HR Steel Angles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Hot Rolled Angle Steel

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2. Invoicing on theoretical weight or actual weight as customer request3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

5.Sizes:

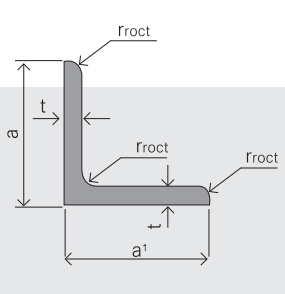

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

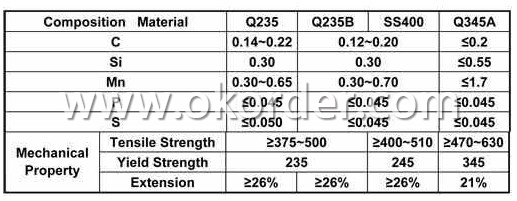

6. Material details:

Usage & Applications Hot Rolled Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Hot Rolled Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q: Can steel H-beams be used for supporting conveyor systems?

- Yes, steel H-beams can be used for supporting conveyor systems. The structural properties of steel H-beams, such as their strength and load-bearing capacity, make them an ideal choice for providing stable and durable support for conveyor systems.

- Q: Are steel H-beams suitable for convention halls?

- Convention halls commonly utilize steel H-beams due to their strength and versatility. H-beams offer exceptional load-bearing capabilities, enabling the creation of spacious and expansive areas within these halls. Moreover, their structural stability is ideal for supporting the substantial weight of equipment, lighting rigs, and other necessary installations. Additionally, the ease of fabrication and installation of steel H-beams makes them a practical choice for extensive projects. In summary, steel H-beams are a dependable and appropriate choice for the construction of convention halls.

- Q: How do steel H-beams perform in terms of impact resistance?

- The excellent impact resistance of Steel H-beams is well-known. Their structural design, characterized by wide flanges and a vertical web, ensures high durability and strength when exposed to impact forces. This feature makes them particularly suitable for applications where heavy loads or potential impacts are a concern, such as in construction projects or industrial settings. The wide flanges of H-beams distribute the impact load across a larger area, minimizing concentrated stress points and preventing failure. Moreover, the vertical web provides added rigidity and stability, enhancing the overall resistance of the beam against impacts. Additionally, steel possesses inherent toughness and resilience as a material, enabling it to absorb and dissipate energy from impacts effectively. Steel H-beams are often manufactured using top-quality structural steel, further enhancing their impact resistance properties. To summarize, the structural design of steel H-beams, combined with the material properties of steel, results in excellent impact resistance. They can withstand heavy loads and potential impacts, making them a dependable choice for a variety of applications that require structural strength and durability.

- Q: What are the common defects found in steel H-beams?

- There are several common defects that can be found in steel H-beams. One of the most common defects is surface imperfections, such as scratches, pits, or dents. These can occur during the manufacturing process or due to mishandling during transportation or storage. Another common defect is welding defects. H-beams are often fabricated by welding different sections together, and if the welding process is not performed properly, it can result in defects such as cracks, lack of fusion, or excessive weld spatter. Misalignments are also common defects in steel H-beams. This can occur when the flanges or webs of the beam are not properly aligned, resulting in an uneven or twisted shape. Misalignments can affect the overall structural integrity of the beam and may require corrective measures to ensure proper functionality. In addition, dimensional deviations can be found in H-beams. This can include variations in length, width, or height, which can affect the overall stability and load-bearing capacity of the beam. Lastly, corrosion is another defect that can occur in steel H-beams, especially in outdoor or corrosive environments. If the beam is not properly protected with coatings or if there are gaps in the protective layer, it can lead to rust formation and deterioration of the steel. Overall, it is important to inspect steel H-beams for these common defects to ensure their quality and structural integrity. Regular maintenance, proper handling, and adherence to manufacturing standards can help prevent these defects and ensure the longevity and performance of the beams.

- Q: Are steel H-beams resistant to impact and vibration?

- Steel H-beams have a high resistance to impact and vibration due to their H-shape design. This design provides stability and strength, making them suitable for withstanding various external forces, such as impacts and vibrations. The H-beams distribute the load evenly along their length, reducing stress concentration and preventing potential damage. Furthermore, steel is known for its durability and toughness, which enhances the H-beams' resistance to impact and vibration. As a result, steel H-beams are extensively used in industries like construction and engineering, where structural stability and resistance to external forces are vital.

- Q: How do steel H-beams perform in terms of torsion resistance?

- Steel H-beams are known for their excellent torsion resistance properties. The H-shape design of these beams helps distribute the load evenly, making them highly resistant to torsion forces. The horizontal flanges and vertical web of the beam work together to resist twisting and bending moments, providing structural stability and preventing deformation. Additionally, the use of high-quality steel in H-beams enhances their torsion resistance, as steel is a strong and durable material that can withstand significant forces without yielding or breaking. Overall, steel H-beams are considered to be one of the best options for applications that require high torsion resistance, such as building frames, bridges, and industrial structures.

- Q: Can Steel H-Beams be used in retail or commercial building construction?

- Yes, Steel H-Beams can be used in retail or commercial building construction. These beams are commonly used in large-scale construction projects due to their high strength and load-bearing capacity. They provide structural support and stability, making them suitable for constructing large commercial and retail buildings.

- Q: How do steel H-beams contribute to the overall structural integrity of a building?

- Steel H-beams contribute to the overall structural integrity of a building by providing strength, support, and stability. These beams are designed to carry heavy loads and distribute the weight evenly across the building's framework. Their shape, with a horizontal top and bottom flange connected by a vertical web, allows for efficient load-bearing and resistance to bending or twisting forces. As a result, H-beams enhance the building's ability to withstand external pressures such as wind, seismic activity, or heavy equipment. Overall, steel H-beams play a crucial role in ensuring the structural stability and safety of a building.

- Q: What are the limitations of steel H-beams?

- There are several limitations associated with steel H-beams. Firstly, steel H-beams have a relatively high cost compared to other building materials such as wood or concrete. This cost can be a limiting factor for smaller-scale construction projects or those with budget constraints. Secondly, steel H-beams are heavy and require specialized equipment for transportation and installation. This can add complexity and cost to a construction project, particularly if access to the site is challenging or limited. Another limitation is that steel H-beams are susceptible to corrosion, especially in environments with high humidity or exposure to saltwater. Over time, this corrosion can weaken the structural integrity of the beams, leading to potential safety hazards and maintenance requirements. Additionally, steel H-beams have limited design flexibility compared to other materials. They are typically straight and inflexible, making it more challenging to incorporate complex architectural or structural designs. Lastly, steel H-beams have limited fire resistance. Steel is a good conductor of heat, and in the event of a fire, the H-beams can quickly transfer heat throughout the structure, potentially compromising its stability. Fire protection measures such as fireproof coatings or additional fire-resistant materials may be necessary to mitigate this limitation. Overall, while steel H-beams offer many advantages in terms of strength and durability, their limitations in terms of cost, weight, corrosion susceptibility, design flexibility, and fire resistance should be carefully considered when selecting the appropriate building material for a construction project.

- Q: Are steel H-beams suitable for seismic zones?

- Yes, steel H-beams are suitable for seismic zones. Steel is a highly durable and ductile material that has been widely used in seismic regions due to its ability to withstand seismic forces. H-beams, also known as I-beams, are specifically designed to provide structural support and stability in various applications, including seismic zones. The H-beam's unique shape, with a wider flange and a narrower web, allows it to distribute loads evenly and efficiently. This design enhances its load-bearing capacity and resistance to bending moments, making it suitable for seismic conditions. The H-beam's cross-sectional shape also provides better resistance against lateral forces, which are common during seismic events. In addition, steel H-beams can be fabricated to meet specific seismic design requirements. They can be reinforced with additional steel plates or braces to enhance their strength and stiffness. These beams can also be designed to provide flexibility and ductility, which are crucial in absorbing and dissipating energy during earthquakes. Furthermore, steel H-beams offer several advantages in seismic zones. They are non-combustible, which reduces the risk of fire-related incidents. Steel beams are also lightweight compared to other construction materials, making them easier to transport and install in earthquake-prone regions. Additionally, steel is a recyclable material, contributing to sustainable construction practices. However, it is important to note that the suitability of steel H-beams in seismic zones depends on various factors, such as design considerations, foundation conditions, and local building codes. Consulting with structural engineers and adhering to seismic design guidelines is crucial to ensure the safe and effective use of steel H-beams in seismic regions.

Send your message to us

HR Steel Angles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords