Hot Rolled Carbon Steel Plate Sheet Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Rolled Carbon Steel Plate_Sheet Prices

Thickness:0.6-200mm

Width:1000-4000mm

MOQ: 1 ton

Certificate:ISO,SGS

Hot Rolled Carbon Steel Plate_Sheet Prices

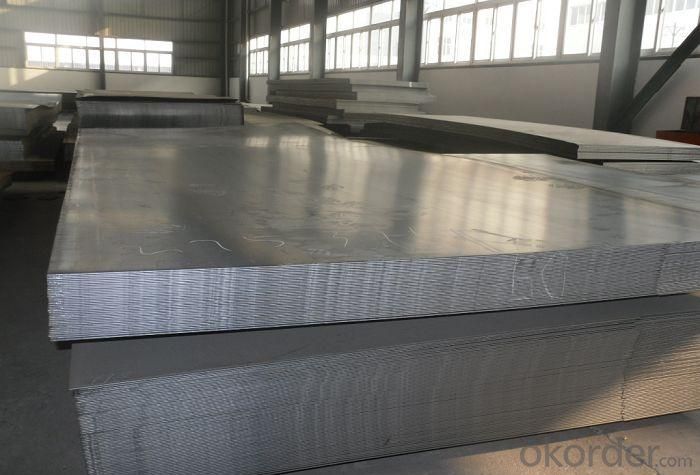

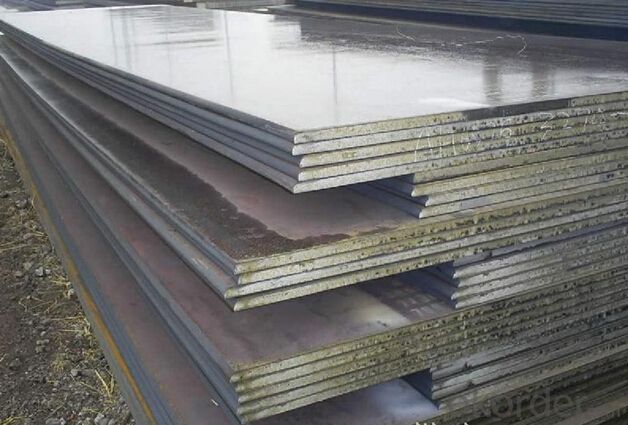

Commodity | Prime hot rolled carbon steel plate / sheet dimensions |

Thickness | 0.6-200mm |

Width | 1000-4000mm |

Length | as custom's request |

Technique | Cold rolled or hot rolled mild steel plate |

Surface treatment | Bare, galvanized coated or as customer's requirements. |

Standard | ASTM,EN,GB,JIS |

Material | A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235 SAE1010,SAE1020,SAE1045,Q195,Q235,Q345,SS400,ASTM A36,E235B mild steel plate |

Usage | the mild steel plate will used in home appliances construction, machinery manufacturing, container manufacturing, shipbuilding, bridges, etc. |

Terms of Payment | 30% T/T as deposit and 70% T/T balance againest B/L copy. |

Delivery Detail | Within 3-15 days after receipt of deposited for the mild steel plate |

CNBM Introduction of Hot Rolled Carbon Steel Plate_Sheet Prices

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery of Hot Rolled Carbon Steel Plate_Sheet Prices

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the different powder coating techniques used for special steel?

- There are several powder coating techniques used for special steel, including electrostatic spray, fluidized bed, and flame spraying. Each technique offers unique advantages and is chosen based on factors such as the desired coating thickness, complexity of the surface, and specific properties required for the steel's functionality.

- Q: How does the availability of raw materials affect the production of special steel?

- The availability of raw materials plays a crucial role in the production of special steel. Special steel is a high-quality alloy that is used in various industries such as automotive, aerospace, and energy. It is known for its exceptional strength, durability, and resistance to corrosion, making it a preferred choice for critical applications. The availability of raw materials, such as iron ore, coal, and alloying elements like chromium, nickel, and molybdenum, directly affects the production of special steel. These raw materials are essential for the composition and properties of the steel, and any disruptions in their supply can significantly impact the production process. If the availability of iron ore, which is the primary source of iron, is limited or becomes costly, it can lead to a scarcity of the main ingredient for steel production. This can cause a decrease in the production of special steel, resulting in higher prices and potential shortages in the market. Similarly, the availability and cost of alloying elements are critical factors. Alloying elements enhance the properties of steel, making it suitable for specific applications. For example, chromium increases the steel's resistance to corrosion, while molybdenum improves its strength at high temperatures. If these alloying elements are not readily available, it may affect the ability to produce special steel with the desired properties. Furthermore, the availability of energy resources, such as coal or natural gas, is also important for the production of special steel. These resources are used in the steelmaking process, specifically in the production of coke, which is essential for the smelting of iron ore. Limited availability or increased prices of energy resources can impact the cost and efficiency of steel production. In conclusion, the availability of raw materials is a critical factor in the production of special steel. Any disruptions or limitations in the supply of raw materials, including iron ore, alloying elements, and energy resources, can have a significant impact on the production process, leading to higher prices, potential shortages, and compromised properties of the final product. Therefore, ensuring a stable and sufficient supply of raw materials is essential for the production of high-quality special steel.

- Q: How does special steel perform in high-temperature environments?

- Special steel is specifically designed to perform well in high-temperature environments. It has excellent heat resistance, retaining its strength and hardness even at elevated temperatures. Special steel also exhibits good oxidation and corrosion resistance, reducing the risk of degradation or failure in high-temperature conditions. Overall, special steel is a reliable and durable material choice for applications requiring performance in high-temperature environments.

- Q: Can special steel be used for making marine components?

- Yes, special steel can be used for making marine components. Special steel, also known as marine grade steel, is specifically designed to withstand the harsh conditions of marine environments. These environments are exposed to corrosion, high humidity, and saltwater, which can cause regular steel to deteriorate quickly. Marine grade steel is typically made with added alloys, such as nickel, chromium, and molybdenum, which provide excellent corrosion resistance and durability. These alloys help the steel resist the corrosive effects of saltwater and prevent rusting. Additionally, special steel is often coated with protective coatings or treated to further enhance its resistance to corrosion. Marine components made from special steel include ship hulls, propellers, shafts, valves, pipelines, and various structural elements. The use of special steel ensures the longevity and reliability of these components in demanding marine conditions. Furthermore, the strength and toughness of special steel make it suitable for withstanding the high mechanical stresses and impacts experienced at sea. In summary, special steel is an ideal material for making marine components due to its superior corrosion resistance, durability, and strength. It helps to ensure the longevity and reliability of marine structures and equipment in harsh marine environments.

- Q: How does special steel contribute to the industrial machinery aftermarket industry?

- Special steel plays a crucial role in the industrial machinery aftermarket industry by providing high-quality, durable, and customized components that are essential for repairing and maintaining machinery. Its unique properties, such as high strength, toughness, corrosion resistance, and heat resistance, enable the production of precision components that can withstand heavy industrial usage. This contributes to the efficiency, reliability, and longevity of machinery, reducing downtime and overall costs for businesses in the aftermarket industry.

- Q: How does special steel contribute to the aerospace structural industry?

- Special steel plays a crucial role in the aerospace structural industry by offering exceptional strength, durability, and heat resistance. It is used extensively in the manufacturing of aircraft components such as landing gears, engine parts, and structural frames. The high tensile strength and corrosion resistance of special steel ensure the integrity and safety of the aircraft, enabling it to withstand extreme conditions and stress encountered during flight. Additionally, special steel's lightweight nature allows for increased fuel efficiency, reducing operational costs and environmental impact in the aerospace industry.

- Q: What are the challenges in machining high-speed special steel?

- Several challenges arise when machining high-speed special steel due to its unique properties and characteristics. Its extreme hardness presents one of the main obstacles, making cutting and shaping difficult. High-speed special steel typically has a high carbon content and undergoes heat treatment to enhance its hardness, resulting in increased wear on cutting tools. The increased hardness of this steel also leads to elevated heat generation during the machining process. This heat can cause thermal distortion and impact the dimensional accuracy of the final product. To counteract this, specialized cooling techniques and cutting tools with advanced coatings must be used to dissipate heat and maintain stability. Another challenge is the brittleness of high-speed special steel. It tends to have low toughness and is susceptible to cracking and chipping during machining operations. To minimize the risk of tool failure and excessive stress, careful selection of cutting parameters such as cutting speed, feed rate, and depth of cut is necessary. Furthermore, high-speed special steel often contains alloying elements like tungsten, vanadium, and cobalt, which can further complicate the machining process. While these elements increase the strength and wear resistance of the steel, they also make it more challenging to machine. Effective machining of these alloys and achieving desired surface finishes requires specialized tool materials and cutting strategies. Additionally, the cost of high-speed special steel is often significantly higher than that of conventional steels, adding to the challenges of machining. The high tooling costs associated with the cutting tools required for machining this steel can be a substantial investment. Overall, machining high-speed special steel necessitates advanced cutting techniques, specialized tooling, and careful consideration of cutting parameters to overcome the challenges posed by its extreme hardness, brittleness, and alloying elements.

- Q: How is corrosion-resistant steel used in marine environments?

- Corrosion-resistant steel is used extensively in marine environments due to its ability to withstand the harsh conditions of saltwater exposure. It is commonly used in the construction of ships, oil rigs, offshore platforms, and other marine structures. The steel's high resistance to corrosion helps prevent rusting and deterioration, ensuring the longevity and durability of these structures in the corrosive marine environment.

- Q: How does special steel contribute to reducing product defects during manufacturing?

- Special steel contributes to reducing product defects during manufacturing by offering superior strength, durability, and corrosion resistance properties. This high-quality material ensures that the manufactured products have a lower risk of breakage, wear, or deformation, reducing the likelihood of defects. Additionally, special steel's precise composition and uniformity enable accurate machining and forming processes, resulting in more accurate and consistent product dimensions. Its resistance to heat and pressure also minimizes the occurrence of thermal expansion or distortion, further reducing defects during manufacturing.

- Q: How does special steel perform in renewable energy applications?

- Special steel is a key component in various renewable energy applications and plays a significant role in their performance and durability. The unique properties of special steel, such as its high strength, corrosion resistance, and temperature stability, make it an ideal choice for use in renewable energy technologies. One of the major renewable energy applications where special steel excels is in wind turbines. Wind turbine components, such as the tower, rotor blades, and gearbox, require materials that can withstand harsh environmental conditions and high mechanical loads. Special steel alloys offer excellent strength-to-weight ratios, allowing for lighter and more efficient turbine designs. Additionally, their corrosion resistance properties ensure longevity and reduced maintenance requirements, resulting in increased reliability and overall performance of the wind turbine. In solar power applications, special steel is used in the construction of solar panels and support structures. Solar panels require frames made of durable material to withstand external forces and extreme weather conditions. By utilizing special steel, solar panels can be manufactured to be lightweight, yet strong enough to support the weight of the photovoltaic cells. Furthermore, the corrosion resistance of special steel ensures that the panels remain intact, even in harsh environments. Moreover, special steel is also employed in the production of hydroelectric power. In hydro turbines, the corrosive nature of water and the high pressure and temperature conditions necessitate the use of materials that can withstand such environments. Special steel offers excellent resistance to corrosion, erosion, and cavitation, making it a reliable choice for hydroelectric power generation. Its strength and durability ensure the turbines can operate efficiently and withstand the forces exerted by the flowing water. Overall, special steel performs exceptionally well in renewable energy applications by enhancing the reliability, longevity, and efficiency of various technologies. Its unique properties make it an indispensable material in wind turbines, solar panels, and hydroelectric power generation, contributing to the overall advancement and sustainability of renewable energy systems.

Send your message to us

Hot Rolled Carbon Steel Plate Sheet Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords