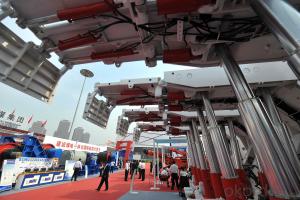

machinery hydraulic ram for heavy duty machinery

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

1.ISO9001:2008

2.Seal:Merkel or Parker

3.Working pressure:16-25Mpa.

4.10 years of experienc

5.Material:CK45

CMAX series engineering hydraulic Cylinder

(1)working pressure:16MPa

(2)Piston diameter: 40-250mm

(3)Seals:Merkel or Parker

(4)Sensor: MTS or Balluff

BOOM,ARM,BUCKET CYLINDER | ||||||

| R55 | R60-5-7 | R130 | R200-5 | R210-5 | R220 | R225-7 |

| R260LC-5 | R280 | R290 | R300 | R305-7 | R450-5 | R215-7 |

| R210LC-3 | R335-7 | |||||

cylinder diamete r (mm) | piston rod diameter (mm) | max stroke (mm) | ||

| 40 | 20 | 22 | 25 | 500 |

| 50 | 25 | 28 | 32 | 600 |

| 63 | 32 | 35 | 45 | 800 |

| 80 | 40 | 45 | 55 | 2000 |

| 90 | 45 | 50 | 63 | 2000 |

| 100 | 50 | 55 | 70 | 4000 |

| 110 | 55 | 63 | 80 | 4000 |

| 125 | 63 | 70 | 90 | 4000 |

| 140 | 70 | 80 | 100 | 4000 |

| 150 | 75 | 85 | 105 | 4000 |

| 160 | 80 | 90 | 110 | 4000 |

| 180 | 90 | 100 | 125 | 4000 |

| 200 | 100 | 110 | 140 | 4000 |

| 220 | 110 | 125 | 160 | 4000 |

| 250 | 125 | 140 | 180 | 4000 |

- Q: What does hydraulic cylinder type "HSG 80/60-1100" mean?

- For more information, you can see the mechanical design manual, Cheng Daxian editor, volume fifth, twenty-first pages of -305 hydraulic transmission.

- Q: What are the conditions in the hydraulic system with the imported throttle valve? What is the difference between the throttle valve and the outlet valve?

- 3, import throttle speed regulation, unlike the export throttle speed control, can bear negative load, so the movement is less smooth. Can be added by back pressure valve to solveNeed to speed sensitive, quick response, with import throttle. If the action is smooth, shock resistance load, with oil return throttling

- Q: How to distinguish hydraulic cylinders and cylinders?

- Hydraulic cylinders, without external bolts, have most of the cylinders;The inlet and outlet are screwed and the cylinder is straight in;

- Q: The difference between gas cylinder and cylinder

- The advantages of both gas-liquid pressurized cylinder above two: environmental protection and energy saving, convenient control, adjustment is simple. But the output of travel is limited, suitable for short stroke, large output, and environmental protection and energy saving and low configuration settings.

- Q: How to remove the hydraulic cylinder oil seal?

- Is the O ring squeezed out? The front cover should be threaded, carefully to see if there are holes installed, there should be 2 or 4, is not to be painted over, if not, must use the flat shovel.

- Q: Can cylinder be used as cylinder, cylinder and hydraulic cylinder, Yantai hydraulic cylinder?

- That is, the seals are not the same, the cylinder seals may be less oil than the hydraulic cylinder.

- Q: Hydraulic principle

- Hydraulic transmission is also called volume hydraulic transmission, is liquid as the medium, the transmission device to transmit energy and control the use of liquid pressure energy and kinetic energy. Usually the liquid medium using the hydraulic system with the remaining liquid pressure energy is called hydraulic oil.

- Q: What is the essential difference between hydraulic oil and lubricating oil?

- Definition of hydraulic oil,Hydraulic oil pressure is the hydraulic medium used in hydraulic system with liquid pressure energy. It plays the role of energy transmission, system lubrication, corrosion prevention, rust prevention and cooling in the hydraulic system. For the hydraulic oil, should first meet the requirements of the hydraulic device in the operating temperature and the starting temperature of the liquid viscosity, the viscosity change of oil is directly related to hydraulic operation, transmission efficiency and transmission precision, but also oil viscosity temperature properties and shear stability should meet the needs of different uses of the proposed.Definition of lubricating oilLubricating oil is used in various types of machinery to reduce friction, protection of machinery and processing parts of liquid lubricants, mainly from lubrication, cooling, rust, cleaning, sealing and buffering.By contrast, some of the effects of hydraulic oils and lubricants are the same... But they differ in their environmental conditions and are higher than those for hydraulic fluids...

- Q: What type of cylinder do you have?

- 1) from the cylinder piston to withstand the pressure of gas is one-way or two-way classification (1) single acting cylinder: the piston of the cylinder can only be one-way pressure driven, reverse need to use external force. (2) double acting cylinder: the piston of the cylinder is driven by the air pressure in the two directions of both positive and negative directions. 2) classify the installation form of cylinder (1) fixed cylinder: cylinder block fixed. (2) axle pin type cylinder: the cylinder block can swing around the fixed axis pin at a certain angle. (3) rotary cylinder: the cylinder block is usually fixed on the main shaft of the machine tool, and can rotate with the main shaft of the machine. This kind of cylinder is usually used in the pneumatic chuck of the machine tool.

- Q: Difference between cylinders of hydraulic cylinders

- The working principle is very simple by using the Pascal principle (F1/A1=F2/A2), the advantages do not need lubricating oil, because his work is medium, and he can realize remote control, can realize stepless speed, no noise etc......

Send your message to us

machinery hydraulic ram for heavy duty machinery

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords