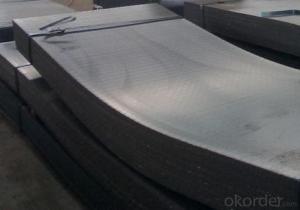

Hot Rolled Carbon Steel Plate,Carbon Steel Sheet E235B, CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI, ASTM, GB, JIS | Grade: | Q195,Q235,Q345,A36,C45 | Thickness: | 1.0-30MM |

| Model Number: | Q235,Q195,Q345 | ||||

| Type: | Steel Plate | Technique: | Hot Rolled | Surface Treatment: | Coated |

| Application: | Ship Plate | Special Use: | Silicon Steel | Width: | 30-2000mm |

| Length: | as your requirement | standard: | hot rolled | Surface: | Anti-rust oil |

Packaging & Delivery

| Packaging Details: | seaworthy packages or as customers' require |

| Delivery Detail: | within 15 days after the advance payment |

Hot rolled steel plate

1 carbon steel plate 3mm thick General information

| Product name | Type | Specification | Implementation of GB | ||

| thick | wide | long | |||

| Carbon structural steel | Q195,Q215, Q235A,Q235B, Q235C,Q255, Q275 | 4-120 | 1500-4500 | 6000-12000 | GB/T700-2006 |

| Low-alloy structural steel | Q295,Q345A, Q345B,Q2345C | 4-120 | 1500-4500 | 6000-12000 | BG/T1591-1994 |

| Quality carbon structural stee | 30-50 | 4-120 | 1500-4500 | 6000-12000 | BG/T699-1999 |

| Ship steel | CCSA,CCSB | 4-120 | 1500-4500 | 6000-12000 | materials and welding condition |

| CCSAH32,CCSAH36 CCSDH32,CCSDH36 | 4-120 | 1500-4500 | 6000-12000 | materials and welding condition or GB 712-2000 | |

| Boiler steel | 20g,22Mng, 16Mng,19Mng | 4-120 | 1500-4500 | 6000-12000 | GB 713-1997 |

| Pressure vessel steel | 1622Mng,20R, 15MnVR,15MnVNR | 4-120 | 1500-2700 | 6000-12000 | GB 6654-1996 |

| European standard plate

| S235JR,S235J0, S275JR,S275J0, S275JR2,S355JR, S355J0,S355J2 | 4-120 | 1500-4500 | 6000-12000 | EN 10025 |

| Japanese standard plate | SS400,SS400-B | 4-120 | 1500-4500 | 6000-12000 | JIS G3101-2004 |

2 carbon steel plate 3mm thick detail specification

Material:

A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D

SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235

Q195,Q235,Q345,SS400,ASTM A36,E235B

Thickness: 4mm-120mm

width: 1500mm-4500mm

Length:2-10m ,accordingly

Thickness | 4-120mm |

Width | 1500-4500mm or as custom's request |

Length | 2-12m,as your requirment |

Technique | Cold rolled or hot rolled |

Surface treatment | Bare, galvanized coated or as customer's requirements. |

Standard | ASTM,EN,GB,JIS,GB |

Material | A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235 Q195,Q235,Q345,SS400,ASTM A36,E235B |

Terms of Payment | L/C or T/T |

Chemical composition | C≤0.004%;Si≤0.030%; Mn ≤0.17%;P≤0.012%; S≤0.010%; Fe balance |

Delivery Detail | within 30days once receive deposite or confirm L/C |

Packing | Standard export packing,or as requirement |

3 carbon steel plate 3mm thick application:

construction,machinery manufacturing, container manufacturing, shipbuilding, bridge construction. Can also be used to manufacture a variety of containers, the furnace shell, furnace plate, bridge and vehicle static steel plate, low alloy steel plate,shipbuilding plate, boiler plate, pressure vessel plate, pattern plate, tractor parts, automobile frame steel plate and welding components

- Q: How are steel sheets protected during cutting and fabrication?

- To ensure the quality and prevent damage, various methods are employed to protect steel sheets during cutting and fabrication. One widely used approach is galvanizing, which entails applying a zinc coating to the surface of the steel sheet. This zinc coating acts as a barrier against corrosion and other forms of harm, making it particularly effective in outdoor settings where steel sheets are exposed to moisture and harsh elements. Another technique for safeguarding steel sheets during cutting and fabrication involves the use of lubricants or coolants. These substances are applied to both the cutting tools and the steel sheet itself to reduce friction and minimize heat generation. By doing so, lubricants and coolants help prevent warping and distortion of the steel sheet during the cutting and fabrication process. Moreover, protective films or tapes are often utilized during the fabrication of steel sheets. These films or tapes shield the sheets from scratches, abrasions, and other physical damage that may occur during handling or transportation. In addition to these methods, proper handling and storage practices play a crucial role in protecting steel sheets during cutting and fabrication. It is essential to store the sheets in a controlled environment to prevent exposure to damaging elements such as moisture and extreme temperatures. Additionally, they should be handled with care to avoid impacts or bending that could compromise their structural integrity. In summary, steel sheets are protected during cutting and fabrication through the combined use of surface coatings, lubricants or coolants, protective films or tapes, and proper handling and storage practices. These measures ensure the quality and durability of the sheets, allowing them to maintain their integrity throughout the fabrication process and beyond.

- Q: What are the common lengths of steel sheets?

- Common lengths of steel sheets can vary depending on the specific application and industry requirements. However, some commonly available lengths include 8 feet (2.44 meters), 10 feet (3.05 meters), and 12 feet (3.66 meters).

- Q: What is the typical hardness range for steel sheets?

- The typical hardness range for steel sheets can vary depending on the specific type of steel and its intended application. However, a common hardness range for steel sheets is between 20 and 60 on the Rockwell C scale.

- Q: What are the different types of steel sheet finishes for industrial applications?

- Various types of steel sheet finishes are commonly utilized in industrial applications for different purposes. These finishes are applied to steel sheets to improve their appearance, safeguard against corrosion, enhance paint adhesion, and offer other functional advantages. Among the most frequently employed steel sheet finishes are: 1. Hot Rolled: Achieved by subjecting the steel to high temperatures in a furnace, followed by rapid cooling. This process creates a rough, scaled surface suitable for applications where appearance is not the primary concern. 2. Cold Rolled: Processed at room temperature, resulting in a smooth and clean surface. Cold-rolled steel sheets are often used when a high-quality surface finish is required. 3. Galvanized: Involves applying a layer of zinc to the steel sheet to protect against corrosion. Widely used in construction, automotive, and manufacturing industries where durability and resistance to rust are crucial. 4. Electro-galvanized: Similar to galvanizing, this process coats the steel with zinc. However, it utilizes an electric current to deposit a thinner and more controlled zinc coating onto the steel surface. 5. Stainless Steel: Known for its high corrosion resistance, stainless steel sheets are ideal for use in harsh environments. They can be finished with various surface textures, including brushed, mirror, and patterned finishes. 6. Pickled and Oiled: This finish removes any oxide scale from the steel surface using an acid solution and applies an oil coating to prevent rust formation. Commonly used in automotive and construction industries. 7. Painted: Steel sheets can be finished with a layer of paint, which enhances their appearance and provides additional protection against corrosion. The choice of paint depends on the application and desired finish. It is important to note that the examples mentioned above are just a few of the steel sheet finishes used in industrial applications. Different finishes are selected based on specific requirements, such as aesthetics, corrosion resistance, durability, and cost-effectiveness.

- Q: Can steel sheets be used for bulletproof applications?

- Yes, steel sheets can be used for bulletproof applications. Steel is a strong and durable material that can effectively stop bullets from penetrating through it. Bulletproof steel sheets are often used in the manufacturing of armored vehicles, military equipment, and personal protective gear such as bulletproof vests and helmets. The thickness and quality of the steel sheets play a crucial role in determining their bulletproof capabilities. Steel sheets can be designed to withstand different levels of ballistic protection, ranging from handguns to high-powered rifles. Additionally, steel's affordability and ease of production make it a popular choice for bulletproof applications in various industries.

- Q: Can steel sheets be used for construction equipment?

- Construction equipment can indeed utilize steel sheets. Steel, a versatile and long-lasting material, finds widespread use in the construction industry for a range of purposes, including equipment fabrication. Steel sheets can be manipulated, joined, and shaped into various components and structures required for construction equipment like bulldozers, cranes, excavators, and dump trucks. The remarkable strength-to-weight ratio of steel renders it suitable for heavy-duty equipment, providing the necessary robustness and steadiness while managing weight effectively. Furthermore, steel boasts corrosion resistance, a crucial quality for construction equipment that confronts harsh environmental conditions. In summary, owing to their strength, durability, and versatility, steel sheets enjoy considerable popularity as a preferred option for construction equipment.

- Q: Can the steel sheets be used for magnetic shielding?

- Yes, steel sheets can be used for magnetic shielding. Steel is a ferromagnetic material, which means it can effectively redirect and absorb magnetic fields. When steel sheets are used to shield against magnetic fields, they create a barrier that helps to prevent the penetration of magnetic flux into a designated area. This property makes steel sheets an excellent choice for applications where magnetic shielding is required, such as in electronics, medical devices, and sensitive laboratory equipment. However, the effectiveness of steel sheets for magnetic shielding can depend on various factors, including the thickness and composition of the steel, as well as the strength and frequency of the magnetic field being shielded. Therefore, it is important to consider these factors and consult with experts to ensure the appropriate steel sheets are selected for optimal magnetic shielding.

- Q: Are the steel sheets perforated or solid?

- The steel sheets are perforated.

- Q: What are the different sheet metal welding techniques for steel sheets?

- Steel sheets can be joined using various sheet metal welding techniques. The most commonly used methods are as follows: 1. MIG welding, also known as Gas Metal Arc Welding (GMAW), involves the use of a continuous wire electrode to create an arc and join the steel sheets. This technique is versatile and efficient, suitable for both thin and thick sheets. 2. TIG welding, or Gas Tungsten Arc Welding (GTAW), utilizes a non-consumable tungsten electrode to create an arc and join the steel sheets. It produces high-quality welds with excellent control, making it ideal for thin or delicate sheet metal. 3. Resistance Spot Welding (RSW) involves applying pressure and passing a high electrical current through the steel sheets using two electrodes. This causes the sheets to fuse together swiftly and cost-effectively. It is commonly used in the automotive and manufacturing industries. 4. Laser Welding employs a high-energy laser beam to melt and join the steel sheets. The technique offers precise control, high welding speeds, and minimal heat input, making it suitable for thin and highly reflective materials. 5. Electron Beam Welding (EBW) utilizes a focused beam of high-velocity electrons to create a weld. It offers deep penetration and is often used for thick steel sheets or applications requiring high-quality welds. 6. Plasma Arc Welding (PAW) is similar to TIG welding but utilizes a plasma arc to create a weld. This technique provides higher welding speeds and can be used for both thick and thin steel sheets. The choice of welding technique depends on various factors such as the thickness of the steel sheets, desired weld quality, production volume, and available equipment. Each method has its own advantages and limitations.

- Q: What is the typical thermal conductivity of a steel sheet?

- The typical thermal conductivity of a steel sheet ranges from 14 to 50 watts per meter-kelvin (W/mK).

Send your message to us

Hot Rolled Carbon Steel Plate,Carbon Steel Sheet E235B, CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords