Hot Rolled Grade Sup6_Sup7_Sup9_SUP9A_Sup10 Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Rolled Grade Sup6_Sup7_Sup9_SUP9A_Sup10 Steel Flat Bar Steel Flat Bar

Details of Hot Rolled Grade Sup6_Sup7_Sup9_SUP9A_Sup10Steel Flat Bar

Name | Hot Rolled Grade Sup6_Sup7_Sup9_SUP9A_Sup10Steel Flat Bar |

Shape | Flat Bar |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

steel flat bar grade | Sup6_Sup7_Sup9_SUP9A_Sup10 |

steel flat bar standard | GB, ASTM, AISI, EN, JIS |

steel flat bar thickness | 1.8mm-17.75mm |

steel flat bar width | 10mm-870mm |

steel flat bar length | 6m, 9m, 12m or as customer requirement |

steel flat bar technique | Slitting hot rolled steel coil |

Chemical Composition of Hot Rolled Grade Sup6_Sup7_Sup9_SUP9A_Sup10 Steel Flat Bar

| Chemical Compositional Chart | ||||||||

| Standard | Material/ Grade | C | SI | Mn | Cr | V | P | s |

| ≤ | ||||||||

| DIN 17221 | 60SiCr7 | 0.57-0.65 | 1.50-1.80 | 0.70-1.00 | 0.20-0.40 | 0.03 | 0.03 | |

| 55Cr3 | 0.52-0.59 | ≤0.40 | 0.70-1.00 | 0.70-1.00 | 0.025 | 0.025 | ||

| 60Cr3 | 0.56-0.64 | 0.17-0.37 | 0.70-1.00 | 0.70-1.00 | 0.025 | 0.025 | ||

| 50CrV4 | 0.47-0.55 | 0.15-0.40 | 0.70-1.00 | 0.70-1.10 | 0.10-0.20 | 0.03 | 0.03 | |

| JIS G4801 | SUP6 | 0.55-0.65 | 1.50-1.80 | 0.70-1.00 | 0.035 | 0.035 | ||

| SUP7 | 0.55-0.65 | 1.80-2.20 | 0.70-1.00 | 0.035 | 0.035 | |||

| SUP9 | 0.52-0.60 | 0.15-0.35 | 0.65-0.95 | 0.65-0.95 | 0.03 | 0.03 | ||

| SUP9A | 0.56-0.64 | 0.15-0.35 | 0.70-1.00 | 0.70-1.00 | 0.03 | 0.03 | ||

| SUP10 | 0.47-0.55 | 0.15-0.35 | 0.65-0.95 | 0.80-1.10 | 0.15-0.25 | 0.03 | 0.03 | |

| SAE J1268 | 9260/H | 0.55-0.65 | 0.70-1.20 | 0.65-1.10 | ≤0.2 | 0.04 | 0.03 | |

| 5155 | 0.50-0.60 | 0.15-0.35 | 0.65-1.10 | 0.60-1.00 | 0.04 | 0.03 | ||

| 5160/H | 0.55-0.65 | 0.15-0.35 | 0.65-1.10 | 0.60-1.00 | 0.04 | 0.03 | ||

| 6150 | 0.47-0.54 | 0.15-0.35 | 0.60-1.00 | 0.75-1.20 | ≤0.15 | 0.04 | 0.03 | |

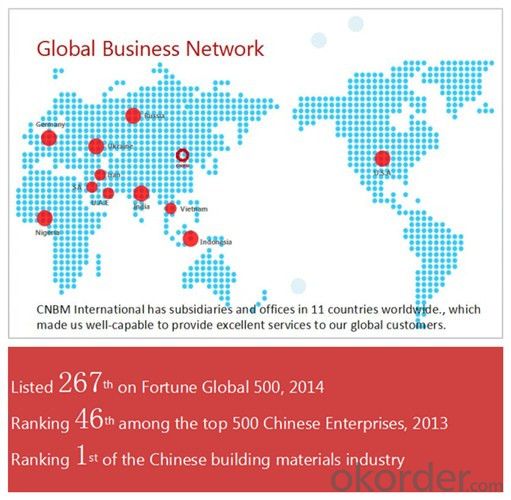

CNBM Introduction of Hot Rolled Grade Sup6_Sup7_Sup9_SUP9A_Sup10 Steel Flat Bar Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery Hot Rolled Grade Sup6_Sup7_Sup9_SUP9A_Sup10 Steel Flat Bar Supplier

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

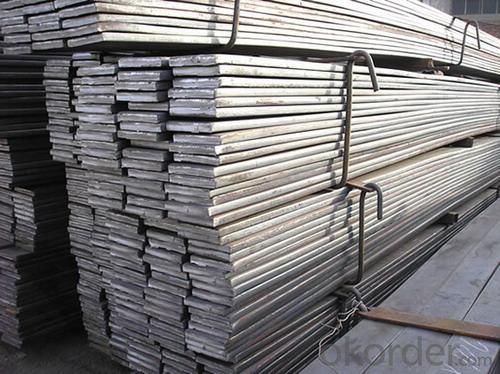

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the main manufacturing processes for special steel?

- The main manufacturing processes for special steel include electric arc furnace (EAF) melting, vacuum degassing, continuous casting, hot rolling, heat treatment, and finishing operations such as machining and surface treatment. These processes ensure the production of high-quality specialized steel with desired properties and performance characteristics.

- Q: What are the properties of corrosion-resistant steel?

- Corrosion-resistant steel, also known as stainless steel, possesses several key properties. Firstly, it has a high resistance to corrosion, making it suitable for use in environments with exposure to moisture or corrosive substances. Secondly, it contains a minimum of 10.5% chromium, which forms a protective layer called chromium oxide on the surface, preventing further corrosion. Additionally, it has a strong resistance to staining, which makes it easy to clean and maintain. Moreover, corrosion-resistant steel exhibits excellent strength and durability, making it suitable for a wide range of applications in various industries.

- Q: What are the effects of different heat treatment processes on special steel?

- Different heat treatment processes can have significant effects on the properties and performance of special steel. These processes are designed to alter the microstructure of the steel, thereby influencing its hardness, strength, toughness, and other mechanical properties. One commonly used heat treatment process is annealing, which involves heating the steel to a specific temperature and then slowly cooling it down. Annealing helps to relieve internal stresses, improve machinability, and enhance the ductility of the steel. It also refines the grain structure, making the steel more uniform and reducing the risk of cracks or other defects. Another heat treatment process is quenching, where the steel is heated to a high temperature and then rapidly cooled by immersing it in a quenching medium such as oil or water. This process results in the formation of a hardened microstructure, increasing the steel's hardness and wear resistance. However, quenching can also make the steel brittle, so it is often followed by a tempering process. Tempering involves reheating the quenched steel to a lower temperature and holding it there for a specific duration. This process helps to reduce the brittleness caused by quenching and improve the steel's toughness and ductility. The resulting microstructure is a balance between hardness and toughness, making the steel suitable for applications that require both strength and impact resistance. Other heat treatment processes, such as normalizing and stress relieving, can also be used to achieve specific properties in special steel. Normalizing involves heating the steel to a temperature above its critical point and then allowing it to cool in still air. This process refines the grain structure and improves the steel's strength and machinability. Stress relieving, on the other hand, aims to remove residual stresses from the steel by heating it to a temperature below its critical point and then slowly cooling it. In summary, the effects of different heat treatment processes on special steel are manifold. These processes can modify the steel's microstructure, resulting in changes in hardness, strength, toughness, and other mechanical properties. By selecting the appropriate heat treatment process, manufacturers can tailor the steel's characteristics to suit specific applications, ensuring optimal performance and longevity.

- Q: Can special steel be used in the production of jewelry?

- Indeed, it is possible to utilize special steel in the fabrication of jewelry. While precious metals such as gold, silver, and platinum are frequently employed in the art of jewelry making, there is an emerging inclination towards incorporating unconventional materials like special steel. The distinctive attributes of special steel, namely its durability, strength, and resistance to corrosion, allow for the creation of exquisite and intricate designs that cater to a contemporary and bold aesthetic. Moreover, special steel jewelry often presents a more economical alternative to traditional precious metal jewelry, rendering it a favored choice for individuals seeking a distinctive and budget-conscious option. Nevertheless, it is crucial to bear in mind that special steel jewelry necessitates proper care and maintenance to prevent tarnishing and scratching.

- Q: What are the properties of high-temperature alloy steel?

- High-temperature alloy steel possesses properties such as excellent heat resistance, high strength, good oxidation and corrosion resistance, and the ability to maintain mechanical properties at elevated temperatures. It is also known for its resistance to thermal fatigue, creep, and thermal shock, making it suitable for applications in high-temperature environments.

- Q: How does special steel contribute to the industrial equipment industry?

- The industrial equipment industry greatly relies on special steel for its superior strength, durability, and ability to withstand harsh conditions. Specially engineered steel alloys possess exceptional properties that suit a wide range of applications in industrial equipment. One of the main advantages of special steel is its ability to endure high temperatures and pressure, making it ideal for producing components like boilers, turbines, and heat exchangers. With its high heat resistance, special steel ensures efficient and reliable operation in demanding environments, enhancing performance and safety. Moreover, special steel is well-known for its excellent corrosion resistance, making it suitable for manufacturing equipment that encounters corrosive substances. This includes chemical processing equipment, oil and gas pipelines, and marine structures. By utilizing special steel in these applications, the industrial equipment industry can prolong operational lifetimes, reduce maintenance costs, and minimize the risk of catastrophic failures. Special steel also contributes to the industry by enabling the production of equipment with superior mechanical properties. Its unique composition and heat treatment processes increase strength, toughness, and wear resistance. Consequently, industrial equipment made from special steel can handle heavy loads, endure extreme conditions, and provide long-lasting performance. Furthermore, special steel alloys can be customized to meet specific requirements, allowing for the production of tailor-made components. This flexibility empowers the industrial equipment industry to design and manufacture equipment that precisely meets the diverse needs of sectors such as aerospace, automotive, energy, and construction. The versatility and adaptability of special steel play a crucial role in driving innovation and technological advancements within the industry. To summarize, special steel significantly contributes to the industrial equipment industry by providing exceptional strength, durability, resistance to harsh conditions, and customized solutions. Its unique properties make it an essential material for manufacturing a wide range of equipment, ultimately enhancing performance, reliability, and safety across various sectors.

- Q: Can special steel be used for jewelry?

- Yes, special steel can be used for jewelry. Special steel, such as stainless steel or titanium, is often used in jewelry making due to its durability, resistance to tarnish and corrosion, and its hypoallergenic properties. It can be crafted into various designs and finishes, offering a stylish and affordable alternative to traditional precious metals like gold or silver.

- Q: What are the different types of spring steel?

- There are several different types of spring steel, including high-carbon spring steel, alloy spring steel, stainless steel, and music wire.

- Q: What are the characteristics of special stainless steel?

- Special stainless steel is known for its unique properties that set it apart from regular stainless steel. Some of the key characteristics of special stainless steel include: 1. High Corrosion Resistance: Special stainless steel has a higher level of corrosion resistance compared to regular stainless steel. It can withstand exposure to harsh environments, such as saltwater or acidic substances, without corroding or deteriorating. 2. High Temperature Resistance: Special stainless steel is designed to withstand high temperatures without losing its structural integrity. It can endure extreme heat, making it suitable for applications in industries like aerospace, automotive, and power generation. 3. Enhanced Strength and Durability: Special stainless steel is often alloyed with other elements to enhance its strength and durability. This makes it highly resistant to deformation, cracking, and wear, ensuring its longevity and reliability in demanding conditions. 4. Excellent Mechanical Properties: Special stainless steel exhibits exceptional mechanical properties, including high tensile strength, toughness, and ductility. These properties make it ideal for applications that require high load-bearing capacity, such as structural components and machinery. 5. Unique Magnetic Properties: Depending on its composition, special stainless steel can exhibit various magnetic properties, ranging from non-magnetic to highly magnetic. This versatility allows it to be used in applications where magnetic properties are required, such as magnetic resonance imaging (MRI) machines or electrical transformers. 6. Hygienic and Easy to Clean: Special stainless steel is known for its hygienic properties, which make it suitable for applications in the food and healthcare industries. It is non-porous, resistant to bacteria growth, and easy to clean, making it an ideal choice for equipment and surfaces that require strict sanitary standards. 7. Aesthetic Appeal: Special stainless steel is often used in architectural and design applications due to its aesthetic appeal. It can be polished to a mirror-like finish, giving it a sleek and modern look. Additionally, it can be easily shaped and welded, allowing for creative design possibilities. In summary, special stainless steel possesses a combination of high corrosion resistance, temperature resistance, strength, durability, excellent mechanical properties, unique magnetic properties, hygienic features, and aesthetic appeal. These characteristics make it a preferred choice for a wide range of industrial, commercial, and domestic applications.

- Q: How does special steel contribute to the nuclear industry?

- Special steel plays a crucial role in the nuclear industry for several reasons. Firstly, special steel is highly resistant to corrosion and can withstand extreme temperatures and pressures, making it an ideal material for the construction of nuclear reactors and other components. This is essential for ensuring the safety and longevity of nuclear power plants. Secondly, special steel is used in the fabrication of fuel assemblies and storage containers for nuclear fuel. These containers must be able to contain radioactive material safely and securely, and special steel provides the necessary strength and durability to prevent leakage or contamination. Furthermore, special steel is utilized in the construction of steam generators, which are essential components of nuclear power plants. Steam generators transfer heat from the reactor to the turbines, generating electricity. The high temperature and pressure conditions within steam generators demand a material that can withstand these harsh conditions, and special steel fulfills this requirement. Additionally, special steel is employed in the manufacturing of control rods, which are used to regulate the nuclear reaction within the reactor core. The control rods are inserted or withdrawn to control the rate of fission and maintain a stable reaction. Special steel's mechanical properties and resistance to radiation damage ensure the reliability and effectiveness of control rods. Moreover, special steel is used in the construction of shielding materials and containment structures that protect workers, the environment, and the general public from radiation exposure. These structures are designed to prevent the release of radioactive materials and are made with special steel due to its excellent radiation shielding properties. In summary, special steel contributes significantly to the nuclear industry by providing the necessary strength, durability, and resistance to corrosion, heat, and radiation. It enables the safe and efficient operation of nuclear reactors, the storage and transportation of nuclear fuel, and the protection of personnel and the environment.

Send your message to us

Hot Rolled Grade Sup6_Sup7_Sup9_SUP9A_Sup10 Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords