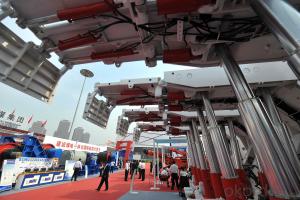

small bore hydraulic ram for boring machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

1.ISO9001:2008

2.Seal:Merkel or Parker

3.Working pressure:16-25Mpa.

4.10 years of experienc

5.Material:CK45

CMAX series engineering hydraulic Cylinder

(1)working pressure:16MPa

(2)Piston diameter: 40-250mm

(3)Seals:Merkel or Parker

(4)Sensor: MTS or Balluff

BOOM,ARM,BUCKET CYLINDER | ||||||

| R55 | R60-5-7 | R130 | R200-5 | R210-5 | R220 | R225-7 |

| R260LC-5 | R280 | R290 | R300 | R305-7 | R450-5 | R215-7 |

| R210LC-3 | R335-7 | |||||

cylinder diamete r (mm) | piston rod diameter (mm) | max stroke (mm) | ||

| 40 | 20 | 22 | 25 | 500 |

| 50 | 25 | 28 | 32 | 600 |

| 63 | 32 | 35 | 45 | 800 |

| 80 | 40 | 45 | 55 | 2000 |

| 90 | 45 | 50 | 63 | 2000 |

| 100 | 50 | 55 | 70 | 4000 |

| 110 | 55 | 63 | 80 | 4000 |

| 125 | 63 | 70 | 90 | 4000 |

| 140 | 70 | 80 | 100 | 4000 |

| 150 | 75 | 85 | 105 | 4000 |

| 160 | 80 | 90 | 110 | 4000 |

| 180 | 90 | 100 | 125 | 4000 |

| 200 | 100 | 110 | 140 | 4000 |

| 220 | 110 | 125 | 160 | 4000 |

| 250 | 125 | 140 | 180 | 4000 |

- Q: What does hydraulic cylinder type "HSG 80/60-1100" mean?

- The complete specifications are as follows:HSG* cylinder head linkage mode -D/d* pressure level - mounting mode * piston rod mounting mode * with buffer * oil port connection type * stroke * mounting distance

- Q: Master, I want to make a set of hydraulic equipment for hydraulic piston and cylinder head with us how to adjust the tolerances. (H refers to the tolerance zone of the hole, f refers to the tolerance zone of the shaft, right? What does H7F8 mean?) I do not understand these written knowledge, it is best to say that the size of the piston head and cylinder bore how to fit, and can take specific figures for example, the best, the more detailed the better. To install the piston ring high speed heating will do, how to solve it, large caliber and long trip for us.

- 1, GB standard: hole tolerance class with uppercase English letters, shaft tolerance class with lower case English letters, H7/f8 refers to the hole and shaft tolerance zone, but the specific tolerance depends on the size of the section, can be examined.

- Q: UG4.0 parts library, what cylinders, motors, cylinders are standard parts for the equipment?

- I give you an online version of it, can go to the site to download the linkable.partcommunity, I have been using CAD material, can download, support UG format and some other CAD format, no requirement for computer system.

- Q: Are hydraulic cylinders, oil cylinders, hydraulic cylinders all the same? What's the difference?

- It's all about one thingI am the repair cylinderThe cylinder is all hydraulic, so it is called a hydraulic cylinder and a hydraulic cylinder, both of which mean one

- Q: Why is the digital hydraulic cylinder not widely used?

- 1, the movement of the plane to do a guide rail, to limit the movement of track;

- Q: What is the essential difference between hydraulic oil and lubricating oil?

- The lubricating oil includes hydraulic oil is a kind of lubricating oil is a general hydraulic oil lubricating oil for a strong oil

- Q: About the problem that hydraulic cylinders can take the place of cylinders

- I suggest changing the hydraulic pressure, because the hydraulic pressure is steady and the force is great. Thank you You can contact any hydraulic problem.

- Q: Why do not the industrial furnace door use the hydraulic cylinder and the cylinder?

- Because the oil in the hydraulic cylinder will be heated, it will affect the oil heating, it is difficult to cool the oil heater, this is the reason, in one may be cost savings

- Q: Difference between cylinders of hydraulic cylinders

- The air pressure cylinder uses air compressor to press air into the cylinder. The principle is also the use of Pascal principle. Advantages are light quality, low price (work medium can be seen everywhere), remote control can be realized, disadvantages such as noise, etc.

- Q: Hello, which units use hydraulic pneumatic cylinders and more cylinders?. Thank you

- Not to answer this question, because the diameter of cylinder is larger, more representative output.

Send your message to us

small bore hydraulic ram for boring machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords