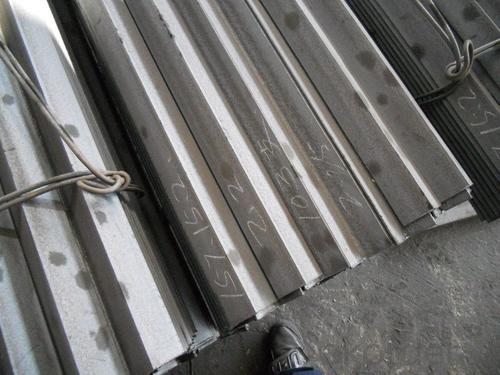

Hot Rolled Carbon Steel Equal Angle with Many Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Carbon Steel Equal Angle at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Product Advantages:

OKorder's Equal Angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: Can steel angles be used in HVAC ductwork installations?

- Yes, steel angles can be used in HVAC ductwork installations. They are commonly used to provide structural support and reinforcement to the ductwork system, ensuring stability and durability. Steel angles can be easily integrated into the ductwork design, facilitating efficient installation and improving overall system performance.

- Q: What is the maximum span for a steel angle beam?

- The maximum span for a steel angle beam depends on various factors such as the load it is intended to support, the dimensions of the beam, and the type of steel being used. It is best to consult engineering tables, codes, or a structural engineer to determine the maximum span for a specific steel angle beam in a given application.

- Q: What are the different types of steel angles used in fencing and gates?

- Fencing and gates commonly utilize several types of steel angles. An example is the equal angle, also known as the L-shaped angle, which has sides of equal length. It is frequently employed for vertical and horizontal bracing in fencing and gates. Another variant is the unequal angle, which features one longer side and one shorter side. This type is often used for diagonal bracing, providing added strength and stability to fencing and gates. The rounded edge angle is another option, replacing sharp corners with rounded edges. This choice is favored in fencing and gates to minimize the risk of injury, as the rounded edges are less likely to cause cuts or other accidents. Additionally, there are slotted angles that come with pre-drilled holes along their length. These holes facilitate the easy attachment of fencing and gate components such as panels or hinges. Finally, galvanized angles are coated with a layer of zinc to safeguard against rust and corrosion. This type is particularly suitable for outdoor fencing and gates, offering long-lasting durability and resistance to the elements. In conclusion, the various types of steel angles used in fencing and gates provide different advantages in terms of strength, stability, safety, ease of installation, and resistance to rust and corrosion. The choice of angle will depend on the specific requirements and preferences of each fencing or gate project.

- Q: What are the load-bearing capacities of steel angles?

- The load-bearing capacities of steel angles vary depending on various factors such as the size and thickness of the angle, the type of steel used, and the specific application. In general, steel angles are designed to provide structural support and can handle significant loads. The load-bearing capacity of a steel angle is determined by its bending strength and its ability to resist compression and tension forces. These factors are influenced by the material properties of the steel, including its yield strength, tensile strength, and ductility. Steel angles are commonly used in construction and engineering projects for applications such as supporting beams, frames, and structures. The load-bearing capacity of a steel angle is often specified by engineers or designers based on the specific requirements of the project and the anticipated loads. To determine the load-bearing capacity of a steel angle, calculations and structural analysis are typically performed using engineering principles and standards. These calculations consider factors such as the angle's dimensions, support conditions, and the expected loads. It is important to consult relevant engineering codes and standards, such as those provided by organizations like the American Institute of Steel Construction (AISC) or British Standards Institution (BSI), to ensure that the load-bearing capacity of a steel angle meets the necessary requirements for a given application. In summary, the load-bearing capacities of steel angles can vary depending on several factors. Consulting with a structural engineer or referring to appropriate engineering standards is crucial to accurately determine the load-bearing capacity of a specific steel angle in a given application.

- Q: 304 what does angle iron stand for?

- 304 stainless steel applications:304 is the most widely used stainless steel, heat-resistant steel. Used in food production equipment, chemical equipment, nuclear energy, etc..

- Q: Are steel angles suitable for use in high-rise buildings?

- Yes, steel angles are suitable for use in high-rise buildings. They are commonly used as structural members in high-rise construction due to their strength, durability, and ability to withstand heavy loads and forces. Steel angles provide excellent support and stability, making them a reliable choice for constructing the framework of high-rise buildings.

- Q: How do you determine the load capacity of a steel angle?

- The load capacity of a steel angle is determined by calculating its moment of inertia and considering factors such as material strength, dimensions, and the type of loading it will be subjected to. Additionally, engineering standards and codes provide guidelines for determining load capacities based on these calculations.

- Q: What are the standard sizes for steel angles?

- The standard sizes for steel angles vary depending on the manufacturer and the specific requirements of the project. However, some commonly available sizes for steel angles include 1/2 inch, 3/4 inch, 1 inch, 1-1/4 inch, 1-1/2 inch, and 2 inches. These sizes refer to the measurement of the sides of the angle.

- Q: What are the different types of steel angles used in storage systems?

- There are several types of steel angles commonly used in storage systems, including equal angles, unequal angles, and L-shaped angles. These angles provide structural support and stability to the storage systems, allowing for efficient and organized storage of various items.

- Q: Can steel angles be used in decorative or architectural applications?

- Yes, steel angles can be used in decorative or architectural applications. Steel angles are versatile and can be shaped and manipulated to create various architectural elements such as decorative trims, ornamental railings, window frames, door frames, and even structural features like support brackets. Additionally, steel angles can be coated or finished in different ways to enhance their aesthetic appeal, such as by painting, powder coating, or patina finishes. Their strength and durability make them suitable for both indoor and outdoor applications, providing structural integrity while also adding a visually appealing element to the design. Overall, steel angles offer a wide range of design possibilities and can be effectively used in decorative or architectural applications.

Send your message to us

Hot Rolled Carbon Steel Equal Angle with Many Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords