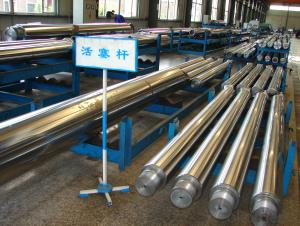

Factory Direct Custom Made Acting Hydraulic Ram

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

1.ISO9001:2008

2.Seal:Merkel or Parker

3.Working pressure:16-25Mpa.

4.10 years of experienc

5.Material:CK45

CMAX series engineering hydraulic Cylinder

(1)working pressure:16MPa

(2)Piston diameter: 40-250mm

(3)Seals:Merkel or Parker

(4)Sensor: MTS or Balluff

BOOM,ARM,BUCKET CYLINDER | ||||||

| R55 | R60-5-7 | R130 | R200-5 | R210-5 | R220 | R225-7 |

| R260LC-5 | R280 | R290 | R300 | R305-7 | R450-5 | R215-7 |

| R210LC-3 | R335-7 | |||||

cylinder diamete r (mm) | piston rod diameter (mm) | max stroke (mm) | ||

| 40 | 20 | 22 | 25 | 500 |

| 50 | 25 | 28 | 32 | 600 |

| 63 | 32 | 35 | 45 | 800 |

| 80 | 40 | 45 | 55 | 2000 |

| 90 | 45 | 50 | 63 | 2000 |

| 100 | 50 | 55 | 70 | 4000 |

| 110 | 55 | 63 | 80 | 4000 |

| 125 | 63 | 70 | 90 | 4000 |

| 140 | 70 | 80 | 100 | 4000 |

| 150 | 75 | 85 | 105 | 4000 |

| 160 | 80 | 90 | 110 | 4000 |

| 180 | 90 | 100 | 125 | 4000 |

| 200 | 100 | 110 | 140 | 4000 |

| 220 | 110 | 125 | 160 | 4000 |

| 250 | 125 | 140 | 180 | 4000 |

- Q: For example, I press a workpiece with a hydraulic press, and the pressure gauge shows 0.3MPa. Then I change the cylinder pressure. When I type, I choose the 0.3MPa cylinder instead of the inner diameter of the cylinder.

- To see the pressure gauge is arranged in what position, the general pressure gauge installed in the hydraulic station exit, that is the pressure of the hydraulic system;

- Q: How is the hydraulic jack refitted into a high pressure inflator?

- We have special pneumatic pumpsJack will hand away part of the copper gasket replacement pneumatic pump lockQing pump connection, the above can use the press

- Q: What is the pivot shaft in the cylinder?

- The hinge shaft is a kind of hydraulic installation method. After installation, the hydraulic cylinder can swing. This cylinder is a hydraulic cylinder with a hinged shaft.

- Q: Can the cylinder be hydraulic?

- Yes. Ordinary cylinder, air driven, medium air, high compressibility of the gas, so the stability is relatively poorOften there is a need for stable output and movement, at which point the cylinder can be changed to oil and the compressibility of the oilLower, it will be a lot of stability

- Q: Hydraulic cylinder application

- Hello, hydraulic cylinder products are widely used in metallurgy, lifting, mining, transportation, ships, forging, machine tools, coal, oil, chemical, scientific research, military, and other industries. It is a hydraulic actuator that converts hydraulic energy into linear motion and mechanical work.The cylinder converts the pressure energy of the compressed air into mechanical energy, and the drive mechanism acts as a linear reciprocating motion, swinging and rotating motion. Mainly used in printing (tension control), semiconductor (spot welder, chip grinding), automatic control, robot and so on.

- Q: used as the form of a connecting rod or piston in an automobile crankshaft. What is the minimum allowable value for such a hydraulic cylinder?. This way, the supply of oil cylinder in the rear, I ask the output cylinder allowed the maximum number of transfer, such as cooling good, the highest output can be transferred. How many manufacturers are there in the market?.

- Yes, but this requirement is very high, and the input power is also greater. I don't know what you do

- Q: How to distinguish hydraulic cylinders and cylinders?

- Can be from the weight, oil port connector, respectively. The cylinder is usually made of Q235 or cast iron, the quality is heavier; the cylinder is usually made of alloy steel, and the quality is lighter. The joint of the cylinder is usually flanged connection or pipe thread connection; the joint of the cylinder is usually expanded or inserted or directly sheathed by the hose.

- Q: What is the essential difference between hydraulic oil and lubricating oil?

- Hydraulic oil is used for cylinder work! Lubricating oil is used for bearings! The place is different!

- Q: Computer automatic packing machine, cylinder voice suddenly become larger, how to solve?

- The reason why the hydraulic cylinder does not move is possible:1 hydraulic cylinder seal is not strict with hydraulic oil leakage will cause the pressure in the hydraulic cylinder is not enough to overcome the pressure of the plunger cylinder without action;

- Q: Is the hydraulic cylinder at rated pressure the greater the stroke and the greater the pressure, is there a formula?

- Bore diameter: hydraulic cylinder jacket, unit mm;Hydraulic pressure: hydraulic system to provide the maximum hydraulic pressure, unit MPa * 10.Such as:If the bore 280mm, hydraulic pressure of 25 MPa, then the cylinder thrust3.14 * (28 / 2) x 2 (25 x 10) / 1000=153.86 (ton)

Send your message to us

Factory Direct Custom Made Acting Hydraulic Ram

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches