shape is round, diameter 0.6-30 mm, usually from the production of high sulphur, high asphaltic residual oil, can only be used as industrial fuel power generation, cement etc.

6) Coke breeze: fluidized coking process, the fine particles (0.1- 0.4 mm) in diameter, high volatile, high expansion coefficient, cannot be directly used for electrode preparation and carbon industry.

Advantage:

CPC Low Sulfur Petroleum Coke Best Price

1. High quality and competitive price.

2. Timely delivery.

3. If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q: Are carbon fibers organic polymer materials?

- No, carbon fiber is not an organic polymer material, and carbon fiber is an inorganic polymer materialOrganic polymer compounds referred to as polymer compound or polymer, also known as polymer is composed of one or several structural units repeatedly (103~105) compound repeat connected. Their elements are not many, mainly carbon, hydrogen, oxygen and nitrogen, but the molecular weight is large, generally above 10000, high millions.

- Q: What is carbon nanosensor?

- A carbon nanosensor is a type of sensor that utilizes carbon-based materials at the nanoscale to detect and measure various substances or physical properties. These sensors are extremely small and have a high sensitivity, allowing them to detect even minute amounts of target molecules or changes in their environment. Carbon nanosensors can be engineered to target specific molecules or properties by functionalizing the surface of the carbon nanomaterials with specific receptors or probes. Additionally, carbon nanosensors can be integrated with other technologies, such as electronics, to enable real-time monitoring and data analysis. The unique properties of carbon nanomaterials, such as their high surface area, electrical conductivity, and chemical stability, make them ideal for constructing sensitive and versatile sensors in a wide range of applications, including environmental monitoring, medical diagnostics, and food safety.

- Q: What are the different allotropes of carbon?

- Carbon has several allotropes, each possessing unique physical and chemical properties. The most renowned allotrope is diamond, renowned for its hardness and brilliance. Diamond consists of carbon atoms arranged in a three-dimensional structure, with each atom bonded to four neighboring carbon atoms in a tetrahedral pattern. Graphite is another carbon allotrope, known for its softness and ability to conduct electricity. Carbon atoms in graphite are arranged in layers that are held together by weak forces, allowing easy sliding between layers. This layered arrangement grants graphite its lubricating properties. Fullerenes, a distinct class of carbon allotropes, are composed of carbon atoms arranged in closed cage-like structures. The most famous fullerene is buckminsterfullerene (C60), made up of 60 carbon atoms bonded together to form a hollow sphere resembling a soccer ball. Fullerenes exhibit unique properties such as high tensile strength and superconductivity. Carbon nanotubes, cylindrical structures made from rolled-up graphene sheets, are yet another carbon allotrope. The arrangement of carbon atoms determines the structure and properties of carbon nanotubes. They are recognized for their exceptional strength, electrical conductivity, and thermal conductivity. Amorphous carbon, lacking a definite crystal structure, is another carbon allotrope. It is commonly found in substances like soot, coal, and charcoal. Amorphous carbon can possess a wide range of properties based on its structure, varying from soft and powdery to hard and brittle. These examples highlight the diverse allotropes of carbon. Carbon's ability to form various allotropes with distinct properties contributes to its significance in numerous applications, including jewelry, electronics, and material science.

- Q: What are the consequences of increased carbon emissions on urban areas?

- Increased carbon emissions have numerous consequences on urban areas. Firstly, it leads to a rise in air pollution, contributing to respiratory issues and increased health risks for the population. Additionally, carbon emissions contribute to the greenhouse effect, leading to higher temperatures and exacerbating the urban heat island effect, which can result in discomfort, heat-related illnesses, and increased energy demands for cooling. Moreover, increased carbon emissions contribute to climate change, leading to more frequent and intense extreme weather events like storms and heatwaves, which pose significant threats to urban infrastructure, public safety, and economic stability. Overall, the consequences of increased carbon emissions on urban areas are detrimental to both the environment and human well-being.

- Q: How does carbon affect the formation of air pollution in urban areas?

- Carbon does not directly affect the formation of air pollution in urban areas. However, carbon-based pollutants, such as carbon monoxide and carbon dioxide, which are released from the burning of fossil fuels, contribute significantly to air pollution in urban areas.

- Q: How can individuals reduce their carbon footprint?

- Individuals can reduce their carbon footprint by adopting sustainable lifestyle choices such as conserving energy, using public transportation or carpooling, eating a plant-based diet, reducing waste, and supporting renewable energy sources. Additionally, individuals can also make a difference by planting trees, supporting eco-friendly products, and spreading awareness about climate change.

- Q: What are fossil fuels and how are they formed?

- Fossil fuels are natural energy resources derived from the remains of ancient plants and animals that lived millions of years ago. They are formed through a long process involving the decomposition and conversion of organic matter under high pressure and temperature over geological time. This transformation results in the formation of coal, oil, and natural gas, which are the primary types of fossil fuels.

- Q: What is the difference between soil organic matter and soil organic carbon?

- Organic matter is organic matter, but a large part of which is composed of carbon, but carbon content of different organic matter is different, the conversion coefficient is 1.724, most of the organic matter and organic carbon conversion of a mean value is the value. Usually we measured is organic carbon, and then multiplied by 1.724 is organic matter.

- Q: How does deforestation contribute to carbon emissions?

- Deforestation contributes to carbon emissions by releasing large amounts of stored carbon dioxide (CO2) into the atmosphere. Trees act as carbon sinks, absorbing CO2 from the air during photosynthesis and storing it in their biomass. When forests are cleared or burned, this stored CO2 is released back into the atmosphere, adding to greenhouse gas levels and contributing to climate change.

- Q: How can carbon be stored underground?

- Carbon capture and storage (CCS) is a process that allows for the underground storage of carbon. This process involves the capture of carbon dioxide (CO2) emissions from industrial sources, such as power plants or cement factories, followed by the storage of the captured CO2 deep underground in geological formations. To begin, the CO2 emissions are captured before they are released into the atmosphere. Various technologies, such as post-combustion capture, pre-combustion capture, and oxy-fuel combustion, are available for this purpose. These technologies separate the CO2 from other gases, like nitrogen, resulting in a concentrated stream of CO2 that is easy to store. Once the CO2 is captured, it must be transported to a suitable storage site. Depending on the distance and location of the storage site, transportation can be done through pipelines or ships. The CO2 is then injected deep underground into geological formations, including depleted oil and gas reservoirs, saline aquifers, or coal seams. The selection of storage sites is done carefully, taking into consideration their ability to safely and permanently store the CO2. The chosen geological formations must have an impermeable rock layer, known as a caprock, to prevent CO2 leakage to the surface. Regular monitoring of the storage sites ensures that the stored CO2 remains securely underground. The storage of carbon underground has significant benefits in reducing CO2 emissions and addressing climate change. It effectively prevents the release of CO2 into the atmosphere, where it contributes to the greenhouse effect and global warming. Additionally, CCS can be combined with enhanced oil recovery (EOR) techniques, using the injected CO2 to extract more oil from depleted reservoirs, making the process economically viable. However, it is important to note that carbon storage is not a permanent solution to climate change. While it can help in reducing emissions during the transition to cleaner energy sources, it should not replace efforts to decarbonize the economy and reduce dependence on fossil fuels. Moreover, the long-term safety and environmental impacts of underground carbon storage need thorough examination to ensure its effectiveness and sustainability.

Send your message to us

CPC Low Sulfur Petroleum Coke Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords