Roof Sheet Galvanized Treatment Steel Coils

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

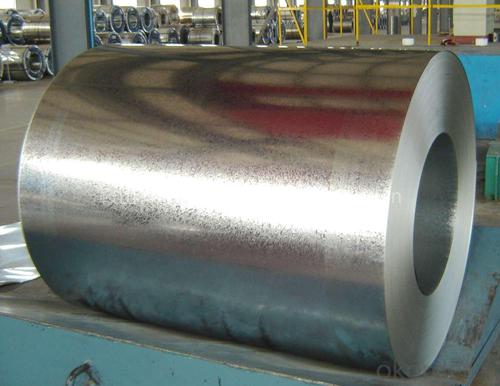

Roof Sheet Galvanized Treatment Steel Coils

Main structure of Roof Sheet Galvanized Treatment Steel Coils

1.Thickness:0.14-2.5mm

2.Width:600-1250mm

3.Grade:SGCC,JISG3302,DX51D,Q235

4.Zinc Coating:60-275g/m2

5.Coil ID:508mm/610mm

6.Coil weight:3-8ton

Specification for Roof Sheet Galvanized Treatment Steel Coils:

| Techinical Standard: | JIS 3302 / ASTM A653 / EN10143 |

| Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

| Types: | Commercial / Drawing / Deep Drawing / Structural quality |

| Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.12-2.5mm (0.14-0.5mm is the most advantage thickness) |

| Type of coating: | galvanized |

| Zinc coating | Z60-275g/m2 |

| Surface treament | chromed / skinpass/ oiled/slightly oiled/ dry/ anti-fingerprint |

| Surface structure: | zero spangle / minimized spangle / regular spangle/ big spangle |

| ID coil | 508mm or 610mm |

| Coil weight | 3-8 MT per coil |

| Package: | Properly packed for ocean freight exportation in 20'containers |

| Application: | Industrial panels, roofing and siding for painting |

| Price terms | FOB,CFR,CIF |

| Payment terms | T/T L/C |

| delivery time | 25 days after recepit of deposit |

Application of Roof Sheet Galvanized Treatment Steel Coils

Industrial Panels

Building Construction

Roofing and Siding for Painting

Storage Steel Silo

Picture:

- Q: i have a question on a test and the questions before it are about blast furnace, wrought iron and cast iron...question 16 is..What is Steel?i dont really get what im being asked.. there could be many answers, what answer are they looking for?

- as steel is an alloy i thinkl they are looking for what elements it is made up of

- Q: What are the common applications of stainless steel coils?

- Stainless steel coils have numerous applications in various industries due to their exceptional corrosion resistance, durability, and versatility. Some common applications include manufacturing of kitchen appliances, automotive parts, construction materials, medical instruments, chemical processing equipment, and electrical components. Additionally, stainless steel coils are widely used in the production of pipes, tubes, and fittings for various sectors such as oil and gas, food processing, pharmaceuticals, and water treatment.

- Q: What are the different methods of painting steel coils?

- There are several methods of painting steel coils, including coil coating, spray painting, and powder coating. Coil coating involves applying a liquid coating to the surface of the steel coil, which is then cured and dried. Spray painting involves using a spray gun to apply paint to the coil, typically in multiple layers. Powder coating involves electrostatically applying a dry powder to the coil, which is then cured and fused onto the surface. Each method has its advantages and is chosen based on factors such as durability, cost, and desired finish.

- Q: What are the common defects in steel coil surface finishes?

- Common defects in steel coil surface finishes can include scratches, pits, rust, oil stains, and uneven coating. Scratches can occur during handling and transportation, and they can affect the overall appearance and performance of the steel coil. Pits are small depressions on the surface caused by a variety of factors such as impurities in the steel or improper processing. Rust can form when the steel coil is exposed to moisture or corrosive environments, and it can weaken the structural integrity of the material. Oil stains can occur if the coil is not properly cleaned before or after processing, leaving unsightly marks on the surface. Uneven coating can happen during the application of protective coatings or paints, resulting in areas with different levels of protection and aesthetics. It is important to address these defects to ensure the quality and durability of the steel coil for its intended applications.

- Q: How do steel coils contribute to the automotive industry?

- Steel coils are a crucial component in the automotive industry as they are used to manufacture various parts of vehicles, including the body frame, doors, hoods, and chassis. The high strength and durability of steel coils make them ideal for enhancing the safety, structural integrity, and overall performance of automobiles. Additionally, steel coils are cost-effective, readily available, and can be easily formed into different shapes and sizes, making them an essential material in the production of cars and trucks.

- Q: How does adding carbon to Iron make it stronger? How does steel look the molecular structure in comparison to Iron? looking for a very scientific answer =]

- Cast Iron' is typically brittle, while 'Maleable Iron' has a small percentage of carbon which allows it to be hammered and formed. Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron. Steel is a crystalline structure of iron molecules interspersed with carbon molecules. This is properly known as cementite. The hardness and malleability of steel depends not only on the carbon content, but on how the carbon and iron molecules are arranged to one another. Internal stresses in the steel's crystalline structure will increase or decrease depending on the temperature it is subjected to and the rate at which molten steel is cooled. This 'tempering' can increase the strength of the steel at the expense of brittleness.

- Q: I bought a Remington 870 super mag last fall and wanted to to switch to non-tox steel loads. The gun came with a modified rem choke. I know that not all chokes are qualified to handle steel. It doesn't say anywhere on the choke no steel I was just wondering if anyone out there knew for sure that those chokes that the guns come with won't get damaged be steel.

- No problem. With steel shot you would use one choke size LARGER. If you want a full choke type pattern ( 70 % in a 30 inch circle at 30 yards ) you use a modified choke. if you want a modified pattern use the improved cylinder. Don't use the full or extra full. This is because when using lead shot it deforms, and fits through the choke, steel shot does not deform, it remains rigid. The first indication of a problem will be a slight bulge in the barrel right behind the choke. Check that once in a while, if you ever have that problem, it is not drastic if caught early. Today's modern shotguns all have been set up for steel shot. The old ones such as Belgium Brownings, are a no go. Funny thing, when we first began importing steel shot, I asked a Browning Tech guy if he thought I could fire steel out of my Belgium Browning. He said not a good idea, however, if you have the Citori or other Japanese made Brownings, no problem. Hummm, my expensive Brownings, no, but Japanese made OK, this is because the Japanese steel was higher quality. Geeeze. I was shocked.

- Q: How are steel coils used in the production of automotive engine components?

- Steel coils are used in the production of automotive engine components by being processed and shaped into various parts, such as pistons, crankshafts, and connecting rods. The coils are first cut, stamped, and formed into the desired shapes, and then undergo heat treatment and other machining processes to enhance their strength and durability. These components are crucial for the proper functioning of an automotive engine, as they provide structural support and help convert the energy generated by the combustion process into mechanical motion.

- Q: How are steel coils used in the production of consumer goods?

- Steel coils are used in the production of consumer goods as they are processed and shaped into various components, such as sheets, tubes, and wires. These components are then utilized in manufacturing a wide range of products, including automobiles, appliances, furniture, and construction materials. The high strength and durability of steel make it an ideal material for consumer goods, ensuring their longevity and performance.

- Q: My teacher says if they were that they would still be standing today. I'm not sure if he means the reinforced steel in the concrete beams, columns etc or if the whole beams and columns floor etc were were made of reinforced steel.

- There is no way you could make a 110 floor building out of concrete.

Send your message to us

Roof Sheet Galvanized Treatment Steel Coils

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords