Hot Rolled H-Beam Structure Steel Q235 Good Price Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Hot Rolled H-Beam Steel

1. Standard: JIS G3101

2. Grade: SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

SIZE(mm) | DIMENSION(kg/m) |

100*100 | 16.9 |

125*125 | 23.6 |

150*75 | 14 |

150*150 | 31.1 |

148*100 | 20.7 |

198*99 | 17.8 |

200*100 | 20.9 |

248*124 | 25.1 |

250*125 | 29 |

300*150 | 36.7 |

298*149 | 32 |

200*200 | 49.9 |

294*200 | 55.8 |

346*174 | 41.2 |

350*175 | 49.4 |

244*175 | 43.6 |

175*175 | 40.4 |

294*200 | 55.8 |

298*201 | 64.4 |

346*174 | 41.2 |

350*175 | 49.4 |

400*200 | 65.4 |

396*199 | 56.1 |

450*200 | 74.9 |

446*199 | 65.1 |

340*250 | 78.1 |

500*200 | 88.1 |

300*150 | 36.7 |

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

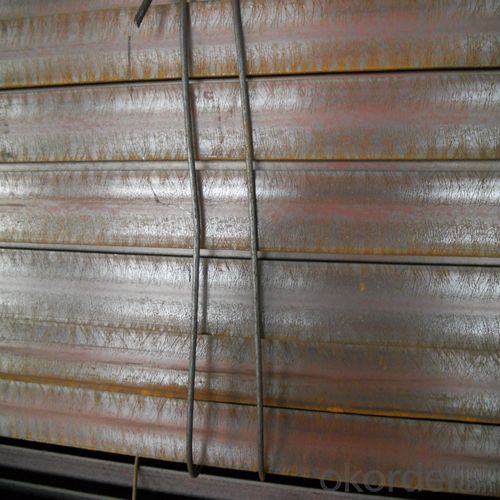

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

- Q: Are Steel H-Beams resistant to termite or insect damage?

- Steel H-beams are resistant to termite or insect damage. They differ from wooden beams in that they do not offer a source of nourishment for termites or other insects, thus making them highly resistant to infestation. Through the combination of iron and carbon, steel beams are created, which do not allure or sustain termite colonies. This resistance to termite or insect damage serves as one of the numerous benefits of incorporating steel H-beams into construction projects, guaranteeing the beams' structural solidity and long lifespan.

- Q: Can steel H-beams be used in theater or auditorium construction?

- Yes, steel H-beams can be used in theater or auditorium construction. Steel H-beams are widely used in construction due to their high strength-to-weight ratio, durability, and versatility. These beams provide a robust structural framework that can support heavy loads, making them suitable for large-scale projects like theaters and auditoriums. The H-shaped cross-section of these beams distributes the load evenly along their length, ensuring stability and structural integrity. Moreover, steel H-beams can be easily fabricated and installed, allowing for efficient construction processes. Overall, steel H-beams are an excellent choice for theater or auditorium construction, providing the necessary strength and support for these types of structures.

- Q: Are steel H-beams suitable for industrial structures?

- Industrial structures can benefit greatly from the use of steel H-beams. These beams, also known as I-beams or universal beams, are specifically designed to handle heavy loads and provide structural stability. Their unique shape, featuring a wider flange and narrower web, allows for even weight distribution and resistance against bending or twisting forces. Steel H-beams possess several advantages that make them an ideal choice for industrial structures. Firstly, they have a high strength-to-weight ratio, meaning they can support heavy loads while remaining relatively lightweight. This not only makes them cost-effective but also easier to handle during the construction process. Additionally, steel is a durable material that can withstand harsh environmental conditions and resist corrosion, ensuring the longevity and safety of the structure. Another advantage of steel H-beams is their versatility. They can be easily fabricated to different lengths and sizes, providing flexible design options and accommodating various construction requirements. Furthermore, these beams can be joined together either by bolting or welding, allowing for the creation of larger structural components. This makes them suitable for constructing wide-span industrial buildings or supporting heavy machinery and equipment. Moreover, steel H-beams offer excellent structural integrity and stability. Their shape provides resistance against bending and torsion, making them capable of withstanding dynamic loads and seismic forces. This makes them particularly well-suited for industrial structures that are exposed to heavy machinery operations, vibrations, or potential impacts. To summarize, steel H-beams are highly suitable for industrial structures due to their strength, durability, versatility, and stability. They possess efficient load-bearing capabilities, enabling the construction of strong and reliable industrial buildings that can withstand heavy loads and harsh environmental conditions.

- Q: How do steel H-beams perform under heavy loads or stresses?

- Steel H-beams are specifically designed to handle heavy loads and stresses. Due to their unique shape, with a wide flange and a narrow web, H-beams are highly resistant to bending and twisting forces. This structural feature allows them to efficiently distribute heavy loads and minimize deflection, making them suitable for a wide range of applications such as bridges, buildings, and industrial structures. Under heavy loads or stresses, steel H-beams maintain their structural integrity and provide excellent support. The wide flange of the beam allows it to resist compression forces, while the narrow web helps it withstand tension forces. This combination of strength and rigidity makes H-beams ideal for supporting vertical loads, as well as for horizontal loads such as wind or seismic forces. Moreover, the use of steel as the primary material for H-beams provides additional benefits. Steel has high tensile strength, which means it can resist a significant amount of pulling or stretching forces without deformation or failure. Steel is also known for its durability, corrosion resistance, and fire resistance properties, ensuring the long-term stability and safety of structures even under heavy loads. In summary, steel H-beams excel in performance under heavy loads or stresses. Their unique shape and material properties allow them to efficiently distribute and resist various types of forces, making them a reliable choice for structural applications where strength and stability are crucial.

- Q: What are the transportation considerations for steel H-beams?

- When it comes to transporting steel H-beams, there are a few things to keep in mind. First and foremost, their size, weight, and safety requirements are of utmost importance. Let's start with the size of these beams. They tend to be quite large and bulky, ranging from a few meters to over 20 meters in length. Because of this, special arrangements may need to be made for transportation. Depending on the distance and available infrastructure, flatbed trucks, trailers, or even railcars may be necessary. It's also worth noting that the width and height of the beams might require special permits or escorts to ensure compliance with road regulations. Moving on to weight, it's a crucial factor to consider. Steel H-beams can weigh several tons, depending on their size. That's why it's essential to make sure that the transportation equipment, including the vehicles and lifting apparatus, can safely handle the weight. In some cases, specialized cranes or forklifts may be needed for loading and unloading the beams at both ends of the journey. Safety is another critical aspect when it comes to transporting steel H-beams. Given their size and weight, it's important to secure and brace them properly to prevent any shifting or tipping during transit. This might involve using chains, straps, or other restraints to fasten the beams to the transport vehicle or container. Additionally, it's crucial to protect the beams from the elements, such as rain or snow, to prevent any corrosion or damage while on the move. Lastly, logistical considerations should not be overlooked. This entails determining the most efficient route for transportation, taking into account factors like road conditions, weight restrictions, and traffic congestion. It may also involve coordinating delivery schedules to ensure that the beams reach their destination within the required timeframe. In summary, successfully and efficiently delivering steel H-beams requires careful management of their size, weight, safety, and logistics.

- Q: What are the common connections used for steel H-beams?

- The common connections used for steel H-beams are typically welded or bolted connections.

- Q: How do steel H-beams perform in areas with high humidity?

- Steel H-beams are renowned for their remarkable strength and durability, making them a favored option for diverse construction projects. In terms of regions with elevated humidity levels, steel H-beams exhibit exceptional performance. One of the primary merits of steel lies in its ability to resist moisture and corrosion. Usually, steel H-beams are coated with protective finishes or galvanized to enhance their resistance against rust and corrosion. These coatings function as a barrier, preventing moisture from infiltrating the beam's surface and causing harm. High humidity can result in the accumulation of moisture in the atmosphere, which may potentially inflict structural damage on specific materials. However, steel H-beams are immune to this issue. Their sturdy construction and corrosion-resistant coatings ensure their ability to withstand the challenges posed by humid environments. Furthermore, steel H-beams possess excellent load-bearing capabilities, which are vital for areas characterized by high humidity. Moisture in the atmosphere can sometimes weaken certain materials, compromising their structural integrity. Nonetheless, steel H-beams retain their strength and stability, even in humid conditions. It is important to note that regular maintenance and inspections are still necessary to ensure the long-term performance of steel H-beams in high humidity areas. This includes conducting routine checks for any signs of corrosion or damage to the protective coatings. By promptly addressing any emerging issues, the lifespan and performance of the steel H-beams can be maximized. In conclusion, steel H-beams are a dependable choice for areas with high humidity due to their resistance to moisture, corrosion, and their excellent load-bearing capabilities. With proper maintenance, these beams can provide enduring structural support, even in challenging environmental conditions.

- Q: What are the different types of steel H-beam connections used in bridge design?

- Bridge design commonly utilizes multiple types of steel H-beam connections to ensure stability and integrity. The following connection types are frequently employed: 1. Welded Connections: The most prevalent connection type involves melting and fusing H-beams together. Welded connections offer exceptional strength and rigidity, making them suitable for various bridge types. 2. Bolted Connections: High-strength bolts are used to connect H-beams, providing flexibility for disassembly and maintenance. However, bolted connections may not offer the same strength and rigidity as welded connections. 3. Riveted Connections: Previously common but now rare, riveted connections employ steel rivets to join H-beams. While providing good strength and durability, they can be time-consuming and expensive to install compared to other methods. 4. Moment Connections: These connections are utilized to transfer bending moments between H-beams. They offer high rigidity and are often used in bridge designs anticipating large loads or forces. 5. Shear Connections: Designed to transfer shear forces between H-beams, these connections are crucial for the bridge's stability and integrity, particularly in areas with significant horizontal forces. 6. Composite Connections: Composite connections combine steel H-beams with materials like concrete or timber. These connections provide the benefits of both materials, with steel offering strength and the additional material providing desirable properties like fire resistance or aesthetics. Ultimately, the choice of H-beam connection type depends on factors like bridge design, load requirements, and construction methods. Each type has its own advantages and limitations, and the selection should consider the specific needs and considerations of the bridge project.

- Q: What does "welding H" steel set "vertical" and "corrective processing" mean?

- The steel plant produces H steel with a special machine to process a 500*300*12*10 H steel of a length of 12 meters

- Q: How do steel H-beams compare to other building materials in terms of strength?

- Steel H-beams are widely regarded as one of the strongest building materials available in the construction industry. The unique shape of the H-beam provides exceptional strength and structural integrity, making it highly suitable for various applications. Compared to other building materials such as wood, concrete, or aluminum, steel H-beams offer significant advantages in terms of strength. The high tensile strength of steel allows H-beams to withstand heavy loads and resist bending or warping under pressure, making them ideal for supporting large structures and heavy equipment. Moreover, steel H-beams have a higher strength-to-weight ratio compared to materials like wood or concrete. This means that steel can withstand greater loads while being relatively lighter in weight, making it easier to transport and install. The strength of H-beams also allows for longer spans between support points, reducing the need for additional columns or supports, thus maximizing space utilization in a building. In addition to their superior strength, steel H-beams also offer exceptional durability and longevity. Steel resists corrosion, rot, and pests, which can be common issues with materials like wood. This durability ensures that structures built with steel H-beams can withstand harsh weather conditions and require minimal maintenance over their lifespan. Overall, steel H-beams surpass other building materials in terms of strength, offering unparalleled structural integrity, higher strength-to-weight ratio, and greater durability. These characteristics make them a preferred choice for a wide range of construction projects, from high-rise buildings and bridges to industrial facilities and warehouses.

Send your message to us

Hot Rolled H-Beam Structure Steel Q235 Good Price Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords