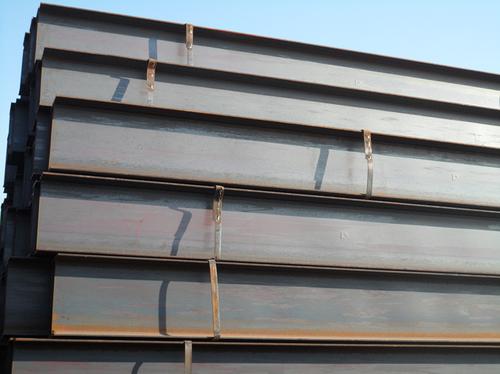

Hot Rolled JIS Standard H Beams

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled JIS Standard H Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled JIS Standard H Beams are ideal for structural applications and are widely used inindustrial plants, civil construction, municipal works, oil platforms, bridges, flatbed beams, electrified railway power stand, railway bridges and other light steel structure, super-light H-beam is ideal for containers, mobile homes , all kinds of garage, box-type trains, electrical bracket, various venues, small villa manufacturing etc.

Product Advantages:

OKorder's Hot Rolled JIS Standard H Beams are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Trademark | Rank | Chemical composition (quality score) % | |||||

C | Si | Mn | S | P | |||

≤ | ≤ | ≤ | |||||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | |||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | |||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | ||||||

≤16 | 16-40 | ≤16 | 16-40 | ||||

≥ | ≥ | ||||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: How are steel H-beams different from other types of beams?

- H-sections, also called Steel H-beams, possess distinct qualities and shape that set them apart from other beams. Their specific cross-sectional shape, resembling the letter "H," grants them significant advantages over alternative beam types. To begin with, the shape of the H-beam allows it to bear a greater load compared to beams of similar weight. This is due to the even weight distribution along its length, maximizing its ability to withstand heavy loads. Consequently, H-beams find extensive use in construction projects that demand robust and enduring structural support, such as high-rise buildings, bridges, and industrial facilities. Moreover, H-beams provide enhanced structural stability. The flanges, which are the top and bottom horizontal sections of the H-beam, offer resistance against bending and twisting forces. This characteristic makes H-beams less prone to deformations and enables them to maintain their shape under heavy loads. Additionally, the web, or vertical section of the H-beam, offers supplementary support and rigidity, ensuring overall stability in the structure. Another notable advantage of H-beams lies in their versatility. With their inherent strength and stability, H-beams can span longer distances without requiring intermediate supports. This enables the creation of larger open spaces and more flexible architectural designs. Furthermore, H-beams can be easily welded together, allowing for the creation of longer beams and expanding their range of applications. Lastly, H-beams offer cost-effectiveness. Despite their robustness, H-beams are comparatively lightweight in relation to their load-bearing capacity. This reduces transportation costs and simplifies the installation process, making them a cost-effective option for construction projects. In conclusion, Steel H-beams stand out from other beam types due to their unique cross-sectional shape. This shape provides advantages in terms of increased load-bearing capacity, structural stability, versatility, and cost-effectiveness. These characteristics make H-beams the preferred choice for various construction applications where strength, durability, and efficiency are crucial factors.

- Q: What is the maximum load capacity of steel H-beams?

- The maximum load capacity of steel H-beams can be subject to variations based on several factors, including the beam's size, shape, and grade, as well as the span and support conditions of the particular application. Steel H-beams are specifically engineered to endure substantial loads, making them prevalent in construction and structural engineering endeavors. To ascertain the precise maximum load capacity for a particular steel H-beam, it is imperative to seek advice from engineering experts or consult structural design guidelines and load tables supplied by manufacturers.

- Q: How do steel H-beams perform in terms of fire resistance?

- Steel H-beams exhibit excellent fire resistance capabilities. With their unique composition and structural design, they possess a high melting point and are less susceptible to deformation or collapse when exposed to extreme temperatures. Consequently, they exhibit exceptional durability and maintain their structural integrity for extended periods during fire incidents. To further enhance their fire resistance, fireproofing materials such as intumescent coatings or fire-resistant insulation are applied to steel H-beams. These materials form a protective layer on the beam's surface, which expands upon exposure to heat, creating an insulating barrier. This barrier effectively retards the transfer of heat to the steel, thereby augmenting its fire resistance and preventing premature failure. Moreover, steel H-beams boast remarkable load-bearing capacities, even in elevated temperatures. Consequently, they continue to support the weight of the structure in the event of a fire, averting catastrophic collapses. This feature is particularly crucial in buildings and structures where fire safety is of paramount importance, such as high-rise buildings, industrial facilities, and infrastructure projects. It is important to note that despite their commendable fire resistance, steel H-beams are not entirely fireproof. In exceptionally high-temperature conditions, such as those encountered in intense fires, the steel may eventually weaken and lose its load-bearing capacity. However, when compared to other construction materials, steel H-beams offer superior fire resistance, making them a favored choice in projects prioritizing fire safety.

- Q: Can steel H-beams be used for solar panel supports?

- Yes, steel H-beams can be used for solar panel supports. Steel H-beams provide excellent structural stability and strength, making them a suitable choice for supporting the weight of solar panels. Additionally, steel beams are durable and resistant to environmental factors, making them a reliable option for long-term support of solar panels.

- Q: Can steel H-beams be used for residential garages?

- Certainly! Residential garages can indeed utilize steel H-beams. These beams are frequently employed in construction owing to their robustness and endurance. They offer exceptional structural reinforcement, rendering them well-suited for purposes such as garage construction. Steel H-beams present several benefits, including their ability to withstand bending and warping, which ensures the stability of the garage's framework. Moreover, these beams possess a remarkable load-bearing capacity, enabling them to bear heavy weights, such as vehicles and stored items. By opting for steel H-beams in the establishment of residential garages, one can achieve a resilient and long-lasting structure that provides ample safeguarding for both vehicles and belongings.

- Q: What is the maximum allowable camber for steel H-beams?

- The maximum allowable camber for steel H-beams is typically specified by the relevant industry standards or project specifications. The specific maximum allowable camber can vary depending on the size, grade, and intended use of the H-beam. It is important to consult these standards or specifications to determine the maximum allowable camber for a specific steel H-beam.

- Q: Are steel H-beams prone to bending or warping?

- Steel H-beams are known for their structural integrity and resistance to bending or warping. The design of H-beams, with their shape resembling the letter "H", provides excellent load-bearing capabilities, making them highly resistant to bending forces. The flanges of H-beams are wider and thicker than those of standard I-beams, allowing them to distribute weight evenly and resist bending or warping under heavy loads. Additionally, H-beams are typically made from high-strength steel, which further enhances their resistance to bending or warping. Therefore, it can be concluded that steel H-beams are not prone to bending or warping, making them a popular choice for various construction and structural applications.

- Q: How do you calculate the deflection limits for steel H-beams?

- To calculate the deflection limits for steel H-beams, several factors need to be taken into consideration. The deflection limits are typically determined by the applicable building codes or industry standards. The following steps outline the general process of calculating the deflection limits: 1. Determine the relevant building code or industry standard: The deflection limits are usually specified by building codes or industry standards, such as the American Institute of Steel Construction (AISC) code. These codes provide guidelines for the maximum permissible deflection based on the intended use of the structure. 2. Identify the properties of the H-beam: Gather the necessary information about the H-beam, including its dimensions, material properties, and support conditions. This information is typically provided by the manufacturer or can be obtained from relevant design resources. 3. Calculate the moment of inertia: The moment of inertia is a measure of the beam's resistance to bending. It is calculated based on the beam's dimensions and geometry. The moment of inertia plays a crucial role in determining the deflection of the beam. 4. Determine the applied load: Identify the load or loads that will act on the H-beam. This could include dead loads, live loads, wind loads, or any other relevant loads as specified by the design requirements. 5. Apply the appropriate deflection formula: The specific deflection formula to be used will depend on the type of loading and support conditions. Common deflection formulas include the Euler-Bernoulli beam equation, which assumes linear elastic behavior, and the Timoshenko beam equation, which accounts for shear deformations. 6. Calculate the maximum allowable deflection: Using the deflection formula, input the relevant parameters such as the applied load, beam properties, and support conditions to calculate the deflection at various points along the beam. Compare the calculated deflection values to the deflection limits specified in the building code or industry standard. 7. Ensure compliance with deflection limits: If the calculated deflection exceeds the specified limits, adjustments need to be made to the beam's dimensions, material, or support conditions. This may involve increasing the beam size, using a higher-strength material, or adding additional support. It is important to note that the process of calculating deflection limits for steel H-beams can be complex and may require the expertise of a structural engineer or designer. Additionally, it is crucial to adhere to the applicable building codes and industry standards to ensure the safety and structural integrity of the project.

- Q: Can steel H-beams be used in theater or stage construction?

- Certainly! Theater and stage construction can indeed utilize steel H-beams. These beams possess remarkable strength and durability, offering structural support for a wide range of construction purposes, including theater and stage design. H-beams commonly serve as the framework for stages, platforms, and rigging systems, ensuring stability and support for different components of a stage or theater set. Moreover, steel H-beams can be easily tailored and adjusted to fit the precise requirements and dimensions of theater or stage designs, thus exhibiting versatility for construction within the entertainment industry.

- Q: How do steel H-beams compare to concrete beams in terms of cost and performance?

- Steel H-beams and concrete beams have different characteristics in terms of cost and performance. In terms of cost, steel H-beams tend to have a higher upfront cost compared to concrete beams. This is primarily because steel is a more expensive material than concrete. However, steel H-beams often have a longer lifespan and require less maintenance than concrete beams. This can lead to cost savings over the long term due to reduced repair and replacement costs. In terms of performance, steel H-beams offer several advantages over concrete beams. Steel has a higher strength-to-weight ratio, which means that steel beams can support larger loads with less material. This allows for greater design flexibility and potentially reduces the number of beams needed in a structure. Steel is also more resistant to fire and seismic activities, making it a preferred choice for structures in high-risk areas. Concrete beams, on the other hand, have their own advantages. Concrete is a readily available material and is often less expensive than steel in some regions. Concrete beams also have good resistance to corrosion and can withstand harsh environmental conditions. Additionally, concrete has excellent thermal properties, which can contribute to energy efficiency in buildings. In conclusion, while steel H-beams may have a higher initial cost compared to concrete beams, they offer superior performance in terms of strength, durability, and resistance to fire and seismic activities. However, concrete beams have their own advantages in terms of availability, cost, and thermal properties. The choice between steel H-beams and concrete beams ultimately depends on the specific requirements of the project, budget constraints, and local regulations.

Send your message to us

Hot Rolled JIS Standard H Beams

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords