Factory Direct Custom Made Double Acting Hydraulic Ram Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

1.ISO9001:2008

2.Seal:Merkel or Parker

3.Working pressure:16-25Mpa.

4.10 years of experienc

5.Material:CK45

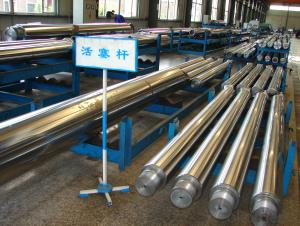

CMAX series engineering hydraulic Cylinder

(1)working pressure:16MPa

(2)Piston diameter: 40-250mm

(3)Seals:Merkel or Parker

(4)Sensor: MTS or Balluff

BOOM,ARM,BUCKET CYLINDER | ||||||

| R55 | R60-5-7 | R130 | R200-5 | R210-5 | R220 | R225-7 |

| R260LC-5 | R280 | R290 | R300 | R305-7 | R450-5 | R215-7 |

| R210LC-3 | R335-7 | |||||

cylinder diamete r (mm) | piston rod diameter (mm) | max stroke (mm) | ||

| 40 | 20 | 22 | 25 | 500 |

| 50 | 25 | 28 | 32 | 600 |

| 63 | 32 | 35 | 45 | 800 |

| 80 | 40 | 45 | 55 | 2000 |

| 90 | 45 | 50 | 63 | 2000 |

| 100 | 50 | 55 | 70 | 4000 |

| 110 | 55 | 63 | 80 | 4000 |

| 125 | 63 | 70 | 90 | 4000 |

| 140 | 70 | 80 | 100 | 4000 |

| 150 | 75 | 85 | 105 | 4000 |

| 160 | 80 | 90 | 110 | 4000 |

| 180 | 90 | 100 | 125 | 4000 |

| 200 | 100 | 110 | 140 | 4000 |

| 220 | 110 | 125 | 160 | 4000 |

| 250 | 125 | 140 | 180 | 4000 |

- Q: What is the bad effect of the engine oil pressure on the engine when the oil pressure is too high or too low?

- Engine oil pressure is too high or too low, the hydraulic valve configuration is the opportunity to start the engine underpowered or too much power, damage to engine life. 1, the engine is a kind of machine that can convert other forms into mechanical energy, such as internal combustion engine (gasoline engine, etc.), external combustion engine (Stryn engine, steam engine, etc.), motor, etc.. Internal combustion engines, for example, usually convert chemical energy into mechanical energy.

- Q: What does hydraulic cylinder type "HSG 80/60-1100" mean?

- The complete specifications are as follows:HSG* cylinder head linkage mode -D/d* pressure level - mounting mode * piston rod mounting mode * with buffer * oil port connection type * stroke * mounting distance

- Q: How do I calculate the flow rate of the hydraulic cylinder?

- Flow rate Q= speed V * hydraulic cylinder cross sectional area AWhen calculating, pay attention to the transformation of units

- Q: Can you tell me if the cylinder can be changed into an oil cylinder (low pressure)?

- Yes, as long as your oil pressure is below 8KG on the line, but it is difficult to get such oil pressure, the general pressure of the pump above 70KG, if filled into the cylinder, it will burst.

- Q: What is the working pressure of the hydraulic cylinder with a diameter of 80?

- I think you should ask about how much work you can do at work. Formula: theoretical output = work pressure x piston area. The piston area 80 cylinder diameter is 3.14*40*40=5026mm^2; if the work pressure is 10MPa; then the theoretical output is 5026x10=50260N, equivalent to 5 tons of force.

- Q: Is the cylinder usually faster than the hydraulic cylinder?

- Yes, but the output power of the cylinder is large

- Q: What is the difference between the cylinder seal and the cylinder seal?

- The medium of bees is different. One is gas sealed, and the other is liquid sealed.

- Q: What do three hydraulic cylinders need? Is it okay to use PLC? Specific point, I do not understand electricity 10Two cylinder and clamp the workpiece, a feeding cylinder, a hydraulic cylinder to the specified length after the 1 clamping, then another hydraulic cylinder 2 to the workpiece chamfering quickly return hydraulic cylinder 3, cutting, cutting material after rapid return, the hydraulic cylinder 1 and a clamping cylinder and cylinder return return evacuation then, the next clip material feeding cycle. ----...

- Yes, you need relays, solenoid valves, push buttons, switches, switches, and so on. It depends on what you need

- Q: What can be used in hydraulic equipment factory

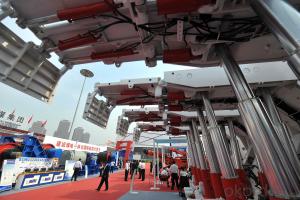

- Hydraulic systems are widely used in today's construction machinery. Although there are electrical, pneumatic or mechanical systems to choose from, hydraulic systems have been used more and more. For example, on many excavators, the hydraulic system is used to lift and lower the boom, move the bucket, and perform the turn motion of the upper structure of the machine.Why use a hydraulic system? There are many reasons, partly because of the wide use, high efficiency and simple characteristics of the hydraulic system in power transmission. The task of a hydraulic system is to change power from one form to another.

- Q: Why is the digital hydraulic cylinder not widely used?

- 1, the movement of the plane to do a guide rail, to limit the movement of track;

Send your message to us

Factory Direct Custom Made Double Acting Hydraulic Ram Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches