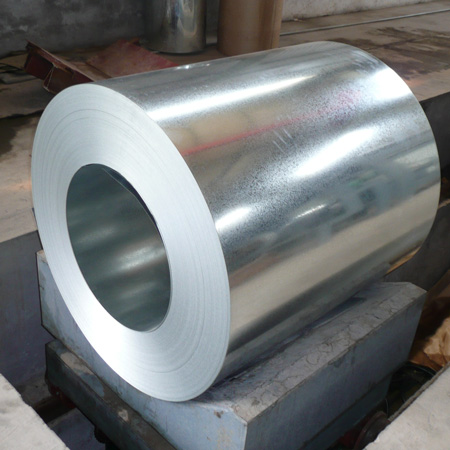

HQ Stainless Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

316L Stainless Steel Coil

1. Chemical composition of 316L Stainless Steel Coil

C | Si | Mn | P | S | Ni | Cr |

Max0.03 | max1.00 | max2.00 | max0.045 | max0.03 | 10.00-14.00 | 16.00-18.00 |

2. Mechanical properties of 316L Stainless Steel Coil

Yield Strength | Tensile | Elongation | Hardness (HV) | Hardness (HRB) |

≥175 | ≥480 | ≥40 | ≤200 | ≤90 |

3. Standard of 316L Stainless Steel Coil : AISI, ASTM, GB, EN, DIN, JIS

4. Surface of 316L Stainless Steel Coil : 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size of 316L Stainless Steel Coil :

Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ of 316L Stainless Steel Coil : 1 Ton

7. Payment terms of 316L Stainless Steel Coil : T/T or L/C

8. Packing of 316L Stainless Steel Coil : Seaworthy package with wooden or Iron pallets with the paper and the steel strip,

or as customers' request.

9. Delivery time of 316L Stainless Steel Coil : Usually about 7 days after we confirming the order, or according to your quantity.

If you have any question or demand, pls feel free to contact me.

- Q: Can stainless steel sheets be used for electrical conductivity?

- Typically, stainless steel sheets are not employed for electrical conductivity. Stainless steel is renowned for its exceptional resistance to corrosion and durability, rendering it apt for a diverse range of applications like kitchen appliances, construction materials, and industrial equipment. Nevertheless, stainless steel falls short in terms of conductivity compared to metals such as copper or aluminum. Consequently, materials with superior electrical conductivity properties are commonly preferred for electrical purposes.

- Q: Can stainless steel sheets be used for storage containers?

- Indeed, storage containers can be made from stainless steel sheets. Stainless steel, a sturdy and corrosion-resistant material, finds extensive use in diverse sectors such as food and beverage, pharmaceuticals, and chemical storage due to its ability to withstand high temperatures, resist rust and stains, and its non-reactive properties. These qualities make stainless steel an ideal choice for storage containers. By fabricating stainless steel sheets into containers of different sizes and shapes, a secure and hygienic storage solution can be achieved for a wide array of products. Moreover, stainless steel is effortless to clean and maintain, ensuring the longevity and cleanliness of the storage containers.

- Q: Stainless steel sheet welding method, thickness of 0.5mm

- Micro plasma arc welding, argon arc welding, laser welding, seam welding can be. It's not something that's hard to solder. Answer in detail. You need to know what you look like.

- Q: Are stainless steel sheets suitable for fire-rated applications?

- Yes, stainless steel sheets are suitable for fire-rated applications. Stainless steel is known for its high resistance to heat and fire, making it a reliable choice for fire-rated applications. It has a high melting point and does not easily deform or lose its structural integrity when exposed to high temperatures. Additionally, stainless steel does not combust or release toxic fumes when heated, which is crucial in fire-rated applications where safety is a top priority. Stainless steel sheets are commonly used in fire-resistant doors, walls, and other structural components to enhance fire resistance and protect against the spread of flames.

- Q: What are the different types of surface finishes available for stainless steel sheets?

- There are several types of surface finishes available for stainless steel sheets, including mill finishes, brushed finishes, mirror finishes, patterned finishes, and embossed finishes.

- Q: How do you polish stainless steel sheets?

- To polish stainless steel sheets, you can follow a few simple steps. First, ensure that the surface is clean and free from any dirt or debris. You can use a mild detergent or stainless steel cleaner to remove any stains or marks. Next, use a soft cloth or sponge to apply a stainless steel polish or a combination of vinegar and olive oil. Apply the polish in the direction of the grain, which is usually a linear pattern on the surface of stainless steel. Once the polish is applied, use another clean cloth to buff the surface in the same direction as the grain. Apply gentle pressure and continue buffing until the stainless steel sheets start to shine and appear polished. If necessary, repeat the process in areas that require additional polishing, and ensure that all excess polish is wiped away to avoid streaks or residue. It is important to note that different stainless steel finishes may require specific polishing techniques or products. Always refer to the manufacturer's instructions or guidelines for best results.

- Q: Lead and stainless steel plate welding together? How do you solder it?

- In addition, ultrasonic welding and ultrasonic welding are also a solid phase welding method with mechanical energy as energy source. Ultrasonic welding, welding workpiece in lower static pressure, issued by the sound of very high frequency vibration can make joint surface crack friction and heating to produce strong welding temperature and the formation of the combination. Ultrasonic welding can be used for welding between most metal materials, can realize metal, dissimilar metal and metal and nonmetal welding can be applied to the repetitive production of metal wire, foil or 2~3mm plate metal joint.

- Q: Are stainless steel sheets resistant to saltwater corrosion?

- Stainless steel sheets possess a high level of resistance against corrosion caused by saltwater. The exceptional corrosion resistance of stainless steel is widely recognized, rendering it an ideal material for use in environments exposed to saltwater. The presence of chromium in stainless steel results in the formation of a protective oxide layer on the surface, effectively acting as a barrier against corrosion. This oxide layer serves to shield the steel from direct contact with saltwater, thus minimizing the risk of corrosion. Moreover, stainless steel grades such as 316 and 316L are specifically engineered to provide enhanced resistance against saltwater corrosion, further increasing their suitability for marine applications. In conclusion, the outstanding corrosion resistance properties of stainless steel sheets make them a dependable option for saltwater environments.

- Q: How do I prevent fretting corrosion on stainless steel sheets?

- To prevent fretting corrosion on stainless steel sheets, there are several preventive measures that can be taken: 1. It is crucial to handle stainless steel sheets properly, avoiding any scratching or rubbing of the surface that could lead to fretting corrosion. Gloves should be worn and contact with other metals or rough surfaces should be avoided. 2. Regular cleaning of the stainless steel sheets using mild detergents or specialized stainless steel cleaners is recommended. This helps to remove contaminants that can initiate corrosion and prevents the build-up of dirt or grime that can contribute to fretting corrosion. 3. Applying a suitable lubricant or anti-seize compound on the contact surfaces can minimize friction and prevent fretting corrosion, especially in applications with repeated movement or vibration. 4. Whenever possible, it is advised to isolate stainless steel sheets from direct contact with other metals. This can be achieved by using insulating materials, gaskets, or non-metallic spacers to create a barrier between the stainless steel and potentially corrosive materials. 5. Regular inspection of the stainless steel sheets is important to detect any signs of fretting corrosion, such as small cracks, discoloration, or pitting. Early detection allows for prompt action to prevent further damage. 6. Applying a protective coating, such as a passivation treatment or a corrosion-resistant paint, can provide an additional layer of protection against fretting corrosion. It is recommended to consult with a professional to determine the most suitable coating for the specific application. 7. Proper storage of stainless steel sheets is essential. When not in use, they should be stored in a clean, dry environment to minimize exposure to moisture or corrosive substances. The storage area should be well-ventilated and free from any contaminants that could potentially initiate fretting corrosion. By following these preventive measures, the risk of fretting corrosion on stainless steel sheets can be significantly reduced, ultimately prolonging their lifespan.

- Q: Are stainless steel sheets suitable for aerospace applications?

- Stainless steel sheets are well-suited for aerospace applications. This material, known for its versatility and durability, possesses outstanding strength-to-weight ratio, corrosion resistance, and high-temperature resistance. Consequently, it is highly valued within the aerospace industry due to its ability to endure extreme conditions while maintaining structural integrity. Its wide utilization in aircraft structures, engine components, and fuel systems is a testament to its reliability. Furthermore, stainless steel sheets are easily molded, welded, and fabricated, allowing for tailored engineering and precise customization in aerospace applications. Moreover, their resistance to fatigue and erosion ensures their dependability in components that experience constant stress and severe environments. In summary, stainless steel sheets possess the essential qualities necessary to meet the demanding requirements of the aerospace industry, making them an appropriate choice for a variety of applications.

Send your message to us

HQ Stainless Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords