Hot Rolled SUP10 Spring Steel Bar,Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Hot Rolled SUP10 Spring Steel Bar,Round Bar

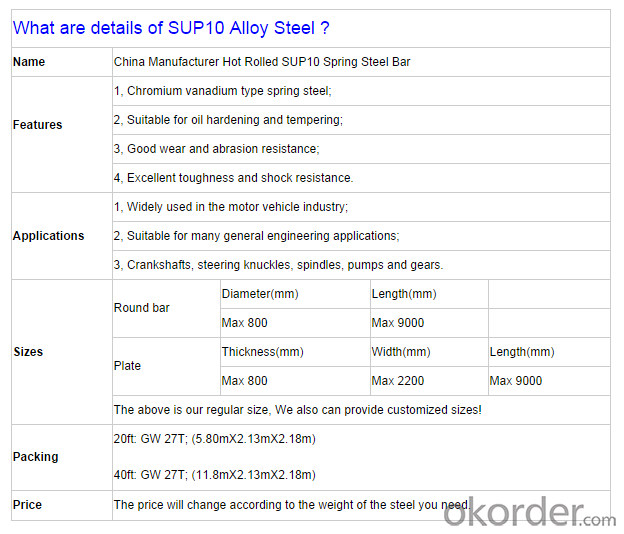

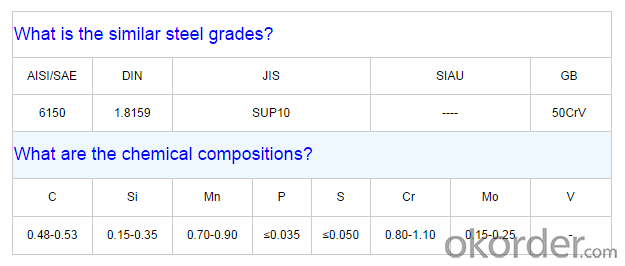

Product information:

Product show

Workshop show

Our service:

- Q: Can steel round bars be coated for improved aesthetics?

- Indeed, steel round bars have the potential to be coated for enhanced aesthetics. By applying a coating to steel round bars, their appearance can be elevated, resulting in a sleeker and more visually pleasing surface. Multiple coating alternatives, such as powder coating, electroplating, or painting, can be utilized to achieve diverse aesthetic outcomes when coating steel round bars. Moreover, these coatings offer more than just an improved appearance; they also grant additional advantages like increased resistance to corrosion and heightened durability. As a result, the practice of coating steel round bars is widely employed across various domains, including architecture, decoration, and industry, to enhance their aesthetics.

- Q: What is the standard length of a steel round bar?

- The standard length of a steel round bar varies depending on the manufacturer and the specific application. However, common standard lengths range from 6 to 12 feet (1.8 to 3.6 meters).

- Q: Can steel round bars be used for making conveyor belts or rollers?

- Certainly, conveyor belts or rollers can be made using steel round bars. Steel possesses remarkable tensile strength and durability, rendering it appropriate for tasks involving heavy loads or incessant motion. The round bars can be utilized to establish the conveyor belt or roller's structural framework or support system, ensuring stability and rigidity. Furthermore, steel exhibits resistance to wear and tear, as well as the capability to endure high temperatures, thereby making it perfect for industrial environments. Nevertheless, it is crucial to take into account other aspects such as the conveyor system's specific requirements, the type of material being transported, and any potential corrosion concerns that might arise.

- Q: How are steel round bars used in the manufacturing of hydraulic systems?

- Steel round bars are commonly used in the manufacturing of hydraulic systems due to their strength, durability, and versatility. These bars serve various purposes in the construction and assembly of hydraulic components. One primary use of steel round bars in hydraulic systems is for the fabrication of piston rods. Piston rods are crucial components of hydraulic cylinders, responsible for transferring the force generated by the hydraulic fluid to the desired mechanism. The high strength and rigidity of steel round bars make them ideal for this application, as they can withstand the intense pressure and stress exerted on the piston rod during operation. Steel round bars are also utilized in the manufacturing of shafts and axles within hydraulic systems. These components are responsible for transmitting rotational motion and torque from the hydraulic pump to other mechanical parts, such as gears or pulleys. By using steel round bars, manufacturers can ensure the reliability and longevity of these critical parts, as they possess excellent mechanical properties and resistance to wear and tear. Additionally, steel round bars are often employed in the construction of hydraulic fittings and connectors. These components are responsible for joining different hydraulic pipes, hoses, or valves together, creating a sealed system for fluid transmission. Steel round bars provide the necessary strength and stability to withstand the high-pressure conditions within hydraulic systems, ensuring leak-free operation and the efficient transfer of fluids. In summary, steel round bars play a vital role in the manufacturing of hydraulic systems by providing strength, durability, and versatility. Their use in piston rods, shafts, axles, fittings, and connectors ensures the proper functioning and reliability of these systems.

- Q: How are steel round bars tested for quality and strength?

- Steel round bars are tested for quality and strength through a series of standardized procedures. These include visual inspection, dimensional checks, and mechanical testing. Visual inspection ensures that the surface is free from any defects or imperfections. Dimensional checks measure the diameter, length, and straightness of the bars, ensuring they meet the specified requirements. Mechanical testing involves subjecting the bars to various tests like tensile, hardness, and impact tests to determine their strength, toughness, and ability to withstand different loads and conditions. These tests ensure that the steel round bars meet the necessary quality and strength standards.

- Q: Can steel round bars be used for making musical instruments?

- Yes, steel round bars can be used for making musical instruments. They can be used to create various percussion instruments such as steel drums or xylophones. The steel round bars can be tuned to produce specific musical notes and can be shaped and crafted to achieve the desired sound.

- Q: What are the advantages of using silicon-alloy steel round bars?

- There are several advantages to using silicon-alloy steel round bars. Firstly, silicon-alloy steel has excellent strength and durability. It is known for its high tensile strength, which makes it suitable for applications that require heavy-duty performance. This strength also allows it to withstand heavy loads and resist deformation, making it a reliable choice for various mechanical and structural purposes. Secondly, silicon-alloy steel round bars have good heat resistance. The presence of silicon in the alloy improves its ability to handle high temperatures without losing its structural integrity. This makes it ideal for applications that involve exposure to extreme heat, such as in furnace components, exhaust systems, or high-temperature equipment. Additionally, silicon-alloy steel round bars offer excellent corrosion resistance. The alloying elements in silicon-alloy steel, such as chromium and nickel, help create a protective oxide layer on the surface, preventing the metal from corroding and prolonging its lifespan. This makes it suitable for use in marine environments or corrosive atmospheres. Furthermore, silicon-alloy steel round bars have good machinability and weldability. This means that they can be easily formed into various shapes and sizes, making them versatile for different manufacturing processes. The ability to weld silicon-alloy steel allows for easy fabrication and customization, making it a convenient choice for many industries. Lastly, silicon-alloy steel round bars are cost-effective. Compared to other high-performance alloys, silicon-alloy steel is relatively more affordable, making it a cost-effective option for applications that require strength, durability, and resistance to heat and corrosion. In conclusion, the advantages of using silicon-alloy steel round bars include excellent strength and durability, good heat resistance, corrosion resistance, machinability, weldability, and cost-effectiveness. These qualities make silicon-alloy steel a versatile and reliable material for various industrial applications.

- Q: Are steel round bars suitable for use in the mining industry?

- Yes, steel round bars are suitable for use in the mining industry. Steel round bars are known for their strength, durability, and resistance to wear and tear, making them ideal for various mining applications. They can be used in the construction of machinery, equipment, and infrastructure within mines, as well as for support structures such as mine shafts and tunnels. The high tensile strength of steel round bars allows them to withstand heavy loads and extreme conditions commonly encountered in mining operations.

- Q: What is the maximum aluminum content allowed for steel round bars?

- The maximum aluminum content allowed for steel round bars varies depending on the specific steel grade and industry standards. In general, the aluminum content in steel round bars is typically limited to a maximum of 0.03-0.06% for most commercial and structural steel grades. However, there are certain specialized steel grades, such as those used in the aerospace industry, where higher levels of aluminum content may be allowed. It is important to consult the specific steel grade's technical specifications or industry standards to determine the maximum allowable aluminum content for steel round bars.

- Q: Can steel round bars be used for making cooling system components?

- Certainly, cooling system components can be fabricated using steel round bars. Steel, being a versatile and resilient material, possesses the capability to endure elevated temperatures and pressures, rendering it ideal for cooling system applications. Steel round bars can be precisely shaped and dimensioned to meet the varying requirements of distinct cooling system components such as pipes, fittings, valves, and heat exchangers. Furthermore, steel exhibits exceptional thermal conductivity, enabling efficient heat transfer within cooling systems. However, it is vital to meticulously consider the specific demands of the cooling system and seek advice from engineers or professionals to ascertain the appropriate grade of steel and ensure compatibility with other system components.

Send your message to us

Hot Rolled SUP10 Spring Steel Bar,Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords