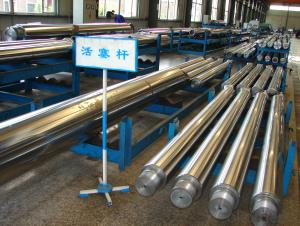

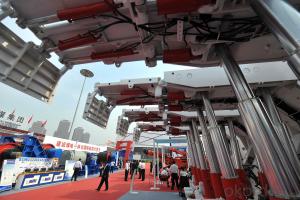

hydraulic ram for excavator heavy duty machinery

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

1.ISO9001:2008

2.Seal:Merkel or Parker

3.Working pressure:16-25Mpa.

4.10 years of experienc

5.Material:CK45

CMAX series engineering hydraulic Cylinder

(1)working pressure:16MPa

(2)Piston diameter: 40-250mm

(3)Seals:Merkel or Parker

(4)Sensor: MTS or Balluff

BOOM,ARM,BUCKET CYLINDER | ||||||

| R55 | R60-5-7 | R130 | R200-5 | R210-5 | R220 | R225-7 |

| R260LC-5 | R280 | R290 | R300 | R305-7 | R450-5 | R215-7 |

| R210LC-3 | R335-7 | |||||

cylinder diamete r (mm) | piston rod diameter (mm) | max stroke (mm) | ||

| 40 | 20 | 22 | 25 | 500 |

| 50 | 25 | 28 | 32 | 600 |

| 63 | 32 | 35 | 45 | 800 |

| 80 | 40 | 45 | 55 | 2000 |

| 90 | 45 | 50 | 63 | 2000 |

| 100 | 50 | 55 | 70 | 4000 |

| 110 | 55 | 63 | 80 | 4000 |

| 125 | 63 | 70 | 90 | 4000 |

| 140 | 70 | 80 | 100 | 4000 |

| 150 | 75 | 85 | 105 | 4000 |

| 160 | 80 | 90 | 110 | 4000 |

| 180 | 90 | 100 | 125 | 4000 |

| 200 | 100 | 110 | 140 | 4000 |

| 220 | 110 | 125 | 160 | 4000 |

| 250 | 125 | 140 | 180 | 4000 |

- Q: For example, I press a workpiece with a hydraulic press, and the pressure gauge shows 0.3MPa. Then I change the cylinder pressure. When I type, I choose the 0.3MPa cylinder instead of the inner diameter of the cylinder.

- To see the pressure gauge is arranged in what position, the general pressure gauge installed in the hydraulic station exit, that is the pressure of the hydraulic system;

- Q: Hydraulic oil? Refrigerant? Brake night? What are they? What's the function of it?

- Cooling liquid is used for automobile engine cooling, winter antifreeze, corrosion protection, waterproof scaleLubricating fluid is oil and gear oil, such as ease the friction between the piston and the cylinder wall in the engine

- Q: I would like to ask if the speed of the hydraulic cylinder is related to the load on the piston rod?Proportional flow valve how to type, I currently only know the maximum pressure 2.5Mpa, according to Q=VA count as 0.4L/min, 1L/min can be chosen according to the ratio of flow valve? Is there another way to choose?

- Speed and load independent, mainly related to the flow, piston rod diameter, proportional flow valve type selection, according to flow and pressure selection, specific samples can be checked

- Q: What is the working pressure of the hydraulic cylinder with a diameter of 80?

- I think you should ask about how much work you can do at work. Formula: theoretical output = work pressure x piston area. The piston area 80 cylinder diameter is 3.14*40*40=5026mm^2; if the work pressure is 10MPa; then the theoretical output is 5026x10=50260N, equivalent to 5 tons of force.

- Q: What are the conditions in the hydraulic system with the imported throttle valve? What is the difference between the throttle valve and the outlet valve?

- 2., import throttle speed control, easy to use pressure relay to achieve pressure control;

- Q: press the stroke 3CM, and then use the shearing machine as nitrogen cylinder return stroke, and then press down again 3CM.Consult you, 300 tons of hydraulic cylinder pressure, 28 MPa downward pressure stroke 3CM, and then use a shear plate as nitrogen cylinder return, and then press down again 3CM. 40 times per minute, OK? Is it feasible to do so?I would like to refer to the principle of shearing machine, to do a 3CM stroke 300 tons hydraulic press. Is that feasible? Since I need a very short stroke, I would like to use an ordinary larger cylinder instead of a fast cylinder. The return trip would also like to use nitrogen, which would make the hydraulic part the simplest, not knowing whether I was right or not

- Both pendulum shearing machine and gate shearing machine adopt single acting hydraulic cylinder! Jianhu Huabo hydraulic guillotine shears is accumulator return

- Q: The surface of the hydraulic rod is chromium, and it often causes strain, scratch, electric shock and so on. The routine method is slow to repair and the effect is not satisfactory. Don't want to play with copper, also do not want to use cold, patch method, because of poor adhesion, never long broken. Is there a better way to fix it?

- Brush plating method to repair hydraulic rod, cylinder pull, the best effect. Because the 1. can be repaired on the spot, the trouble of loading and transporting is avoided. 2., coating adhesion is good, no obvious boundaries, repair surface hardness, good wear resistance. 3. low temperature operation will not change the properties of the substrate. Electroplating repair technology is a kind of traditional repair technology to restore the size of parts at low temperature.

- Q: About the problem that hydraulic cylinders can take the place of cylinders

- 1, the hydraulic pressure station is larger;2. hydraulic oil is easy to pollute the surrounding environment;3, the speed and pressure characteristics are different and need to be redesigned and adjusted

- Q: Difference between cylinders of hydraulic cylinders

- The working principle is very simple by using the Pascal principle (F1/A1=F2/A2), the advantages do not need lubricating oil, because his work is medium, and he can realize remote control, can realize stepless speed, no noise etc......

- Q: Hello, which units use hydraulic pneumatic cylinders and more cylinders?. Thank you

- The meter on the unit of the cylinder is big, but there is more.And the hydraulic cylinder bore is greater.

Send your message to us

hydraulic ram for excavator heavy duty machinery

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords