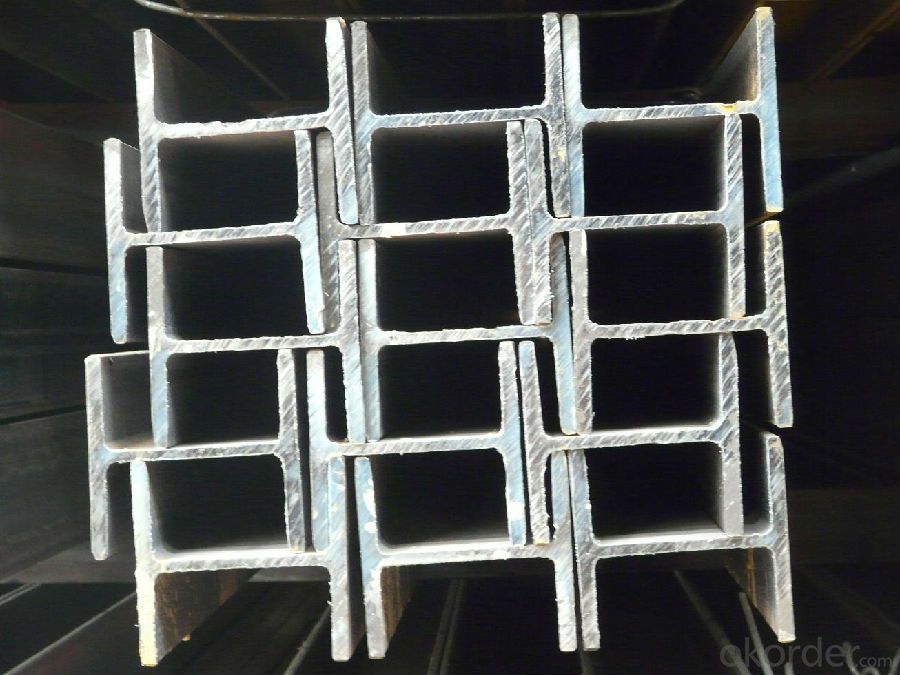

I Beam Prime Hot Rolled IPE IPEAA EN 10025 Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||

a*t | ||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do you package the angle steel when shipping?

A2: All goods are packed in bundles with steel strips and shipped by container or break bulk.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: Can steel I-beams be used for solar panel supports?

- Yes, steel I-beams can be used as supports for solar panels. Steel I-beams are commonly used in construction for their strength and durability, making them suitable for supporting the weight of solar panels. Additionally, steel is resistant to weathering and provides stability, ensuring the panels remain securely mounted.

- Q: What are the different sizes and dimensions of steel I-beams?

- Steel I-beams, also referred to as H-beams or W-beams, are available in various sizes and dimensions to accommodate different construction and engineering needs. The manufacturer and intended use can affect the specific sizes and dimensions of steel I-beams. Nevertheless, there are commonly accessible standard sizes and dimensions. These encompass: 1. Wide Flange: Wide flange I-beams possess a broader flange in comparison to the web's height. Wide flange I-beams can have depths (height) ranging from 4 inches to 44 inches and flange widths ranging from 4.5 inches to 18 inches. The flange thickness and web thickness may also differ. 2. American Standard: Also known as S beams or junior beams, American Standard I-beams feature narrower flanges relative to the web's height. American Standard I-beams can have depths ranging from 3 inches to 24 inches and flange widths ranging from 2.33 inches to 12 inches. The flange thickness and web thickness can also vary. 3. European Standard: European I-beams, also known as HEA, HEB, or HEM beams, adhere to a distinct dimension standard compared to American and wide flange beams. European I-beams are measured in millimeters instead of inches. European standard I-beams can have heights ranging from 80 mm to 1,000 mm and flange widths ranging from 46 mm to 1,000 mm. The flange thickness and web thickness may also differ. It is worth noting that the specific sizes and dimensions of steel I-beams can be influenced by factors such as load-bearing requirements, span length, and structural design considerations. Consulting engineering or construction reference materials, or reaching out to a manufacturer or supplier, can provide more detailed information regarding the sizes and dimensions available for specific applications.

- Q: Channel and I-beam are commonly used in construction sites. It is better to have on-site construction drawings, thank you

- The picture is not good, and the I-beam is generally used for erection of overhanging scaffold. Channel steel, it can be made of steel beams and steel staircase structure, but also can do wall keel

- Q: Can Steel I-Beams be used for mezzanine storage?

- Certainly! Mezzanine storage can indeed utilize steel I-beams. Construction often employs steel I-beams due to their robustness and ability to bear substantial loads. They are well-suited for supporting heavy weights and can endure the mezzanine structure's weight and the stored items. To provide a secure and stable foundation for the mezzanine floor, the I-beams can be firmly bolted or welded into position. Furthermore, steel I-beams can be tailored to meet specific design criteria and easily integrated into existing structures. All in all, steel I-beams are a dependable and effective choice for supporting mezzanine storage systems.

- Q: Are steel I-beams suitable for supporting rooftop swimming pools?

- Yes, steel I-beams are suitable for supporting rooftop swimming pools. Steel I-beams are commonly used in construction for their strength and load-bearing capabilities. They are designed to withstand heavy loads and provide excellent structural support. When it comes to rooftop swimming pools, the weight of the water, pool equipment, and additional features such as decking and furniture can be substantial. Steel I-beams are able to distribute this weight evenly and effectively, ensuring the stability and safety of the rooftop pool. Additionally, steel I-beams are durable, resistant to corrosion, and can be customized to meet specific design requirements. Therefore, they are a reliable and suitable choice for supporting rooftop swimming pools.

- Q: Can steel I-beams be used in underground or tunnel construction?

- Yes, steel I-beams can be used in underground or tunnel construction. Steel I-beams are commonly used in construction due to their strength and durability. In underground or tunnel construction, where the structural integrity is crucial, steel I-beams are often used to support the weight of the structure and provide stability. They can be used as support beams to reinforce the roof, walls, or floor of a tunnel, ensuring that it can withstand the pressure and forces exerted on it. Additionally, steel I-beams can be easily fabricated and customized to fit the specific requirements of the underground or tunnel construction project, making them a versatile and reliable choice.

- Q: What are the different types of steel finishes available for I-beams?

- There are several types of steel finishes available for I-beams, including hot-rolled, cold-rolled, galvanized, and painted finishes.

- Q: Can steel I-beams be painted or coated to match the desired aesthetics?

- Indeed, steel I-beams have the capability to be painted or coated in order to achieve the desired aesthetics. In the realms of construction and industrial applications, steel I-beams are frequently utilized due to their indispensable strength and ability to bear heavy loads. However, the raw steel finish may not always be visually pleasing or suitable for every environment. To achieve the desired aesthetics, there are various methods available for painting or coating steel I-beams. Before commencing with the painting or coating process, it is imperative to properly prepare the surface of the beams to ensure optimal adhesion and durability. This typically involves eliminating any rust, dirt, or contaminants and applying an appropriate primer. Once the surface has been adequately prepared, a diverse range of paint or coating systems can be utilized. Industrial-grade paints, such as epoxy or polyurethane coatings, offer exceptional protection against corrosion and wear. These coatings can also be customized to attain the desired color and finish. Furthermore, powder coating is a widely favored technique for enhancing the aesthetics of steel I-beams. Powder coating involves the application of a dry powder onto the surface of the beams, which is then cured under heat to create a durable and visually appealing finish. Powder coating offers an extensive array of color options and ensures a smooth, uniform appearance. It is crucial to consider the specific requirements of the application when selecting the appropriate paint or coating system. Factors such as environmental conditions, exposure to chemicals or moisture, and the desired level of durability must be taken into account. Seeking guidance from a professional painter or coating specialist can guarantee the best outcome in terms of both aesthetics and performance.

- Q: How do steel I-beams perform in areas with high UV exposure?

- Steel I-beams perform well in areas with high UV exposure due to their protective coatings. The coatings, such as galvanized or painted finishes, are specifically designed to resist the harmful effects of UV rays. These coatings act as a barrier, preventing the steel from direct exposure to the sun's ultraviolet radiation. UV exposure can cause degradation and discoloration of materials over time, but steel I-beams are highly resistant to these effects. The protective coatings not only shield the steel from UV rays but also provide additional corrosion resistance, extending the lifespan of the beams. However, it is important to note that over an extended period, even the most durable coatings may experience some level of degradation. Therefore, regular inspections and maintenance are necessary to ensure the continued performance of steel I-beams in areas with high UV exposure. This may involve periodic reapplication of protective coatings or other maintenance procedures recommended by the manufacturer.

- Q: Can steel I-beams be used in the construction of industrial warehouses?

- Indeed, industrial warehouses can utilize steel I-beams for construction purposes. Steel I-beams are frequently employed in the construction field owing to their robustness and durability. They offer exceptional structural reinforcement and are capable of enduring substantial weights, rendering them exceptionally suitable for industrial settings like warehouses. Furthermore, steel I-beams possess great adaptability and can be readily tailored to fulfill specific design criteria. Additionally, they possess an extended lifespan and necessitate minimal upkeep, making them a financially prudent option for warehouse construction. All in all, steel I-beams are a favored selection for constructing industrial warehouses due to their strength, durability, versatility, and cost-effectiveness.

Send your message to us

I Beam Prime Hot Rolled IPE IPEAA EN 10025 Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords