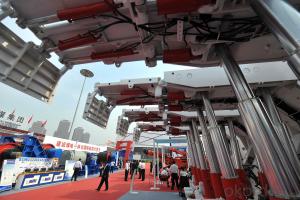

machinery hydraulic ram for excavator, truck, tractor, loader, heavy duty machinery

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

1.ISO9001:2008

2.Seal:Merkel or Parker

3.Working pressure:16-25Mpa.

4.10 years of experienc

5.Material:CK45

CMAX series engineering hydraulic Cylinder

(1)working pressure:16MPa

(2)Piston diameter: 40-250mm

(3)Seals:Merkel or Parker

(4)Sensor: MTS or Balluff

BOOM,ARM,BUCKET CYLINDER | ||||||

| R55 | R60-5-7 | R130 | R200-5 | R210-5 | R220 | R225-7 |

| R260LC-5 | R280 | R290 | R300 | R305-7 | R450-5 | R215-7 |

| R210LC-3 | R335-7 | |||||

cylinder diamete r (mm) | piston rod diameter (mm) | max stroke (mm) | ||

| 40 | 20 | 22 | 25 | 500 |

| 50 | 25 | 28 | 32 | 600 |

| 63 | 32 | 35 | 45 | 800 |

| 80 | 40 | 45 | 55 | 2000 |

| 90 | 45 | 50 | 63 | 2000 |

| 100 | 50 | 55 | 70 | 4000 |

| 110 | 55 | 63 | 80 | 4000 |

| 125 | 63 | 70 | 90 | 4000 |

| 140 | 70 | 80 | 100 | 4000 |

| 150 | 75 | 85 | 105 | 4000 |

| 160 | 80 | 90 | 110 | 4000 |

| 180 | 90 | 100 | 125 | 4000 |

| 200 | 100 | 110 | 140 | 4000 |

| 220 | 110 | 125 | 160 | 4000 |

| 250 | 125 | 140 | 180 | 4000 |

- Q: This is the model of a hydraulic buffer tank used on an oil rig. Who can explain the meaning of this model to me, especially the meaning of 550*905, and also provide the best drawings

- HSG--- double acting single piston hydraulic cylinder, piston type K--- card key, 01--- for the Y type sealing ring, 160/110E--- bore diameter is 110, 160, a pressure of 16MPa, 5221---5 said the cylinder head or cylinder middle flange connection, 2 piston rod end thread, 2 (second 2) the cylinder head end buffer 1 oil port internal thread; 550 stroke, 905 for the minimum installation distance.

- Q: What kind of material is the hydraulic cylinder of loader?

- 2, the cause of the wear and tear is mainly caused by insufficient lubrication. The piston and piston ring move at high speed in the cylinder mirror. Under lubrication. Between the working face can not form the oil film, both friction surface has extremely small part, the metal direct contact, because the friction formation partial high heat dissipation does not walk, but when accumulates to a certain extent, will cause two people to melt the adhesion. At this time, if the oil film can be timely recovery, cleaning and cooling, so that these tiny weld parts fall off without expansion; if the oil film recovery slow, weld expansion, resulting in abnormal melting wear occurred in a large area, which is usually called cylinder. Melting wear generally occurs on the upper part of the cylinder mirror, near the first ring at the top dead point, where localized metal melting is stuck and uneven uneven edges of groove marks and folds. Cylinderscoring phenomenon is easy to happen in production without running internal combustion engine immediately load working conditions. Because the internal combustion engine cylinder is not thicker, the oil film is not easy to form, and the cylinder mirror surface and the piston surface convex place often have tiny metal contact, thus causing melting wear and even killing phenomenon.

- Q: press the stroke 3CM, and then use the shearing machine as nitrogen cylinder return stroke, and then press down again 3CM.Consult you, 300 tons of hydraulic cylinder pressure, 28 MPa downward pressure stroke 3CM, and then use a shear plate as nitrogen cylinder return, and then press down again 3CM. 40 times per minute, OK? Is it feasible to do so?I would like to refer to the principle of shearing machine, to do a 3CM stroke 300 tons hydraulic press. Is that feasible? Since I need a very short stroke, I would like to use an ordinary larger cylinder instead of a fast cylinder. The return trip would also like to use nitrogen, which would make the hydraulic part the simplest, not knowing whether I was right or not

- The difference is that the pendulum shear is the return cylinder of the nitrogen return cylinder! Both pendulum shearing machine and gate shearing machine adopt single acting hydraulic cylinder! Jianhu Huabo hydraulic guillotine shears is accumulator return

- Q: Does the car have no cylinder pressure? Is it related to the hydraulic bottom support?

- It has something to do with the tight seal of the cylinder, where the valve is hung or burned

- Q: How much money machine hele ah, pneumatic hele surface machine, hydraulic machine hele surface what is the difference between ah

- Around one thousand, the cruel is cylinder powered hydraulic cylinder is powered, difference is that practice is factory shipments of hydraulic machine general hele surface is complete,

- Q: Can the cylinder be hydraulic?

- Yes. Ordinary cylinder, air driven, medium air, high compressibility of the gas, so the stability is relatively poorOften there is a need for stable output and movement, at which point the cylinder can be changed to oil and the compressibility of the oilLower, it will be a lot of stability

- Q: used as the form of a connecting rod or piston in an automobile crankshaft. What is the minimum allowable value for such a hydraulic cylinder?. This way, the supply of oil cylinder in the rear, I ask the output cylinder allowed the maximum number of transfer, such as cooling good, the highest output can be transferred. How many manufacturers are there in the market?.

- Yes, but this requirement is very high, and the input power is also greater. I don't know what you do

- Q: Why is the digital hydraulic cylinder not widely used?

- 2, hydraulic system plus flow flow valve; 3, do synchronous cylinder.

- Q: What's the difference between the cylinder and the hydraulic?

- The cylinder is compressed air as the power source, installation, use and maintenance are very simple and convenient, hydraulic cylinder is hydraulic oil as the power source of great output.

- Q: Difference between cylinders of hydraulic cylinders

- The two principle is the same, but the working medium is not the same, one is hydraulic oil, and the other is gasThe hydraulic cylinder is the use of pump oil into the cylinder, on the way to a series of valves such as benefits flow valve valve valve sequence valve check valve control, the main work is the process of the machine is simple and not, some do not need to.

Send your message to us

machinery hydraulic ram for excavator, truck, tractor, loader, heavy duty machinery

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches