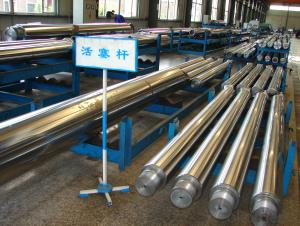

hydraulic ram, telescopic hydraulic ram, hydraulic telescopic ram for tipper truck

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

1.ISO9001:2008

2.Seal:Merkel or Parker

3.Working pressure:16-25Mpa.

4.10 years of experienc

5.Material:CK45

CMAX series engineering hydraulic Cylinder

(1)working pressure:16MPa

(2)Piston diameter: 40-250mm

(3)Seals:Merkel or Parker

(4)Sensor: MTS or Balluff

BOOM,ARM,BUCKET CYLINDER | ||||||

| R55 | R60-5-7 | R130 | R200-5 | R210-5 | R220 | R225-7 |

| R260LC-5 | R280 | R290 | R300 | R305-7 | R450-5 | R215-7 |

| R210LC-3 | R335-7 | |||||

cylinder diamete r (mm) | piston rod diameter (mm) | max stroke (mm) | ||

| 40 | 20 | 22 | 25 | 500 |

| 50 | 25 | 28 | 32 | 600 |

| 63 | 32 | 35 | 45 | 800 |

| 80 | 40 | 45 | 55 | 2000 |

| 90 | 45 | 50 | 63 | 2000 |

| 100 | 50 | 55 | 70 | 4000 |

| 110 | 55 | 63 | 80 | 4000 |

| 125 | 63 | 70 | 90 | 4000 |

| 140 | 70 | 80 | 100 | 4000 |

| 150 | 75 | 85 | 105 | 4000 |

| 160 | 80 | 90 | 110 | 4000 |

| 180 | 90 | 100 | 125 | 4000 |

| 200 | 100 | 110 | 140 | 4000 |

| 220 | 110 | 125 | 160 | 4000 |

| 250 | 125 | 140 | 180 | 4000 |

- Q: What are the conditions in the hydraulic system with the imported throttle valve? What is the difference between the throttle valve and the outlet valve?

- 3, import throttle speed regulation, unlike the export throttle speed control, can bear negative load, so the movement is less smooth. Can be added by back pressure valve to solveNeed to speed sensitive, quick response, with import throttle. If the action is smooth, shock resistance load, with oil return throttling

- Q: How much money machine hele ah, pneumatic hele surface machine, hydraulic machine hele surface what is the difference between ah

- the pump is a standard machine, all over to the car, bicycle pump is a pump, which has sold, so the pneumatic machine general hele surface does not contain the pump price is down two, the price is almost, martini.

- Q: The difference between gas cylinder and cylinder

- The advantages of both gas-liquid pressurized cylinder above two: environmental protection and energy saving, convenient control, adjustment is simple. But the output of travel is limited, suitable for short stroke, large output, and environmental protection and energy saving and low configuration settings.

- Q: always have hydraulic oil leakage, please expert advice, with what seal can avoid, the best zero leakage.

- High pressure and high speed will result in high temperature at the sealing place. The sealing wear and aging will be very quick, even if the trial production effect is ideal, the actual use will be a problem.Increase the surface finish and hardness of piston rodImprove the wear resistance of sealing material at high temperatureIncrease seal quantity, multi stage seal

- Q: Hydraulic principle

- A typical hydraulic system comprises a hydraulic pump, hydraulic oil tank, directional control valve, flow control valve, the working cylinder, plunger valve and pressure relief valve. Three kinds of typical hydraulic pump hydraulic system used in gear pump, vane pump and axial reciprocating pump. Pump is the power component liquid system is the heart of the hydraulic pump control element. (including the flow valve, relief valve, directional valve and proportional valve etc.) for controlling and regulating the fluid pressure. The flow and direction, to meet the performance requirements of equipments, and the realization of various work cycle, the implementation of components to the pressure of the liquid can be converted to mechanical energy, so as to drive the movement of the mechanism.

- Q: We have to design a manual plunger water hydraulic pump, but the wall thickness of the cylinder will not be designed and checked. I follow the sigma delta is not less than PD/2[design is out of 10mm thick, but the teacher said 5mm can withstand the pressure of 150MPa, the material with corrosion resistant stainless steel can. Some of my parameters are the maximum cylinder pressure 140MPa, cylinder size d=18mm (can also be smaller), length 60 ~ 80mm, how can I design wall thickness? thank you very much indeed

- The maximum permissible bearing pressure in the thin-walled tube [P] formula: [P]] =2[sigma phi S (D / S) in the formula: [Sigma - material allowable stress; coefficient of weld - diameter, seamless tube, pipe wall thickness with =1; S-- d--; the inner diameter of the pipe.

- Q: What type of cylinder do you have?

- 1. straight line type: the advantage lies in the simple structure, the cost is low, therefore the small displacement mostly uses the straight line, the inferiority lies in the vibration is bigger.2.V: the advantage is that the structure is compact, the stability is good, the disadvantage lies in the straight line type expensive, suitable for large displacement.3. flat (arrangement can be regarded as V type 180 degree angle): the advantage of ultra low center of gravity, high speed, good stability, the disadvantage is that there are only two car plants in this way: Porsche and Subaru.

- Q: Why do not the industrial furnace door use the hydraulic cylinder and the cylinder?

- Hydraulic cylinder seal ring for industrial furnace door is easy to leak oil

- Q: Structure principle of return nitrogen cylinder of hydraulic shearing machine

- It is a well sealed plunger cylinder with nitrogen enclosed inside. Its function is spring, when pressed, it is compressed. Return the blade back when returning.Ball head lubrication should be done well, otherwise it will be bad.

- Q: Difference between cylinders of hydraulic cylinders

- The air pressure cylinder uses air compressor to press air into the cylinder. The principle is also the use of Pascal principle. Advantages are light quality, low price (work medium can be seen everywhere), remote control can be realized, disadvantages such as noise, etc.

Send your message to us

hydraulic ram, telescopic hydraulic ram, hydraulic telescopic ram for tipper truck

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches