Steel H Beam Profile with High Quality Structural Hot Rolled

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 250 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Specifications of Steel H Beam Profile with High Quality Structural Hot Rolled

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

Usage & Applications of Steel H Beam Profile with High Quality Structural Hot Rolled

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Steel H Beam Profile with High Quality Structural Hot Rolled

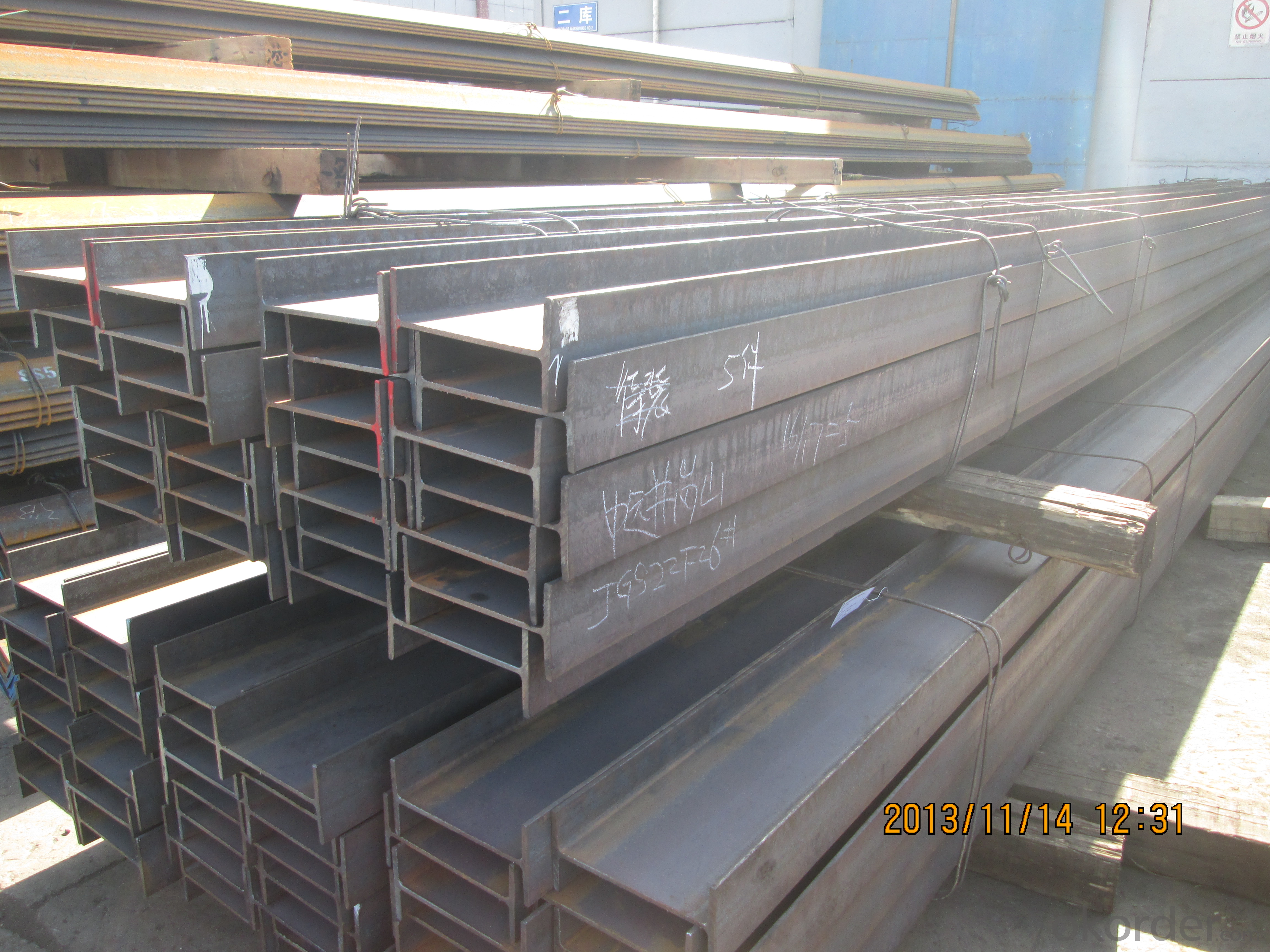

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Steel H Beam Profile with High Quality Structural Hot Rolled

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

Images

- Q: Can steel H-beams be used for educational buildings?

- Yes, steel H-beams can be used for educational buildings. Steel H-beams are commonly used in construction due to their strength, durability, and load-bearing capabilities. They provide structural support and can be used to create large open spaces, making them suitable for educational buildings such as schools, colleges, or universities. Additionally, steel H-beams are fire-resistant and have high seismic resistance, making them a safe and reliable choice for educational structures.

- Q: What are the considerations for selecting the appropriate fabrication method for steel H-beams?

- There are several factors to consider when choosing the right fabrication method for steel H-beams. These factors include the required dimensions, quality requirements, cost-effectiveness, and production volume. To begin with, the dimensions of the H-beam are crucial in determining the fabrication method. Different methods, such as hot rolling, cold bending, or welding, have their own limitations in terms of size and shape. It is important to ensure that the chosen fabrication method can meet the desired dimensions of the H-beam. Furthermore, the quality requirements of the H-beams should be carefully evaluated. This includes factors like strength, durability, and surface finish. Each fabrication method has its own impact on the final product's quality. For example, hot rolling is known for producing H-beams with superior strength and surface finish compared to cold bending. However, welding may introduce potential defects that can affect overall quality. Cost-effectiveness is another important consideration. Different fabrication methods have varying costs associated with them, including material, labor, and equipment expenses. The appropriate method should strike a balance between desired quality and fabrication costs. Lastly, the production volume also influences the choice of fabrication method. High-volume production often favors methods like hot rolling or welding, which offer higher efficiency and faster production rates. On the other hand, low-volume production allows for more flexibility in choosing methods that require more manual labor, such as cold bending. In conclusion, when selecting the right fabrication method for steel H-beams, it is important to consider dimensions, quality requirements, cost-effectiveness, and production volume. Finding a balance between these factors ensures the desired outcome in terms of both quality and cost.

- Q: How are steel H-beams different from other types of beams?

- Steel H-beams, also known as H-sections, are distinct from other types of beams due to their specific shape and structural properties. The main difference lies in their cross-sectional shape, which resembles the letter "H." This unique shape provides significant advantages over other beam types. Firstly, the H-beam's shape allows for a higher load-bearing capacity compared to other beams with similar weight. This is because the shape of the H-beam distributes the weight evenly along its length, maximizing its ability to withstand heavy loads. As a result, H-beams are widely used in construction projects that require strong and durable structural support, such as in the construction of high-rise buildings, bridges, and industrial facilities. Secondly, H-beams offer greater structural stability. The flanges, or top and bottom horizontal sections of the H-beam, provide resistance against bending and twisting forces. This characteristic makes H-beams more resistant to deformations and enables them to maintain their shape under heavy loads. Furthermore, the web, or vertical section of the H-beam, provides additional support and rigidity, ensuring the overall stability of the structure. Another key advantage of H-beams is their versatility. Due to their inherent strength and stability, H-beams can span longer distances without the need for intermediate supports. This allows for larger open spaces and more flexible architectural designs. Additionally, H-beams can be easily welded together to create longer beams, further expanding their application possibilities. Lastly, H-beams offer cost-effectiveness. Despite their robustness, H-beams are relatively lightweight compared to their load-bearing capacity. This reduces transportation costs and simplifies the installation process, making them a cost-effective choice for construction projects. In summary, steel H-beams differ from other types of beams due to their unique cross-sectional shape, which provides increased load-bearing capacity, structural stability, versatility, and cost-effectiveness. These characteristics make H-beams the preferred choice for various construction applications where strength, durability, and efficiency are crucial factors.

- Q: Can steel H-beams be used for solar panel supports?

- Yes, steel H-beams can be used for solar panel supports. H-beams, also known as I-beams or universal beams, are commonly used in construction due to their strength and durability. They provide excellent structural support and can withstand the weight and wind loads associated with solar panel installations. Steel H-beams also have the advantage of being resistant to corrosion, making them suitable for outdoor applications such as solar panel supports. Additionally, their versatility allows for easy installation and adjustment to accommodate different solar panel sizes and angles. Therefore, steel H-beams are a reliable and widely used choice for supporting solar panels.

- Q: How do steel H-beams contribute to the overall stability of a structure?

- Steel H-beams contribute to the overall stability of a structure in several ways. Firstly, their unique shape allows for a high strength-to-weight ratio, meaning they can support a significant amount of weight while remaining relatively lightweight. This is crucial for ensuring that the structure can withstand various loads and forces without collapsing. Additionally, steel H-beams have a wide flange and a narrow web, which enhances their bending and torsional resistance. This allows them to distribute the weight and forces evenly across their length, reducing the risk of localized stress concentrations and potential failure points. Moreover, the use of steel as a material for H-beams provides inherent durability and resilience. Steel is known for its high tensile strength, meaning it can resist tension forces and prevent the structure from deforming or collapsing under heavy loads or external pressures. This is especially important in earthquake-prone areas where the structure needs to withstand significant ground motion. Furthermore, steel H-beams can be easily connected together, forming a rigid and stable framework. These connections can be welded, bolted, or riveted, providing a strong and reliable bond between the beams. This ensures that the structure remains stable and can resist lateral forces such as wind or seismic loads. Overall, steel H-beams play a crucial role in ensuring the overall stability of a structure. Their strength, shape, and connection methods allow them to distribute loads efficiently, resist various forces, and provide a durable and stable framework for the entire structure.

- Q: How do steel H-beams perform in high humidity environments?

- Steel H-beams are known for their strength and durability, making them a popular choice for structural applications in various environments. In high humidity environments, however, steel H-beams may experience some effects due to the presence of moisture in the air. Steel is inherently resistant to corrosion, but prolonged exposure to high humidity can still cause some level of corrosion, especially if the steel is not properly protected. Humidity can lead to the formation of moisture on the surface of the steel, which can create a conducive environment for corrosion. To prevent corrosion in high humidity environments, various protective measures can be taken. The most common method is to apply a protective coating on the surface of the steel H-beams. The coating acts as a barrier, preventing moisture from reaching the steel and minimizing the risk of corrosion. Common coatings include paint, epoxy, or galvanization. Galvanization, in particular, provides excellent protection against corrosion in high humidity environments. It involves coating the steel with a layer of zinc, which acts as a sacrificial anode. When humidity causes the zinc coating to corrode, it sacrifices itself to protect the steel underneath, thus prolonging the lifespan of the H-beams. Additionally, proper ventilation and drainage play a crucial role in minimizing the effects of high humidity on steel H-beams. Adequate airflow can help reduce the moisture content in the environment, preventing excessive condensation on the steel surfaces. It's important to note that while steel H-beams can withstand high humidity environments, regular maintenance and inspection are necessary to ensure their long-term performance. Monitoring for any signs of corrosion and promptly addressing them can help maintain the structural integrity and longevity of the H-beams. In summary, steel H-beams can perform well in high humidity environments if they are properly protected and maintained. By applying appropriate coatings and ensuring good ventilation, the risk of corrosion can be significantly reduced, allowing the H-beams to maintain their strength and structural integrity over time.

- Q: What are the considerations when designing for accessibility in Steel H-Beams?

- When designing Steel H-Beams with accessibility in mind, there are several important factors to consider: 1. Clearances and dimensions: It is crucial to provide sufficient space around the H-Beams to accommodate wheelchair users and individuals with mobility aids. This involves allowing for maneuverability and ensuring that doorways, ramps, and other access points have appropriate dimensions for easy passage. 2. Ramps and slopes: It is essential to follow accessibility guidelines and standards when designing ramps or slopes for accessing H-Beams. This includes ensuring that the slope adheres to recommended limits, providing handrails for support, and considering the surface texture to prevent slips. 3. Handrails and guardrails: Installing handrails and guardrails along walkways or staircases near H-Beams is vital for safety and accessibility. These features should meet accessibility standards, including proper height and clearance, and provide a secure grip for users. 4. Surface materials and textures: Carefully selecting surface materials and textures for H-Beams can enhance accessibility. Slip-resistant surfaces are particularly important to prevent accidents, especially in wet or icy conditions. Tactile indicators or markings can also be incorporated to aid individuals with visual impairments in navigation. 5. Signage and wayfinding: Visible and clear signage is crucial for guiding individuals to H-Beams and helping them locate them easily. Using contrasting colors, large fonts, and braille signage can greatly improve accessibility for people with vision impairments. 6. Lighting and visual contrast: Adequate and well-distributed lighting is essential in areas with H-Beams to ensure safe navigation for individuals with visual impairments. Additionally, ensuring sufficient visual contrast between the H-Beams and their surroundings can assist individuals with low vision in identifying and distinguishing them. 7. Universal design principles: By incorporating universal design principles into the accessibility considerations for Steel H-Beams, designers can greatly enhance usability for a wide range of individuals. This involves accommodating people of all abilities, ages, and sizes, and taking factors like adjustability, reachability, and operability into account. By taking these factors into consideration, designers can create Steel H-Beams that prioritize accessibility, making them safe, usable, and inclusive for all individuals, regardless of their physical abilities.

- Q: What are the different types of steel H-beam profiles available?

- There are several different types of steel H-beam profiles available, each with its own unique characteristics and uses. Some of the most common types include: 1. Wide flange beams (W-beams): These beams have a wider flange and are commonly used in construction projects where strong support is required. They are known for their stability and resistance to bending. 2. American standard beams (S-beams): These beams have a narrower flange compared to wide flange beams and are often used in lighter structural applications. They are more cost-effective and easier to handle than wide flange beams. 3. Junior beams (J-beams): These beams have a lighter weight and smaller profile compared to wide flange and standard beams. They are commonly used in residential construction or smaller-scale projects. 4. European standard beams (HEB, HEM, and IPE beams): These beams follow European standards and are widely used in construction projects across Europe. HEB beams have a wide flange, while HEM beams have a wide flange and a higher moment of inertia. IPE beams have a narrower flange and are commonly used in residential buildings. 5. Japanese standard beams (JIS beams): These beams follow Japanese industrial standards and are commonly used in construction projects in Japan and other Asian countries. They are available in various sizes and profiles, including H, HP, and B series. 6. Universal beams (UB beams): These beams have a wide flange and are often used in construction projects where versatility and strength are required. They are commonly used in bridges, buildings, and other structural applications. 7. Tapered beams: These beams have a tapered flange, which allows for better weight distribution and load-bearing capacity. They are commonly used in roof trusses, bridges, and other applications where weight reduction is important. These are just a few examples of the different types of steel H-beam profiles available. The choice of profile depends on the specific requirements of the project, including load-bearing capacity, span, and cost-effectiveness. Consulting with a structural engineer or steel supplier can help determine the most suitable profile for a particular application.

- Q: What are the considerations for designing with steel H-beams?

- When it comes to designing with steel H-beams, there are several important factors that must be kept in mind. Firstly, it is crucial to have a clear understanding of the load-bearing capacity of the H-beams. This involves determining the maximum weight that the beams can support and making sure that the design takes into account any potential dynamic or live loads that may be applied. The required strength of the beams can be calculated through structural analysis and design calculations, considering factors such as the span length, beam size, and material properties. Another factor to consider is the overall structural stability and rigidity of the H-beam design. While H-beams are known for their high strength-to-weight ratio, they can be vulnerable to lateral torsional buckling under certain conditions. Analyzing and designing for these potential stability issues is important to ensure the safety and integrity of the structure. This may involve adding additional bracing or stiffeners to the H-beams to enhance their stability. Proper connection detailing is also a crucial aspect of designing with steel H-beams. The connections between the H-beams and other structural members, such as columns or beams, need to be carefully designed to ensure that loads are transferred correctly and that there is structural continuity. The type of connection, whether it is bolted, welded, or a combination of both, should be chosen based on factors such as expected loads, construction constraints, and desired structural flexibility. Fire resistance is another consideration when working with steel H-beams. While steel is inherently fire-resistant, it can lose its strength and stiffness when exposed to high temperatures for extended periods. Therefore, it is important to think about fire protection measures, such as fireproof coatings or the use of fire-resistant materials, to ensure that the H-beams maintain their structural integrity in the event of a fire. Lastly, the cost and availability of steel H-beams should be taken into account during the design process. The size, grade, and quantity of H-beams needed for the project can impact the overall cost and feasibility of the design. It is also important to consider the availability of the required H-beams in the market to avoid potential delays or cost overruns. In conclusion, designing with steel H-beams requires careful consideration of load-bearing capacity, structural stability, connection detailing, fire resistance, and cost factors. By addressing these factors, a well-designed H-beam structure can be achieved that meets the necessary performance criteria and ensures the safety and durability of the project.

- Q: Are steel H-beams recyclable?

- Yes, steel H-beams are recyclable. Steel is a highly recyclable material, and H-beams can be melted down and reused to manufacture new steel products, reducing waste and conserving resources.

Send your message to us

Steel H Beam Profile with High Quality Structural Hot Rolled

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 250 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords