Hot Rolled Checkered Steel Plate Diamond Plate Tread Plate for Truck Beds Trailer Floors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

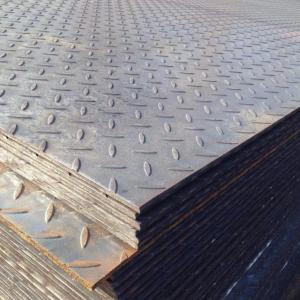

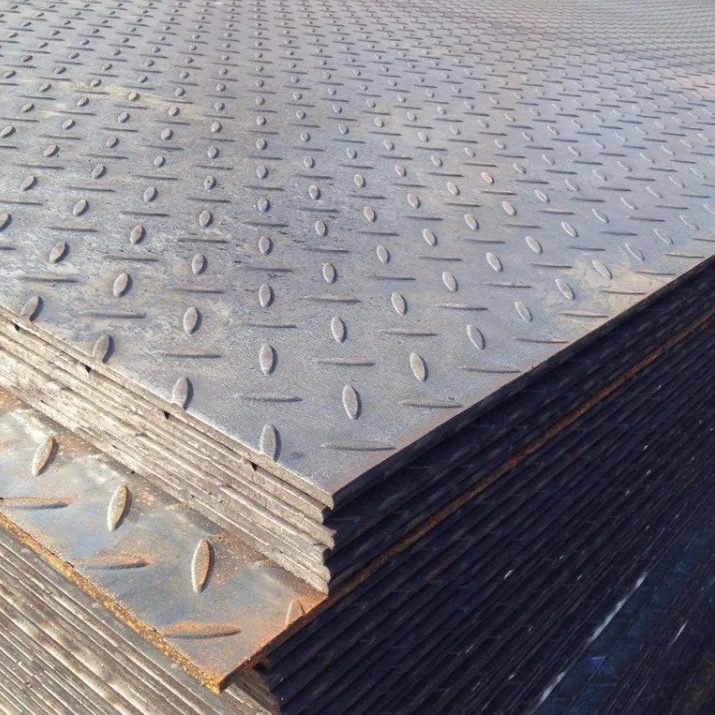

Hot Rolled Checkered Steel Plate

Diamond plate, also known as checker plate and tread plate, Is a type of metal stock with a regular pattern of raised diamonds or lines on one side, with the reverse side being featureless.

Diamond plate is usually steel, stainless steel or aluminum. Steel types are normally made by hot rolling, although modern manufacturers also make a raised and pressed diamond design.

The added texture reduces the risk of slipping, making diamond plate a solution for stairs, catwalks, walkways, and ramps in

industrial settings.

Its non-skid properties mean that diamond plate is frequently used on the interior of ambulances and on the footplates of firetrucks. Additional applications include truck beds and trailer floors.

Specifications of Hot Rolled Checkered Steel Plate

Technique: | hot rolled |

Thickness | 1.2mm to 12mm |

Width: | MAX 1500MM |

Normal width: | 914mm, 1000mm, 1200mm, 1219mm,1250mm,1500mm |

Length: | According to requirement |

Coil ID: | 762mm |

Coil Weight: | 10-25 Metric Tons |

Surface: | oiled/unoiled |

Port of Loading: | Tianjin/Shanghai port |

Packaging Details: | Standard export packing or according to the clients required |

Delivery Time | Within 30 days after received 30% deposit or workable L/C |

Pictures of Hot Rolled Checkered Steel Plate

- Q: 7850kg/cu.m density is typical for all type of steel? like reibar, I- beam and so on

- 90% of the steels used today are plain mild carbon steels consisting of iron with less than 1% carbon content and as such have a density of about 7750 kg/cubic meter. Some special steels which have a significant percentage of alloying elements such as chrome or manganese or other elements will have greater density bringing the steel up to about 8000 kg / cubic meter. There are a greater many factors influencing the exact density of a steel. Even for steels of exactly the same content of iron , carbon and other alloying elements, there may be a difference ( very small mind you ) in density due to work hardening. The difference in this case is due to movement of dislocations which become locked in the grain boundaries and this forms a more dense crystal structure. For this same reason, the theoretical density of steel (which does not take into account dislocations) is greater than the measured density of steel.

- Q: How are steel coils inspected for bendability?

- Steel coils are inspected for bendability through a combination of visual examination, mechanical testing, and dimensional analysis. Visual inspection involves identifying any visible defects such as cracks, dents, or surface irregularities that could affect the coil's bendability. Mechanical testing is conducted to measure the coil's resistance to bending and evaluate its flexibility. This includes performing bend tests to determine the coil's ability to withstand a specified degree of bending without breaking or cracking. Additionally, dimensional analysis is performed to ensure that the coil meets the required thickness, width, and length specifications, as these factors also impact its bendability.

- Q: How are steel coils inspected for defects after rewinding?

- Steel coils are inspected for defects after rewinding by using various techniques such as visual inspection, ultrasonic testing, magnetic particle inspection, and eddy current testing. These methods help identify surface irregularities, cracks, or other defects that may have occurred during the rewinding process, ensuring the quality and integrity of the steel coils.

- Q: I have a necklace that has a pendent made out of stainless steel. The pendent is connected by a cord, not chain, that I can take on and off; so, I leave it on all the time. It has gotten pretty tarnished because of that.

- steel jewelry Daily care? Just need a soft cloth just fine. Or you can use toothpaste to clean the stailess steel jewelry.

- Q: What are the common coil slitting methods?

- The common coil slitting methods include rotary shear, loop slitting, and double knife slitting.

- Q: What materials are used to make steel coils?

- Steel coils are primarily made from a material called steel, which is an alloy composed mainly of iron and carbon. The specific type of steel used to make coils depends on the desired properties and applications. Generally, carbon steel is the most common type used, as it offers strength, durability, and versatility. Other alloying elements may be added to enhance certain properties or characteristics of the steel, such as manganese, silicon, nickel, or chromium. The production of steel coils involves melting down the raw materials, refining the molten steel, and then shaping it into coils using specialized equipment and processes.

- Q: hello, I am trying to figure out what wok to get and came across a website that offers many woks out of different materials. what is the best, or considered original (traditional)? I have a couple of cast iron pots and pans - too heavy, so I am assuming it will take some time for a cast iron wok to heat up. what about carbon steel and stainless steel? Thanks

- Carbon steel is definitely the way to go. This is the authentic wok. Of course, you must be aware that it can rust if not dried--but in use you will seldom wash it anyway. The correct practice is simply to wipe it out with a paper towel. In this way the wok keeps its natural non-stick qualities. Whenever it is washed it must be re-seasoned--by heating it very hot with salt. Stainless steel of course does not rust and makes a pretty picture hanging up--but its utility ends there. It does not have the heat conduction qualities that are needed. Still, there are other factors which go into wok cooking (such as degree of heat available) which have nothing to do with the wok. With that in view, a SS wok might be your choice, but from a cooking standpoint, carbon is better. One added factor you must consider is thickness of the steel. Cheap woks will flex readily if grasped by the handles. A quality wok is twice as thick. It is not too much to aim for 1/8 thickness, or nearly that. There is also the flat bottomed Shanghai wok which is about 1/4 thick and usually comes with a teflon finish. These are very inexpensive but useful because they can be heated up to a high temperature which it will hold to a certain extent. The bane of wok cookery is insufficient heat. (I have an electric stove right now which exhibits that defect).

- Q: How are steel coils used in the production of electrical transmission poles?

- Steel coils are used in the production of electrical transmission poles as the primary material for constructing the pole itself. The steel coils are typically cut and shaped into the desired dimensions, then welded together to form the pole structure. This provides strength, durability, and stability to withstand the load and environmental conditions associated with electrical transmission lines.

- Q: How do steel coils compare to other materials?

- There are multiple advantages to using steel coils instead of other materials. Firstly, steel is renowned for its strength and durability, which makes steel coils highly resistant to wear and tear. This quality allows them to be used in a wide range of applications. Additionally, steel coils have excellent heat resistance, making them ideal for high-temperature environments. Furthermore, steel coils offer superior corrosion resistance compared to many other materials. This is especially important in industries like construction and automotive, where exposure to moisture and chemicals is common. Steel coils can withstand these harsh conditions, ensuring long-lasting performance and reliability. Another benefit of steel coils is their versatility. Steel can be easily molded into various shapes and sizes, allowing for customization and flexibility in design. As a result, steel coils are suitable for a wide range of applications in manufacturing, construction, transportation, and energy industries. Moreover, steel coils provide good value for money. Despite their numerous benefits, steel coils are generally more affordable than materials like aluminum or copper. This makes steel coils a cost-effective choice for businesses and industries seeking high-quality and reliable materials. In summary, steel coils offer multiple advantages over other materials. They possess high strength, durability, and heat resistance, along with superior corrosion resistance. Steel coils are also versatile and easily customizable for different applications. Additionally, they provide good value for money. Overall, steel coils are a dependable and efficient option for various industries and applications.

- Q: How are steel coils inspected for surface defects using non-destructive testing methods?

- To ensure the quality and integrity of steel coils, non-destructive testing (NDT) methods are employed to inspect them for surface defects. Several common NDT methods are utilized in this process. Visual inspection is one of the most widely used methods, where trained inspectors visually examine the steel coils for visible defects like scratches, cracks, pits, or corrosion. Although this method is simple and cost-effective, it can only detect surface-level defects. Magnetic particle testing (MT) is another commonly used NDT method. It utilizes magnetism to identify surface and near-surface defects in ferromagnetic materials like steel. By applying a magnetic field and iron particles to the steel coil, any defects such as cracks or discontinuities become visible as the iron particles concentrate around them. Liquid penetrant testing (PT) is a different NDT method used for inspecting steel coils. It involves applying a liquid penetrant to the coil's surface, which is drawn into surface defects through capillary action. After removing excess penetrant and applying a developer, the defects become visible as the developer draws out the penetrant. Ultrasonic testing (UT) is widely used to detect both surface and subsurface defects in steel coils. It transmits high-frequency sound waves into the coil and analyzes the reflected waves to identify abnormalities. This method can detect defects like cracks, inclusions, and voids that may not be visible to the naked eye. Additionally, eddy current testing (ECT) is another NDT method for inspecting steel coils. It utilizes electromagnetic induction to detect surface and near-surface defects. By placing a coil carrying an alternating current near the surface of the coil being inspected, any changes in the coil's electrical conductivity caused by surface defects are detected and analyzed to identify and evaluate their severity. In summary, various non-destructive testing methods such as visual inspection, magnetic particle testing, liquid penetrant testing, ultrasonic testing, and eddy current testing are utilized to inspect steel coils for surface defects. These methods ensure the quality and integrity of the steel coils before they are used in various applications.

Send your message to us

Hot Rolled Checkered Steel Plate Diamond Plate Tread Plate for Truck Beds Trailer Floors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords