IEC STANDARD BARE COPPER STRANDED CONDUCTOR 25MM2

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: BCC 25MM2

Type: High Voltage

Application: Power Station

Conductor Material: Copper

Packaging & Delivery

| Packaging Details: | wooden drum packing |

|---|---|

| Delivery Detail: | 7 days |

Specifications

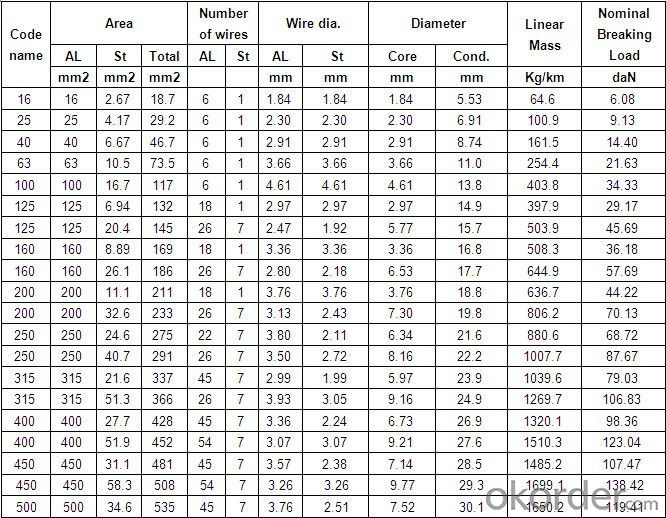

HIGH VOLTAGE BARE COPPER CONDUCTOR CABLE 25MM2

1 GOOD PRICE AND QUALITY

2 SHORT TIME DELIVERY

HIGH VOLTAGE BARE COPPER CONDUCTOR CABLE

APPLICATION

For use on insulators for overhead distribution or for ground conductors

CONSTRUCTION

Soft or annealed, bare or tin coated, solid or concentric stranded copper conductor.

- Q: Currently I have the two wires no ground wire and some two wire with ground outlets (upgrade some time before). Is it allowed in the NEC to run a separate ground wire from one of the two wire with ground outlet to the two wire outlet without changing the old wires?

- It is acceptable to run a separate ground to each box, but like Rusty said, if the wiring to the boxes is BX (flexible metal) or conduit, and the boxes are metallic, then your chances are pretty good that they're already grounded. A GFCI isn't a cure all, and will only work if it has it's own ground. It must also be properly wired to protect downstream outlets.

- Q: I am wiring a cd player in my truck is it necessary to get a wire harness that is made for the year make and model of my truck or can I just cut the factory terminals off and just connect the like colors?

- While a wiring harness isn't strictly necessary, It's highly recommended. The wiring color code on an aftermarket head unit will match up properly with a vehicle-specific wiring harness. The wire colors of your vehicle wiring will NOT be the same as the wire colors on your aftermarket unit. You have to match the wires up according to function, not according to color.

- Q: i need to know which wire is which in a 1999 dodge stratus for the cars stereo

- its usually pretty easy if you look online just goodle it red is usually constant power yellow is usually switched power black is usually ground blue is usually for the rem wire the rest are speaker wires or are not used good luck

- Q: I have an immersion heater in my hot water cylinder (UK airing cubbard), but the wiring isn't connected. But, I seem to be missing a small piece or two. The previous lead wire from the timer/switch is stil there and has two wires in it. Does someone have a generic wiring digram showing which wires connect to the thermostat and which wires connect to the heating element? Thanks!

- Immersion Heater Thermostat Wiring Diagram

- Q: the sensor part has 4 wires,(2 white,1 black and 1 red)each light has 1bl.and 1white

- If all else fails read the directions! Please read the directions that came with the motion sensor/outdoor light. They should have a color code in them somewhere that tells you what each color is and what it should be wired too. If you have any doubts hire a licensed qualified electrician to do it for you. You would be much better off if you don't think you are capable of doing it. If you do think you are capable make sure you turn off the breaker in the breaker box. (Not the light switch on the wall)

- Q: The light fitting I bought has 1x Red Wire (A) 1x Green Wire (E) and 1x Blue Wire (N)...

- The green wire is just a ground wire, black is usually the hot wire, that would leave the blue wire as the neutral wire. The white wire in house wiring is the neutral. The two red and one black from your wall is not standard in the USA, but it may be 220 volts. What kind of light fixture are you replacing, is it on a ceiling fan?

- Q: anybody got a diagram or instructions on how to wire an amp wiring kit in a 1999 audi a4

- You dont need Instructions for Car Specific. You just Need to Hook the large Power wire for your amp direct to battery, The large black ground wire to the frame or body, Something metal. And the small Power wire To Switched power. IE, a terminal on the fuse block thats only hot with the key ON. Thats it. Good luck.

- Q: the quot;rite-tempthermostat was ripped from the wall, and the brown wire, and red wires - both not labled are disconnected...where do they connect? please help....rite-temp thermostat model 8050c

- The Green wire generally is fan The red wires are hot to the AC and Heater The yellow wire is AC The white wire is common. Brown may be used for AC instead of red Hook the Green to the G terminal The Red wire to the Rh terminal The brown wire, I believe is Rc terminal White to W OR c (HOW EVER IT'S LABELED) Yellow to Y

- Q: I have a duplex box and want to put two recepticles in it. Each have two connector post on each side. How do I wire this.

- Take the black wire that is coming in to the box and pig tail 2 short pieces of wire (keep the wires the same color throughout as in use black wires to connect to black wires and white wires... )to it using a wire nut. Do the same to the white wire. For the green wire you will need to do the same if it is a plastic box or add 3 wires if it is a metal box. For the black connect 1 each of the pig tails to the brass screw for each receptacle. For the white do the same except go to the silver screws. For the ground 1 wire goes to the green screw on each receptacle and if required 1 goes to the box itself.

- Q: One wire has part of the plastic coating on the end, the other wire does not.

- the lead is the wires showing. lead wire can also mean attaching a wire and feed it through a wall attach other end to the wire and pull it through. Now if you need both ends to have wire showing take a utility knife firmly place wire on block of wood and lightly cut through the caseing. thats the thick wire that en cases the other wires and peal back and then cut it off. then carefully hold blade of utility knife and wire aganst your thumb on a 45 degrees away from you and pull that will strip the plastic off the wires hope that answers your question dave

Send your message to us

IEC STANDARD BARE COPPER STRANDED CONDUCTOR 25MM2

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches