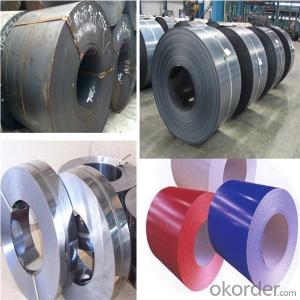

Hot Rolled/Cold Rolled Steel Strip Band Steel Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering Hot Rolled/Cold Rolled Steel Strip Band Steel Made In China at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled/Cold Rolled Steel Strip Band Steel Made In China are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled/Cold Rolled Steel Strip Band Steel Made In China are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Spring steel is divided into two types, one is alloy spring steel, and other one is carbon spring steel.

Alloy spring steel is a type that is used for manufacturing springs and other elastic parts. Spring steel should have high elastic limit and ratio of yield strength and tensile strength to make sure that the springs obtain enough power of elastic deformation and can bear much load.

Types of alloy spring steel: Si-Mn spring steel, Si-Cr spring steel, Cr-Mn Spring steel, Cr-V spring steel and so on.

Specification of Spring Steel Strip

-Material: 50CrVA

-Standard: GB/T 1222-2007

-Type: Spring Steel

Chemical Composition:

C | Si | Mn | S |

0.26~0.34 | 0.17~0.37 | ≤0.40 | ≤0.030 |

P | Cr | Ni | Cu |

≤0.030 | 2.00~2.50 | ≤0.35 | ≤0.25 |

V | W | ||

0.50~0.80 | 4.00~4.50 |

Mechanical Properties:

-Yield Strength σs (MPa): ≥1470 (150)

-Elongation δ10(%):≥7

-Hardness:

1, Hot rolled + Heat treatment, ≤321HB

2, Cold drawn + Heat treatment: ≤321HB

-Impact Power: ≥40

Norm of heat treatment:

1, Quenching: 1050℃~1100℃.

2, Cooled by oil.

3, Tempering: 600℃±50℃.

Usage/Applications of Spring Strip Steel:

-Due to the elements W, Cr and V, this type of spring steel obtain pretty high hardenability and nice mechanical properties under room temperature and high temperature. The tempering stability and hot workability are good.

-Being used under the state of quenching and high temperature tempering. It’s usually used as heat-resisting springs with working temperature below 500℃, like main secure valve spring of furnace and turbine steam seal leaf springs.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

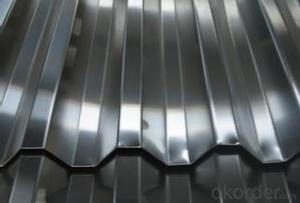

- Q: Can steel strips be used for roofing or siding purposes?

- Yes, steel strips can be used for roofing or siding purposes. Steel is a durable and long-lasting material that provides excellent protection against the elements, making it a popular choice for both roofing and siding applications.

- Q: What are the different surface coatings available for steel strips to improve lubricity?

- There are several surface coatings available for steel strips to enhance lubricity, including zinc phosphate, electroless nickel, PTFE (polytetrafluoroethylene), molybdenum disulfide, and diamond-like carbon (DLC) coatings. These coatings reduce friction and wear, providing better lubrication properties for the steel strips.

- Q: What are the dimensional inspection methods for steel strips?

- There are several dimensional inspection methods commonly used for steel strips. These methods are employed to ensure the accuracy and conformity of the dimensions of the steel strips to the specified standards. Some of the commonly used dimensional inspection methods for steel strips include: 1. Calipers: Calipers are used to measure the thickness, width, and length of the steel strips. They provide accurate measurements by directly comparing the dimensions of the steel strip with the calibrated scale on the caliper. 2. Micrometers: Micrometers are precision instruments used to measure the thickness and width of steel strips with high accuracy. They can measure dimensions up to the micrometer level, ensuring precise measurements. 3. Optical comparator: Optical comparators use magnification and illumination to compare the dimensions of the steel strip with a reference standard. This method enables visual inspection and measurement of various dimensions, such as width, length, and shape. 4. Laser measurement: Laser measurement systems utilize laser beams to measure the dimensions of steel strips accurately. They can provide non-contact measurements of width, thickness, and other dimensions, ensuring high precision and speed. 5. Coordinate measuring machine (CMM): CMM is a highly precise and automated dimensional inspection method. It uses a probe to measure multiple dimensions of the steel strip, including length, width, thickness, and even complex geometries. CMMs provide highly accurate measurements and are suitable for inspection of various steel strip profiles. 6. Vision systems: Vision systems use cameras and image processing algorithms to inspect the dimensions of steel strips. They can measure dimensions such as width, length, and thickness, and can also detect surface defects or irregularities. These dimensional inspection methods are often used in combination to obtain comprehensive and accurate measurements of steel strips. The selection of the appropriate method depends on the specific requirements, accuracy needed, and the type of steel strip being inspected.

- Q: Can steel strips be used in the production of bicycle frames?

- Yes, steel strips can be used in the production of bicycle frames. Steel is a popular material choice for bicycle frames due to its strength, durability, and affordability. It can be formed into strips and welded or brazed together to create a robust and reliable frame.

- Q: Can steel strips be used in HVAC systems?

- Yes, steel strips can be used in HVAC systems. Steel is a versatile and durable material that can be used for various components in HVAC systems, such as ductwork, ventilation, and air handling units. Steel strips are often used for reinforcement and structural support in these systems due to their strength and resistance to corrosion.

- Q: How are steel strips used in the railway industry?

- Steel strips have a wide range of uses in the railway industry. One key application is in the production of railway tracks. These strips are shaped into rails that form the track structure. They are typically hot-rolled, providing the necessary strength, durability, and stability. Steel strips are also utilized in the construction of railway bridges and tunnels. They are often used as reinforcement in concrete structures, enhancing their load-bearing capacity and structural integrity. Additionally, steel strips can be used as tie plates to evenly distribute the load and prevent the rail from sinking into the wooden ties. Besides track and infrastructure applications, steel strips are used in manufacturing various railway components. These include rail clips, fishplates, and fasteners. Rail clips secure the rails to the sleepers, ensuring proper alignment and preventing lateral movement. Fishplates connect two rail sections seamlessly, allowing for a smooth transition. Fasteners, such as bolts and nuts, maintain the stability and safety of the track. Furthermore, steel strips are essential in the fabrication of rolling stock components. They form the structural framework of railway wagons and locomotives, providing strength and rigidity. Steel strips are also utilized in the production of interior and exterior parts like doors, panels, and frames. In conclusion, steel strips are vital in the railway industry as they offer the necessary strength, durability, and stability to tracks, infrastructure, and rolling stock components. Their versatility and excellent mechanical properties make them an essential material for ensuring the safe and efficient operation of railways.

- Q: Are steel strips commonly used in the manufacturing of HVAC systems?

- Yes, steel strips are commonly used in the manufacturing of HVAC systems. They provide structural support and durability to the system components.

- Q: What are the main factors affecting the fatigue life of steel strips?

- The main factors affecting the fatigue life of steel strips are the material properties of the steel, the applied stress levels, the presence of surface defects or imperfections, the environmental conditions such as temperature and humidity, and the loading frequency or cycle count.

- Q: How do steel strips perform in terms of fatigue resistance?

- Steel strips have excellent fatigue resistance due to their high strength and durability. They can withstand repeated loading and cyclic stress without experiencing significant degradation or failure, making them highly suitable for applications that require long-term performance under dynamic conditions.

- Q: What are the specifications for steel strips used in the production of watches?

- The specifications for steel strips used in the production of watches can vary depending on the specific requirements of the watch manufacturer. However, there are some general specifications that are commonly used in the industry. Firstly, the steel strips used in watch production are typically made from high-quality stainless steel. Stainless steel is chosen for its durability, corrosion resistance, and aesthetic appeal. The thickness of the steel strip can vary, but it is usually in the range of 0.10 to 0.30 millimeters. This thickness allows for the creation of thin and lightweight watch components while still maintaining structural integrity. The width of the steel strip is also an important specification and can vary depending on the design and size of the watch. Common widths for watch steel strips range from 4 to 20 millimeters. In terms of surface finish, watch steel strips are often polished to achieve a smooth and shiny appearance. The level of polish can vary, with some watches featuring a high mirror-like finish, while others may have a brushed or matte finish. Another important specification is the hardness of the steel strip. Watch components require a certain level of hardness to ensure they can withstand daily wear and tear. The hardness is usually measured on the Rockwell scale, with a typical range of 45 to 60 HRC (Rockwell C scale). Furthermore, the steel strips used in watch production may undergo additional treatments such as heat treatment, coating, or plating to enhance their performance, durability, or visual appeal. It is important to note that these specifications can vary depending on the specific watch brand and model, as different manufacturers may have their own unique requirements and preferences. Therefore, it is essential for watchmakers to ensure they source steel strips that meet their specific specifications and quality standards.

Send your message to us

Hot Rolled/Cold Rolled Steel Strip Band Steel Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords