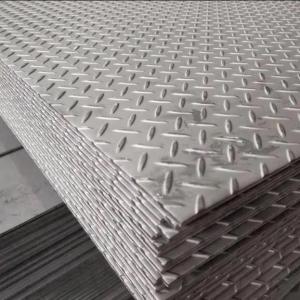

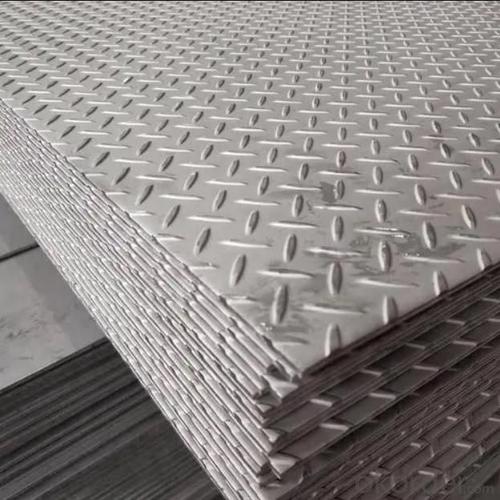

Hot Rolled Steel Chequered Skid Resistance Sheets Chequer Plates

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Steel Chequered

The steel surface with a pattern called chequered, its pattern into lentil-shaped, diamond, round bean-shaped, oblate shape mixed.

Features

Checkered appearance, can slip, strengthen performance, saving steel and many other advantages.

In transportation, construction, decoration, floor surrounding equipment, machinery, shipbuilding and other fields have a wide range of applications.

Generally, parties to checkered mechanical properties, mechanical performance requirements, so checkered pattern quality mainly as flowering rate, the pattern height, elevation pattern.

Currently on the market common thickness ranging from two kinds of width are common 1250,1500mm from 2.0-8mm.

Specifications

1. Plate width 600 ~ 1800mm, 50mm press upgrade; length of 2000 ~ 12000mm, press the 100mm upgrade.

2. High grain pattern is not less than 0.2 times the thickness of the substrate. Size does not figure as a finished check basis.

3. Plate steel grades according to GB / T700, GB / T712, GB / T4171 requirements.

4. Mechanical properties of steel does not guarantee, when required by the demand side, according to standard regulations, but also by mutual agreement.

5. Hot-rolled steel sheet delivery.

Pictures

- Q: What is the difference between a coated and uncoated stainless steel sheet?

- A coated stainless steel sheet is one that has undergone a protective layer or finish application, which can be a polymer or another material. This coating enhances the sheet's ability to resist corrosion, scratches, and other types of damage. Moreover, the coating offers decorative appeal by presenting various colors or textures. In contrast, an uncoated stainless steel sheet refers to a sheet without any additional protective layer or finish. It retains its natural state, with its inherent properties and characteristics. Uncoated stainless steel sheets are renowned for their exceptional resistance to corrosion, durability, and strength. They are commonly employed in situations where their natural properties are sufficient to withstand the intended environment. The primary distinction between coated and uncoated stainless steel sheets lies in their protective capabilities and appearance. Coated sheets provide an extra layer of protection against corrosion and damage, making them suitable for environments exposed to harsh conditions or corrosive substances. Additionally, they offer a wider range of design options due to the various coatings available. On the other hand, uncoated stainless steel sheets are preferred in applications where the inherent properties of stainless steel are adequate to meet the requirements. They are often utilized in architectural and structural projects, as well as in industries such as food processing, pharmaceuticals, and medical equipment, where hygiene and durability are crucial. To summarize, the difference between coated and uncoated stainless steel sheets lies in the additional protective layer and aesthetic options offered by the coating. Coated sheets provide enhanced resistance to corrosion and damage, along with a broader range of design choices. Uncoated sheets rely on their inherent properties for durability and strength. The selection between the two hinges on the specific application and the desired balance between protection, aesthetics, and cost.

- Q: What are the different types of steel sheet alloys?

- There are several different types of steel sheet alloys, each with its own unique properties and applications. Some of the most common steel sheet alloys include: 1. Carbon Steel: This is the most basic type of steel and contains mainly iron and carbon. It is widely used in construction, automotive, and manufacturing industries due to its strength and affordability. 2. Stainless Steel: Known for its corrosion resistance, stainless steel is made by adding chromium and other alloying elements to carbon steel. It is commonly used in applications where hygiene and durability are important, such as kitchen appliances, medical equipment, and architectural structures. 3. Galvanized Steel: This type of steel is coated with a layer of zinc to protect it from corrosion. Galvanized steel sheets are often used in outdoor applications, such as roofing, fencing, and automotive parts. 4. Alloy Steel: Alloy steel sheets are made by adding various alloying elements, such as nickel, chromium, and molybdenum, to carbon steel. These alloys enhance the strength, hardness, and wear resistance of the steel, making it suitable for applications in industries like aerospace, automotive, and machinery. 5. Tool Steel: Tool steel is specifically designed for the production of tools and dies. It is characterized by its high hardness, resistance to deformation, and ability to retain sharp edges. Tool steel sheets are commonly used in the manufacturing of cutting tools, drills, and molds. 6. Electrical Steel: This type of steel has been specially processed to have low magnetic losses and high electrical conductivity. Electrical steel sheets are used in the production of transformers, electric motors, and generators. These are just a few examples of the different types of steel sheet alloys available. Depending on the specific requirements of a project or application, engineers can choose the appropriate alloy to achieve the desired properties and performance.

- Q: How do steel sheets perform in terms of corrosion resistance?

- Steel sheets generally have good corrosion resistance, especially when they are coated with protective layers such as zinc or alloys. The corrosion resistance of steel sheets depends on the composition and quality of the steel, as well as the environment in which they are utilized. Stainless steel sheets, for example, offer high resistance to corrosion due to the presence of chromium and other alloying elements. These sheets are particularly effective in environments with high humidity, saltwater exposure, or acidic conditions. However, uncoated or low-alloy steel sheets may be prone to rust and corrosion in aggressive environments. Regular maintenance, such as applying protective coatings or using corrosion inhibitors, can enhance the corrosion resistance of steel sheets and prolong their lifespan.

- Q: What is the reflectivity of steel sheets?

- The reflectivity of steel sheets can vary depending on factors such as the type of steel, its surface finish, and the angle of incidence of light. In general, steel sheets have a moderate to high reflectivity, especially when polished or coated. However, they are not as reflective as materials like silver or aluminum.

- Q: Is galvanized steel plate or iron plate?

- Therefore, iron does not exist in practical applications. Another pure iron is very soft, or mechanical performance is not good, that is, if it does not oxidize, it can not be used. And we usually use the most is the iron carbon alloy, and the iron carbon alloy called "steel" in the metal, so from the academic angle to the iron carbon content is less than 0.008% that of iron, steel when the majority of coke, so the production process to burn the whole carbon is almost impossible to the. Therefore, the said carbon content is less than 0.008%, and iron can not be obtained by common iron making methods.

- Q: Are steel sheets suitable for agricultural machinery?

- Yes, steel sheets are suitable for agricultural machinery due to their durability, strength, and ability to withstand harsh conditions commonly encountered in farming operations.

- Q: Are steel sheets suitable for magnetic shielding applications?

- Indeed, magnetic shielding applications find steel sheets to be fitting. Being a magnetic material, steel possesses the capability to redirect magnetic fields effectively, thereby diminishing their intensity or averting their access to specific regions. Employing steel sheets as a barricade ensures the protection of delicate electronic equipment and devices against external magnetic interference. The thickness and composition of the steel sheet can be modified accordingly to attain the desired degree of magnetic shielding. Furthermore, steel sheets are frequently deemed economical and easily accessible, rendering them a pragmatic selection for magnetic shielding applications.

- Q: Are the steel sheets resistant to atmospheric corrosion?

- Yes, steel sheets are generally resistant to atmospheric corrosion. However, the level of resistance can vary depending on the specific type of steel used and the environmental conditions it is exposed to. For instance, stainless steel sheets are highly resistant to atmospheric corrosion due to the presence of chromium, which forms a protective oxide layer on the surface. On the other hand, carbon steel sheets may be more susceptible to corrosion if they are not properly coated or treated. Additionally, the presence of pollutants, humidity, and other factors in the atmosphere can also affect the corrosion resistance of steel sheets. Therefore, it is important to consider these factors and choose the appropriate type of steel and protective measures to ensure long-term resistance to atmospheric corrosion.

- Q: What is the cost of steel sheets compared to other materials?

- The cost of steel sheets compared to other materials can vary depending on factors such as the type of material, size, thickness, and market conditions. In general, steel sheets tend to be more expensive than materials like aluminum or plastic, but they are also known for their durability and strength. Steel sheets are commonly used in industries such as construction, automotive, and manufacturing due to their high load-bearing capacity and resistance to corrosion. While steel sheets may have a higher upfront cost, they often provide a longer lifespan and require less maintenance compared to other materials. Additionally, the cost of steel sheets can fluctuate based on global supply and demand dynamics, as well as any tariffs or trade restrictions that may impact the steel market.

- Q: What is a die steel plate?

- Pressure plate template is made of galvanized steel sheet or the antiseptic treatment, the machine rolled into a groove plate with a cross section of the ladder waveform or project template material open box steel shell.

Send your message to us

Hot Rolled Steel Chequered Skid Resistance Sheets Chequer Plates

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords