Structural Steel H-beam JIS Standard all Kinds of Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Structural Steel H-beam JIS Standard at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Product Advantages:

OKorder's Structural Steel H-beam JIS Standard are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

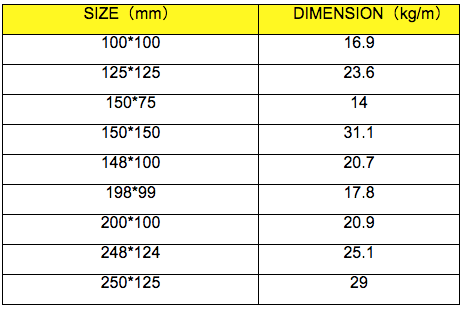

Product Specifications:

Specifications of Hot Rolled Structural Steel H Beam

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: What are the different types of welding used for steel H-beams?

- There are several types of welding commonly used for steel H-beams, including shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), and submerged arc welding (SAW). Each of these methods has its advantages and is chosen based on factors such as the thickness of the steel, the desired strength, and the specific application requirements.

- Q: What are the different methods of lifting and installing steel H-beams?

- There are several methods of lifting and installing steel H-beams, depending on the specific requirements of the project and the available equipment. Some of the common methods include: 1. Crane: The most common and widely used method is using a crane to lift and install H-beams. Cranes come in various sizes and capacities, allowing for efficient and precise placement of beams at the desired location. Depending on the size and weight of the H-beam, different types of cranes such as mobile cranes or tower cranes may be used. 2. Forklift or telehandler: For smaller and lighter H-beams, a forklift or telehandler may be utilized. These machines have forks or lifting attachments that can be adjusted to fit the width of the beam. They provide a versatile and cost-effective solution for lifting and installing beams in tight spaces or on uneven terrain. 3. Hydraulic jacking system: In situations where there is limited access or overhead clearance, a hydraulic jacking system can be employed. This method involves lifting the beam incrementally using hydraulic jacks and inserting shims or temporary supports until the desired height is reached. The process is repeated until the beam is properly installed. 4. Skidding or rolling: This method is suitable for long H-beams or when a crane is not available. It involves using rollers or skids to gradually move the beam horizontally into position. This method requires careful planning and precise coordination to ensure the beam is aligned properly during the installation process. 5. Welding or bolting: Once the H-beams are lifted and in position, they need to be secured to the supporting structure. This can be achieved through welding or bolting, depending on the structural requirements and design specifications. Welding is a permanent method that provides a strong connection, while bolting allows for easy disassembly if required. It is important to note that proper safety measures should be followed during the lifting and installation of steel H-beams. This includes ensuring the equipment is in good working condition, using appropriate slings, chains, or lifting devices, and adhering to relevant safety guidelines and regulations. Additionally, the specific method chosen will depend on factors such as the size and weight of the H-beams, site conditions, and project constraints.

- Q: Can steel H-beams be used for supporting elevated walkways or platforms?

- Indeed, elevated walkways or platforms can be supported by steel H-beams. In construction, steel H-beams are frequently employed due to their robustness and endurance. Their exceptional load-bearing capacities make them well-suited for sustaining structures like walkways and platforms. The H-shaped configuration of these beams enables superior weight distribution and resistance against bending or twisting forces, guaranteeing stability and safety for elevated constructions. Moreover, steel H-beams can be conveniently fabricated and installed, rendering them a pragmatic selection for such purposes.

- Q: How do steel H-beams contribute to energy-efficient building designs?

- The numerous benefits of steel H-beams make them crucial components in energy-efficient building designs. Firstly, their high strength-to-weight ratio allows them to support heavy loads while minimizing the steel required. This reduces the overall weight of the building's structure and foundation, resulting in energy savings during construction, transportation, and installation. Moreover, H-beams provide excellent structural integrity, ensuring the stability and durability of the building. They resist bending and twisting forces, allowing for the construction of larger spaces without excessive support columns or walls. The open web design of H-beams also facilitates the installation of insulation materials, enhancing thermal efficiency and reducing energy consumption for heating and cooling. Additionally, H-beams can be easily fabricated and customized to fit specific architectural designs. This enables architects to optimize the building's layout for natural lighting and ventilation. By incorporating large windows, skylights, and open spaces, energy-efficient buildings can maximize natural daylight and reduce the need for artificial lighting. Similarly, proper ventilation systems can be integrated, utilizing natural airflows to cool the building and decrease reliance on energy-intensive air conditioning. Furthermore, steel H-beams possess excellent fire resistance properties, critical for energy-efficient buildings. They withstand high temperatures and prevent fire spread, enhancing occupant safety and reducing the risk of structural damage. Consequently, the need for fireproofing measures, such as additional insulation or sprinkler systems, can be minimized, saving energy and resources in the long run. In conclusion, steel H-beams significantly contribute to energy-efficient building designs through their high strength-to-weight ratio, structural integrity, thermal efficiency, and versatility in design. Their fire resistance properties further enhance the safety and sustainability of these structures. By utilizing H-beams, architects and builders can create environmentally-friendly structures that promote energy conservation, reduce greenhouse gas emissions, and contribute to a more sustainable future.

- Q: What are the different methods of reinforcing steel H-beams?

- Different methods are available to reinforce steel H-beams, which are commonly used in construction to provide structural support. These methods aim to improve the strength, durability, and load-bearing capacity of H-beams, ensuring their optimal performance in various applications. 1. Welding: Welding is a widely used method to strengthen steel H-beams. By welding two or more H-beams together, a stronger and more rigid structure is created. This is achieved by melting the edges of the beams and fusing them together using heat and pressure. Welding can also be employed to attach additional steel plates or angles to the H-beam, further enhancing its overall structure. 2. Shear Connectors: Shear connectors are effective in reinforcing H-beams, especially in composite construction. These connectors, typically steel studs or bars, are welded onto the top flange of the H-beam. Their purpose is to transfer shear forces between the concrete slab and the steel beam, thereby improving the structural integrity and load-carrying capacity of the H-beam. 3. Steel Plates: Steel plates are commonly used to reinforce H-beams, particularly when dealing with heavy loads or long spans. These plates are usually bolted or welded to the web or flanges of the H-beam, providing additional strength and stiffness. The size and thickness of the steel plates can be customized based on the specific project requirements. 4. Composite Beams: Composite beams involve combining a steel H-beam with a concrete slab. This method entails placing the concrete slab on top of the H-beam and connecting them together using shear connectors like steel studs or bars. Composite beams offer numerous advantages, including increased load-carrying capacity, improved fire resistance, and enhanced overall stiffness. 5. Reinforced Concrete Encasement: Reinforcing H-beams through reinforced concrete encasement is another method. This technique involves wrapping the H-beam with reinforced concrete, which is achieved by constructing formwork around the beam and pouring concrete into it. The concrete encasement enhances the strength and stiffness of the H-beam, providing additional resistance against bending, shear, and other forces. It is important to note that the choice of reinforcing method depends on specific project requirements, such as load requirements, span length, construction constraints, and design considerations. Consulting with a structural engineer or construction professional is highly recommended to determine the most suitable method for reinforcing steel H-beams in a given application.

- Q: What are the different types of steel H-beam connections used in bridge design?

- There are several different types of steel H-beam connections commonly used in bridge design. These connections are crucial in ensuring the stability and integrity of the bridge structure. Some of the most commonly used types of steel H-beam connections in bridge design include: 1. Welded Connections: This is the most common type of connection used in bridge design. Welded connections involve joining the H-beams together by melting and fusing the materials. Welded connections provide excellent strength and rigidity, making them suitable for various bridge types. 2. Bolted Connections: Bolted connections involve using high-strength bolts to connect the H-beams. These connections are relatively easy to install and provide flexibility for disassembly and maintenance. However, bolted connections may not offer the same strength and rigidity as welded connections. 3. Riveted Connections: Riveted connections were commonly used in older bridge designs but are rarely used in modern construction. Riveted connections involve using steel rivets to join the H-beams. While riveted connections provide good strength and durability, they can be time-consuming and expensive to install compared to other connection methods. 4. Moment Connections: Moment connections are used in situations where there is a need to transfer bending moments between the H-beams. These connections provide a high level of rigidity and are often used in bridge designs where large loads or forces are anticipated. 5. Shear Connections: Shear connections are designed to transfer shear forces between the H-beams. These connections are crucial in ensuring the stability and integrity of the bridge structure, particularly in areas where there is a significant horizontal force. 6. Composite Connections: Composite connections involve the combination of steel H-beams with other materials, such as concrete or timber. These connections provide the benefits of both materials, with the steel providing strength and the additional material offering other desirable properties like fire resistance or aesthetics. Overall, the choice of steel H-beam connection type depends on various factors, including the bridge design, load requirements, and construction methods. Each connection type has its own advantages and limitations, and the selection should be based on the specific needs and considerations of the bridge project.

- Q: What does "welding H" steel set "vertical" and "corrective processing" mean?

- Since the H steel web needs to be machined is 10 thick, it can be easily welded to the submerged welding machine, so there is no need to break the seamAfter blanking, use the crane to lift the plate to the erection machine one by one, and clamp. Start the set, set the machine, adjust the position of the three plates, and fix the spot weldingNote: the assembling machine is specially used to assemble the H steel machine, three plates, processing it can clamp type H steel H steel will start the machine, by the end of the assembling machine to roll to the other end, through assembling the machine when the door frame, can be used to adjust the assembling machine accurate three plate position, is a period of adjustment of rolling.After erection, the crane is welded to the welding platform and submerged arc weldingAfter welding, lift to straightening machine for straightening and correctingNote: the straightening effect correction principle: after welding flange may be not perpendicular to the web, using roller flat. Because H type steel may also be in the length direction is not straight, also can use the pressure roller is adjusted. The general steel processing plant of the straightening machine only in H flat slab steel width flat with length up straight. Straight up the length function of flame correction, flame correction, H steel with roasted curved, roasted red with water, due to thermal expansion and contraction, H type steel straight up. But it must have some experience to master the operation.

- Q: How do you connect steel H-beams together?

- Steel H-beams can be connected together in several ways depending on the specific application and load requirements. Here are some common methods for connecting steel H-beams: 1. Welding: Welding is a popular method for connecting steel H-beams. It involves melting the adjacent surfaces of the beams using high heat and then allowing them to cool and solidify, creating a strong bond. Welding provides excellent strength and stiffness, making it suitable for heavy-duty applications. However, it requires skilled welders and can be time-consuming. 2. Bolting: Bolting is another commonly used method for connecting steel H-beams. It involves drilling holes through the flanges or webs of the beams and then using bolts and nuts to secure them together. Bolting offers flexibility, as it allows for easy disassembly and reassembly if necessary. However, it may not provide the same level of strength as welding, especially in applications with high loads. 3. Riveting: Riveting is an older method that involves using metal pins or rivets to connect the steel H-beams. It works by inserting the pins or rivets through pre-drilled holes and then deforming the ends to secure them in place. Riveting can provide good strength, but it is not as common as welding or bolting due to the complexity and time required for installation. 4. Adhesive bonding: In some cases, adhesive bonding can be used to connect steel H-beams. This method involves applying a strong adhesive between the contacting surfaces of the beams and allowing it to cure. Adhesive bonding can provide high strength and stiffness, but it requires careful surface preparation and may not be suitable for all applications. It is important to consider the specific requirements of the project and consult with structural engineers or professionals to determine the most appropriate method for connecting steel H-beams. Additionally, local building codes and regulations may dictate specific requirements for beam connections.

- Q: What does "H400*250*8*12" mean in steel structures?

- A direct consequence of low industrial concentration is caused by excessive competition, in 2005, the average profit of 5% steel enterprises, in addition, steel tube truss and complicated structure, difficult construction of landmark projects to higher profit margins, as building light steel portal frame, due to intense competition, the profit space is generally low, so only there are some enterprises in order to steal frugal material bidding, so only the sensation of three-dimensional "white paper". But the good news is the processing capacity of 13 million 510 thousand tons of steel structure steel structure association in 2005 statistics, the processing capacity of the top five steel enterprises has more than 1 million tons, the annual top ten enterprises the basic processing capacity in more than 100 thousand tons.

- Q: How do steel H-beams perform in terms of seismic resistance?

- Steel H-beams are widely acknowledged for their exceptional ability to withstand seismic forces. The distinctive structural design of H-beams, comprising a horizontal web connected to two vertical flanges, offers several advantages in this regard. To begin with, the shape of H-beams allows for more efficient distribution of seismic loads compared to other structural elements. The flanges positioned at the top and bottom of the beam provide enhanced resistance against bending and torsion forces. This design minimizes structural damage and deformation during earthquakes. Additionally, steel H-beams possess high strength and stiffness properties, making them highly suitable for seismic resistance. The use of steel as a construction material provides superior tensile strength, enabling the beams to effectively absorb and dissipate seismic energy. The high strength-to-weight ratio of steel H-beams ensures structural stability and resistance against lateral forces induced by earthquakes. Moreover, steel H-beams exhibit excellent ductility, meaning they can undergo significant deformation without failing. This flexibility and energy absorption capacity help to reduce the overall impact of seismic activity on the structure. The ductility characteristic also allows the H-beams to redistribute forces and stresses, preventing localized damage and promoting overall structural resilience. Furthermore, various techniques can be employed in the design and construction of steel H-beams to enhance their seismic performance. Advanced connection systems, such as moment-resisting connections, can be utilized to ensure the beams maintain their strength and integrity during seismic events. These connection systems facilitate controlled yielding and energy dissipation, further improving the overall seismic resistance of the H-beam structure. In conclusion, the efficient load distribution, high strength, stiffness, and ductility properties of steel H-beams contribute to their excellent seismic resistance. Their ability to withstand seismic forces makes them a popular choice in regions prone to earthquakes, guaranteeing the safety and stability of structures during such events.

Send your message to us

Structural Steel H-beam JIS Standard all Kinds of Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords