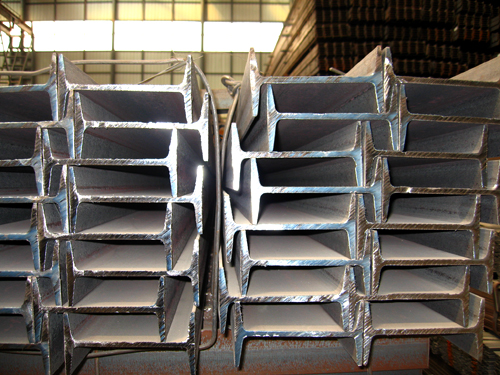

Hot Rolled Steel I-Beam with good quality for steel support

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering Hot Rolled Steel I-Beam with good quality for steel support at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beam with good quality for steel support applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS,

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Chinese Standard (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light I (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light II (H*W*T) | Weight (Kg/m) | 6M |

100*68*4.5 | 11.261 | 14.8 | 100*66*4.3 | 10.13 | 16.4 | 100*64*4 | 8.45 | 19.7 |

120*74*5.0 | 13.987 | 11.9 | 120*72*4.8 | 12.59 | 13.2 | 120*70*4.5 | 10.49 | 15.8 |

140*80*5.5 | 16.89 | 9.8 | 140*78*5.3 | 15.2 | 10.9 | 140*76*5 | 12.67 | 13.1 |

160*88*6 | 20.513 | 8.1 | 160*86*5.8 | 18.46 | 9 | 160*84*5.5 | 15.38 | 10.8 |

180*94*6.5 | 24.143 | 6.9 | 180*92*6.3 | 21.73 | 7.6 | 180*90*6 | 18.11 | 9.2 |

200*100*7 | 27.929 | 5.9 | 200*98*6.8 | 25.14 | 6.6 | 200*96*6.5 | 20.95 | 7.9 |

220*110*7.5 | 33.07 | 5 | 220*108*7.3 | 29.76 | 5.6 | 220*106*7 | 24.8 | 6.7 |

250*116*8 | 38.105 | 4.3 | 250*114*7.8 | 34.29 | 4.8 | 250*112*7.5 | 28.58 | 5.8 |

280*122*8.5 | 43.492 | 3.8 | 280*120*8.2 | 39.14 | 4.2 | 280*120*8 | 36.97 | 4.5 |

300*126*9 | 48.084 | 3.4 | 300*124*9.2 | 43.28 | 3.8 | 300*124*8.5 | 40.87 | 4 |

320*130*9.5 | 52.717 | 3.1 | 320*127*9.2 | 48.5 | 3.4 | |||

360*136*10 | 60.037 | 2.7 | 360*132*9.5 | 55.23 | 3 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Images:

- Q: Can steel H-beams be used in curved structures?

- Yes, steel H-beams can be used in curved structures. H-beams are versatile structural components that can be used in a variety of applications, including curved structures. They are commonly used in construction projects where curved or arched designs are desired, such as bridges, stadiums, and architectural structures. To create a curved structure using steel H-beams, the beams can be bent or curved to the desired shape. This can be done through various fabrication techniques, such as cold bending, hot bending, or rolling the beams. The ability to bend or curve steel H-beams allows for the creation of complex and aesthetically pleasing structures that can withstand the required loads and stresses. It is important to note that the process of bending or curving steel H-beams requires specialized knowledge, equipment, and expertise. Structural engineers, architects, and steel fabricators must work together to ensure that the curved structure meets the necessary design requirements and safety standards. Additionally, factors such as the type and grade of steel used, the bending radius, and the structural loads must be carefully considered during the design and fabrication process. In summary, steel H-beams can be used in curved structures by bending or curving them to the desired shape. With proper design and fabrication techniques, steel H-beams can provide structural support and stability in a wide range of curved architectural and construction projects.

- Q: Can steel H-beams be used in curved or sloped structures?

- No, steel H-beams are not typically used in curved or sloped structures as they are designed for straight and rigid construction. Curved or sloped structures usually require specialized curved beams or other structural elements that can accommodate the desired shape.

- Q: How do steel H-beams contribute to the overall aesthetics of a structure?

- The role of steel H-beams, also known as I-beams, in enhancing the aesthetics of a structure cannot be understated. These beams possess a unique design that can greatly enhance the visual appeal of any building or architectural project. One way in which steel H-beams contribute to aesthetics is through their sleek and modern appearance. The clean lines and sharp edges of these beams create a sense of precision and elegance, resulting in a visually pleasing and contemporary aesthetic. This effect is especially pronounced when the beams are left exposed or integrated into the building's design, showcasing their structural beauty. Moreover, steel H-beams offer versatility in architectural design, allowing for greater creativity and innovation. These beams can support large spans without the need for additional columns or walls, creating open and spacious interiors. The absence of obstructions promotes a sense of openness and fluidity, resulting in a visually appealing design. The use of steel H-beams also adds an industrial appeal to a structure. These beams, with their strong and durable nature, evoke a sense of robustness and stability. This industrial aesthetic can be particularly desirable in modern and contemporary designs, providing a contrast to materials like glass or wood and adding a unique visual element to the overall composition. Furthermore, the use of steel H-beams allows for efficient use of space, contributing to a more aesthetically pleasing structure. Architects can design buildings with fewer structural elements by utilizing these beams, resulting in cleaner lines and a more minimalist appearance. This streamlined approach creates a harmonious and balanced visual effect, enhancing the overall aesthetics of the structure. In conclusion, steel H-beams significantly contribute to the aesthetics of a structure through their clean and modern appearance, versatility in design, industrial appeal, and efficient use of space. Incorporating these beams into the architectural design can result in a visually pleasing and aesthetically appealing structure, elevating its impact and attractiveness.

- Q: Can steel H-beams be used in the construction of airports?

- Indeed, airports can utilize steel H-beams in their construction endeavors. Steel H-beams, renowned for their resilience and adaptability, are frequently employed within the construction sector for a multitude of structural applications. When it comes to airport construction, steel H-beams find themselves employed for an array of purposes. These include facilitating the roof structure of terminal buildings, establishing the framework for hangars, constructing bridges and walkways, as well as providing sturdy foundations for aircraft parking areas and runways. The utilization of steel H-beams in airport construction presents an enduring and cost-efficient resolution, guaranteeing the steadfastness and security of the airport's infrastructure.

- Q: How to declare the processed H steel? What is the rate of tax refund? Urgent urgent

- H steel customs matters if you want to share, HS, 72161010 section height is less than 80mmH steel (except for thermal processing without further processing) / HS, 72163311 section height of >800mmH steel (except for thermal processing without further processing) / HS, 200mm < 72163319 section height is less than or equal to 800mmH steel (except the heat the processing without further processing) your steel belongs to which HS will you choose!! The tax rebate rates for the 3 HS are 0.

- Q: 300 * 150 * 6.5 * 9 H steel is used as steel beam, span 6 meters, spacing 2 meters, laying steel plate, 15 cm soil

- The concrete strength grade of the slab does not know, the reinforcement does not know, the bearing capacity of the board can afford, it can not be calculated.

- Q: What are the different anti-corrosion treatments available for steel H-beams?

- There are several anti-corrosion treatments available for steel H-beams, including galvanizing, painting, epoxy coating, and powder coating. Galvanizing involves applying a layer of zinc coating to protect the steel from rust and corrosion. Painting involves applying a primer and topcoat to create a barrier between the steel and the environment. Epoxy coating is a type of paint that provides excellent corrosion resistance. Powder coating involves applying a dry powder to the steel and then baking it to create a durable and corrosion-resistant finish.

- Q: How do steel H-beams connect to other structural elements?

- Depending on the particular design and engineering needs of a project, Steel H-beams can be connected to other structural elements in various ways. One common approach involves the use of bolts or welds. When joining H-beams to other steel components like columns or beams, it is common to fasten them together using high-strength bolts. These bolts are inserted through pre-drilled holes in the flanges (the horizontal top and bottom sections) of the H-beam and then tightened with nuts. This establishes a secure and rigid connection between the H-beam and the other structural elements. Another method employed to connect steel H-beams to other structural elements is welding. In this case, the flanges of the H-beam are welded to the adjacent components, ensuring a robust and permanent connection. Welding is often favored when there is a need for high load-bearing capacity and structural integrity. Apart from bolts and welds, other connection methods such as connectors or brackets can also be utilized depending on the specific project requirements. These connectors or brackets are often designed to provide additional strength and stability to the connection between the H-beam and other structural elements. It is important to emphasize that the choice of connection method for steel H-beams is contingent upon various factors, including load-bearing capacity, structural design, and safety regulations. Structural engineers and designers meticulously consider these factors to ensure that the connection is strong, secure, and capable of withstanding the forces and loads imposed on the structure.

- Q: Can Steel H-Beams be used in religious or worship facility construction?

- Yes, Steel H-beams can definitely be used in religious or worship facility construction. In fact, steel H-beams are widely used in various types of construction projects due to their strength, durability, and versatility. They are particularly suitable for structures that require long-spanning beams or columns, which makes them an ideal choice for large religious or worship facilities such as churches, mosques, temples, or synagogues. Steel H-beams offer several advantages in religious facility construction. Firstly, they have excellent load-bearing capacity, allowing for the creation of open and expansive spaces without the need for numerous supporting columns or walls. This is especially beneficial in religious facilities, as it allows for unobstructed views and creates a sense of unity and connection among worshippers. Additionally, the use of steel H-beams enables architects and designers to incorporate unique and innovative designs, creating visually appealing and awe-inspiring worship spaces. Moreover, steel H-beams are resistant to fire, pests, and rot, making them a safe and long-lasting choice for religious structures. They are also highly durable and require minimal maintenance, ensuring the preservation of the facility's integrity and reducing potential repair costs over time. Furthermore, steel is a sustainable and environmentally friendly material. It is 100% recyclable, making it an eco-conscious choice for construction projects. By utilizing steel H-beams in religious facility construction, organizations can contribute to a greener future by reducing their carbon footprint. In conclusion, steel H-beams are an excellent choice for religious or worship facility construction. Their strength, durability, versatility, and sustainability make them a reliable option for creating spacious, visually appealing, and long-lasting worship spaces.

- Q: What are the common finishes available for steel H-beams?

- There are several common finishes available for steel H-beams, depending on the specific requirements and desired appearance. Some of the most commonly used finishes include: 1. Mill Finish: This is the most basic finish available for steel H-beams. It is the result of the manufacturing process and does not undergo any additional treatments or processes. As a result, it has a raw, untreated appearance with a slightly rough texture. 2. Hot-dip Galvanized: This finish involves immersing the steel H-beams in a bath of molten zinc, creating a protective coating. The process provides excellent corrosion resistance, making it suitable for outdoor applications where the beams may be exposed to harsh environmental conditions. 3. Primer Coating: Steel H-beams can also be coated with a primer, which acts as a protective layer against corrosion. This finish is commonly used when the beams will be further painted or coated with another layer of protective material. 4. Powder Coating: Powder coating is a popular finish option that involves applying a dry powder to the surface of the steel beams. The powder is then heated, causing it to melt and form a durable, protective layer. Powder coating offers a wide range of color options, as well as enhanced resistance to scratches, chipping, and fading. 5. Painted Finish: Steel H-beams can also be painted using traditional liquid paint. This finish provides a customizable appearance, as the beams can be painted in any desired color. However, it may require periodic maintenance and touch-ups to ensure long-term protection against corrosion. It is important to note that the specific finishes available may vary depending on the manufacturer or supplier. Therefore, it is advisable to consult with a professional or refer to the product specifications to determine the available finishes for steel H-beams.

Send your message to us

Hot Rolled Steel I-Beam with good quality for steel support

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords