Color Galvanized Steel Coil for Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:CGCC, SGCC, DX51D, DX51D+Z, TDC51D, TDC51D+Z, G550

Standard:ASTM, JIS, GB, AISI, DIN, BS

Steel Grade:Q195

Certification:ISO, SGS, BV

Surface Treatment:Coated

Technique:Cold Rolled

Thickness:0.12-1.5mm

Width:600-1500mm

Color:as The Ral Color or Sample

Painting Thickness:Top 15-25um+Back 8-10um

Raw Material:Galvalume Steel Coil or Galvanized

Zinc-Coating:30-275G/M2

Delivery Time:15-30 Days

Production Ability:30000 Mt/Month

Port:Qingdao

Export Markets:Global

Additional Info.

Packing:Standard Seaworthy Packing

Standard:JIS G3302-1998/EN10142/ASTM

Origin:China

HS Code:72107010

Production Capacity:400000ton Per Year

Product Description:

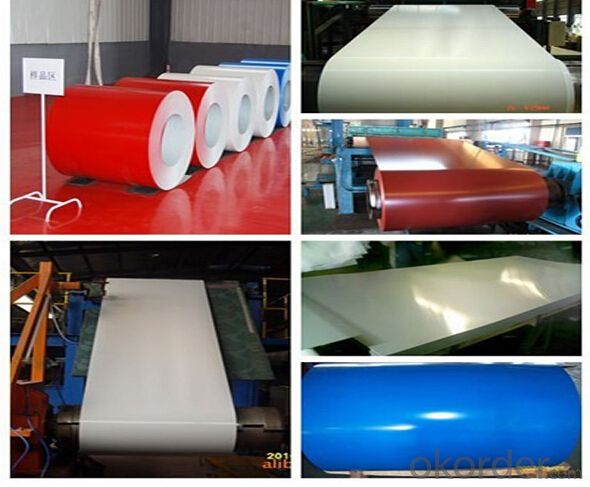

NAME: color galvanized steel for roofing sheet

SIZE:

Thickness: 0.12-1.5mm

Width: 600mm,750mm,762mm,900mm,914mm,940mm,1000mm,1050mm, 1090mm,1100mm,1200mm, 1219mm, 1250mm,1250mm

Length: According to the customer's request

Hardness:Soft( around HRB 65) ,full hard (HRB90-95)

Strength of Extension: more than 300Mpa

Yield Strength:370-380Mpa

Thickness tolerance: +/-0.02 mm(0.01 As you requested)

Width tolerance:+/ -2.0mm

ZINC, PAINT & COLOR:

Zinc coating: 30-275G/M2

Paint thickness: Top 15-25um + Back 8-10um

Paint: Epoxy Polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester

Color: As the RAL color standard or customer's sample

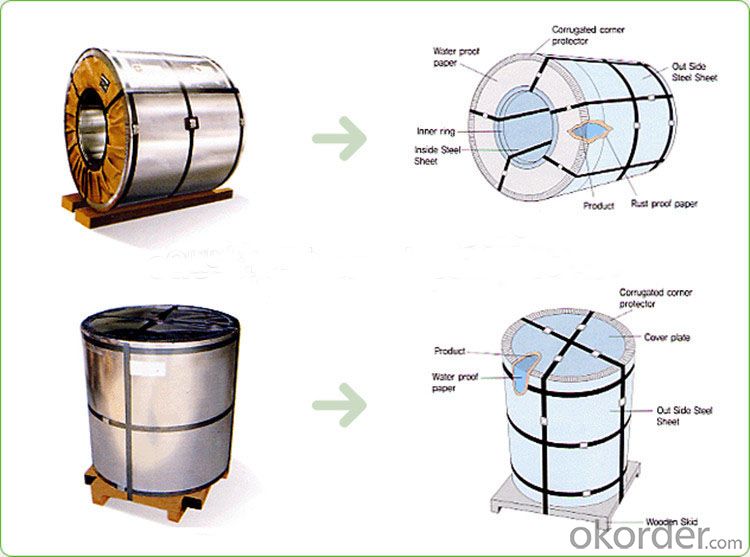

PACKING:

Coil weight: 3-5tons

ID: 508mm\610mm

Standard sea worthy package

STANDARD:

JIS G3302-1998/EN10142/ASTM A653/ASTM A792/ AISI/BS/ DIN/GB

Base mental: Hot galvanized steel,SGCC,SPCC,SPHC, DX51D+Z, Q195,etc

Quality: CQ,DQ,DX51D

Lifespan: 10-15 years

APPLICATION:

Specification:

Base mental | hot galvanized steel |

| Thickness | 0.12-1.5mm |

| Width | 600-1500mm |

| Coil Weight | 3-5ton |

| Quality: | DX51D DQ CQ |

| Color | all RAL colors or as per customers' sample |

| Zinc-coating | 30g/m2-275g/m2 |

| Coil ID | 508mm-610mm |

| Packing | standard seaworthy package |

| Technique | cold rolled, hot-dipped galvanizing, color coated |

| Painting | Top and bottom: 15-25mic RMP Back: 8-10mic |

| Tolerance | Thickness: +/-0.02mm Width: +/-2mm |

| Description | Pre-painted Steel Coil uses hot galvanized steel as its basic material, factory adopts advanced equipment to degrease, rinse, transform the galvanized steel, then make primary and refined lavation to the steel coils. |

| application | They are mainly applied for steel structure buildings, household appliance, furniture, transportation and other industries |

| feature | Pre-painted Steel Coils have excellent performance of decoration, corrosion resistance etc. |

| The special order can be negotiated | |

Product and Package:

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: How are steel coils tested for mechanical properties?

- Steel coils are tested for mechanical properties through various methods, including tensile testing, hardness testing, and impact testing. Tensile testing involves stretching the steel coil until it breaks to determine its strength, elasticity, and ductility. Hardness testing measures the resistance of the steel to indentation or scratching, indicating its overall toughness. Impact testing involves striking the coil with a pendulum to assess its ability to absorb energy without fracturing. These tests help evaluate the quality and performance of steel coils in different applications.

- Q: i'm looking into pedal steel guitars, and I would like some suggestions or links and info on what kind i should get.

- Try okorder -The Art of Steel Guitar/ Steel guitar players -Take it away Leon- McAuliffe and 'Speedy West' were a couple greats. In the late '50s, Speedy was playing a Fender 1000 Pedal steel. He often did duets with Jimmy Bryant The Fastest Guitar Player In The Country! / note also the 'Emmons Guitar Company':

- Q: i was thinking like getting a a steel building for 2 or 3 stall does anyone know how much that would cost? Have anyone used steel building how do you like them etc

- a great style of human beings are putting up those steel homes made by making use of agencies like Cleary or Morton because of the fact they are greater fee effective. yet in my opinion, i don't think of they greater wholesome horses all right. They dent very relatively, all the horse has to do is lean against it somewhat. additionally they provide no insulation so as that they are like little ovens interior the summertime and are fairly chilly interior the wintry climate. in case you're able to have adequate money it, i might flow with a competent previous formed timber barn.

- Q: How are steel coils inspected for color consistency using colorimetry?

- Steel coils can be inspected for color consistency using colorimetry by measuring the color of the surface using a spectrophotometer. This device analyzes the reflected light and provides objective and precise color data. By comparing the color measurements of different areas of the coil, any variations in color consistency can be identified, allowing for quality control and ensuring the desired color uniformity throughout the coil.

- Q: What are the different types of steel coil coatings for heat resistance?

- Heat resistance is achieved through the use of different types of steel coil coatings. These coatings are designed specifically to safeguard the steel surface, preventing it from deteriorating or oxidizing under high temperatures. Organic coatings, such as epoxy, polyester, or polyurethane, are commonly used. They form a protective barrier against heat and prevent the steel from corroding or oxidizing. Organic coatings are typically employed in situations where moderate heat resistance is necessary. Another option is inorganic coatings, made from ceramic or metallic materials. These coatings offer excellent heat resistance and can endure extremely high temperatures. Industries like automotive, aerospace, and power generation frequently utilize inorganic coatings, as their components are exposed to intense heat. Specialized coatings are also available to meet specific heat resistance requirements. Silicone coatings, for instance, exhibit exceptional heat resistance and can withstand temperatures reaching 600°C (1112°F). They find common use in applications like exhaust systems, ovens, and industrial furnaces. Some steel coil coatings may also incorporate additives or fillers to enhance their heat resistance properties. These additions improve the coating's ability to withstand high temperatures and provide superior protection against heat-related issues. In conclusion, a range of steel coil coatings is available for heat resistance, including organic coatings, inorganic coatings, and specialized coatings. The choice of coating depends on the specific heat resistance requirements of the application. Factors such as temperature range, duration of exposure, and environmental conditions must be taken into account when selecting the appropriate coating.

- Q: Can steel coils be reused?

- Yes, steel coils can be reused. Steel is a highly recyclable material, and steel coils can be melted down and used to produce new steel products. Recycling steel coils not only helps to conserve resources and reduce waste but also contributes to a more sustainable and environmentally-friendly manufacturing process.

- Q: How are steel coils coated to prevent corrosion?

- Steel coils are coated to prevent corrosion through a process known as galvanization. This involves applying a protective layer of zinc onto the surface of the steel coils. The zinc acts as a barrier, preventing the steel from coming into contact with moisture and oxygen, which are the main causes of corrosion. This coating not only provides excellent corrosion resistance but also enhances the durability and longevity of the steel coils.

- Q: I have heard of Cold Rolled steel, Castle Forged steel and Valerian steel and i was just wondering the difference between them.I know Valerian steel is by far the strongest and durable but what about the other two types? Do you know because i haven't read all the books yet.

- Cold rolled steel is referring to rolled steel. It is referring to weapons made from rolled steel that is unrolled and stamped out. In real-life, rolled steel isn't nearly as strong as steel that is cast and forged. Think of a cheap dinner fork that you can easily bend and a nice dinner fork you can't bend at all. The cheap fork is stamp-pressed out of rolled steel and the nice fork is cast. In Game of Thrones, cold rolled steel is crap, but it's cheep and common. Castle forged steel is the best most people have available, much higher quality than cold rolled steel. Presumably it's forged in the castles of Westeros, including King's Landing. Valerian steel is special, rare steel that was anciently forged that is stronger than any other steel. They no longer make Valerian steel since the fall of Valeria. As such, the only Valerian steel available is by getting it from things already made. In real-life, it might be comparable to the extremely high quality steels forged into ancient katanas, ninja fighting swords from Japan. The Lanisters took a sword made of Valerian steel that had been passed down to Ned Stark and had it melted down, recast, then forged into two smaller swords.

- Q: How are steel coils used in the manufacturing of automotive exhaust systems?

- Steel coils are used in the manufacturing of automotive exhaust systems as they are formed into specific shapes and sizes to create the necessary components, such as pipes, mufflers, and catalytic converters. The coils are precision-cut, welded, and bent to fit the design requirements and ensure efficient exhaust flow, durability, and resistance to high temperatures and corrosion.

- Q: Are steel coils used in the oil and gas industry?

- Yes, steel coils are commonly used in the oil and gas industry for various applications. They are utilized in the manufacturing of pipelines, storage tanks, and other equipment due to their strength, durability, and resistance to corrosion. Steel coils are also employed in the construction of offshore platforms and drilling rigs, where they provide structural support and ensure the safety and reliability of the infrastructure.

Send your message to us

Color Galvanized Steel Coil for Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords