Hot Rolled Steel Equal Angle with Many Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Carbon Steel Equal Angle at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Product Advantages:

OKorder's Equal Angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

5.Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: What are the welding techniques used for steel angles?

- Some common welding techniques used for steel angles include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). These techniques are effective in joining steel angles due to their ability to provide strong and durable welds.

- Q: What are the common grades of steel used for angles?

- The specific application and requirements determine the various common grades of steel used for angles. Amongst these, A36, A572-50, and A588 are the most frequently utilized. A36, known for its strength and versatility, is a low carbon steel commonly employed in construction and structural applications. A572-50, on the other hand, is a high-strength, low-alloy steel widely used in structural applications due to its exceptional weldability and formability. In contrast, A588, a high-strength, low-alloy steel, finds its primary use in outdoor applications like bridges and buildings, owing to its excellent corrosion resistance. These grades of steel possess distinct characteristics and properties, enabling diverse applications and ensuring adherence to specific project requirements.

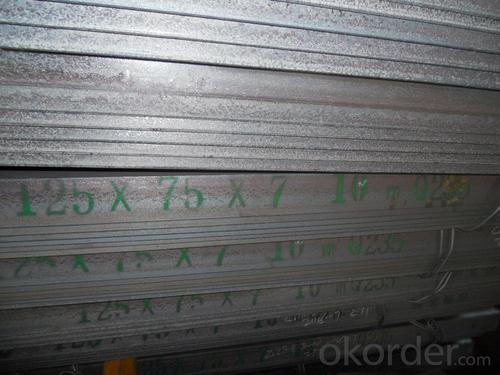

- Q: Angle iron specifications 125 * 80 * 101 m multiple

- Angle iron specifications 125 * 80 * 10 weight: 15.3075kg/m.Angle called angle, the steel strip is perpendicular to each other on both sides into the corner. There are equal angles and unequal angles. The two sides of an equal angle steel are equal in width. The specifications are expressed in millimeters of edge width * edge width * edge thickness. Such as "/ 30 x 30 x 3", that is 30 mm width equal angle, edge thickness of 3 mm. Also available models that model is the number of centimeters wide, such as angle 3#. The model does not mean the size of the different edges and sizes of the same model. Therefore, the width, the edge and the thickness of the angle iron should be filled out in the contract and other documents, so as not to be indicated by the model alone. Standard Specification for hot-rolled equal angle iron is 2#-20#. The angle iron can be made up of different force components according to the different structure, and can also be used as the connecting piece between the components. Widely used in a variety of architectural and engineering structures, such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reaction tower, container frame and warehouse.

- Q: Can steel angles be used for framing or supporting mezzanines or elevated platforms?

- Yes, steel angles can be used for framing or supporting mezzanines or elevated platforms. Steel angles are commonly used in construction projects for their structural strength and versatility. They are often used as supports or braces in various applications, including framing mezzanines or elevated platforms. Steel angles provide stability and structural integrity, making them an ideal choice for supporting heavy loads and creating a robust framework. Their L-shaped design allows for easy installation and provides excellent resistance against bending and shearing forces. Additionally, steel angles can be easily welded or bolted together, offering flexibility in design and construction. Overall, steel angles are a reliable and effective choice for framing or supporting mezzanines or elevated platforms.

- Q: What are the cost considerations for using steel angles?

- There are several cost considerations to take into account when using steel angles. Firstly, the cost of the steel material itself can vary depending on the grade and quality of the steel. Higher-grade steel angles tend to be more expensive, but they offer better strength and durability. Additionally, the length and size of the steel angles will affect the overall cost. Longer and larger angles will generally be more expensive due to the increased amount of steel required. It is important to carefully assess the required dimensions to avoid unnecessary costs. Another cost consideration is the fabrication and finishing of the steel angles. If custom fabrication or special finishing techniques are required, such as welding, cutting, or painting, these processes can add to the overall cost. It is essential to factor in these additional expenses when budgeting for the use of steel angles. Transportation costs should also be considered. Steel angles are heavy and bulky, which can lead to higher shipping costs, especially for long distances. It is crucial to account for these expenses, particularly if the project requires a significant quantity of steel angles. Lastly, it is important to consider the long-term costs associated with steel angles. While steel is durable and long-lasting, it may require maintenance or protective coatings to prevent corrosion over time. These maintenance costs should be factored into the overall budget to ensure the longevity and reliability of the steel angles. Overall, the cost considerations for using steel angles include the price of the steel material, the dimensions and size of the angles, fabrication and finishing processes, transportation expenses, and long-term maintenance costs. Evaluating and planning for these factors will help ensure a cost-effective and successful use of steel angles in various applications.

- Q: How do you determine the center of gravity for a steel angle?

- To determine the center of gravity for a steel angle, you need to consider its shape and dimensions. The center of gravity is the point where the weight of the object is evenly distributed, and finding this point is crucial for understanding its stability and balance. First, measure the length, width, and thickness of the steel angle. These measurements will help you calculate the area and volume of the angle, which are essential for determining the center of gravity. Next, locate the centroid of the steel angle. The centroid is the geometric center of the object, and it represents the point where all the weight is concentrated. For a symmetrical steel angle, the centroid will be at the intersection of the two axes of symmetry. However, if the angle is asymmetrical, finding the centroid might require more complex calculations. To calculate the centroid, use the formulas for the area moment of inertia. These formulas depend on the shape of the angle. For example, if the angle is a simple L-shape, the centroid can be determined by finding the average of the coordinates of the two legs' centroids. Once you have determined the centroid, you can then locate the center of gravity. The center of gravity coincides with the centroid of the steel angle in uniform density objects. However, for objects with non-uniform density, additional calculations might be required to account for variations in weight distribution. In summary, determining the center of gravity for a steel angle involves measuring its dimensions, calculating the centroid based on its shape, and then locating the center of gravity. This information is crucial for understanding the angle's stability and balance, especially in applications where it will be subjected to external forces or loads.

- Q: Are steel angles suitable for use in high-rise buildings?

- Yes, steel angles are suitable for use in high-rise buildings. Steel angles are commonly used as structural elements in high-rise buildings due to their excellent strength, durability, and versatility. They are able to withstand heavy loads and provide structural support, making them ideal for use in beams, columns, and bracing systems. Steel angles can be easily fabricated and installed, allowing for efficient construction processes. Additionally, steel angles can be designed in various sizes and shapes to meet specific structural requirements, providing flexibility in design and construction. Overall, steel angles are a reliable and cost-effective choice for high-rise buildings as they offer the necessary strength and stability required for such structures.

- Q: How do you calculate the weight-bearing capacity of a steel angle?

- To calculate the weight-bearing capacity of a steel angle, you need to consider its dimensions, material properties, and loading conditions. The weight-bearing capacity can be calculated using engineering formulas and techniques such as the Euler formula or the AISC Manual. These calculations take into account factors like the cross-sectional area, moment of inertia, and the applied loads to determine the maximum load the steel angle can support without failure.

- Q: Are steel angles corrosion-resistant?

- Steel angles can be corrosion-resistant depending on the type of steel used and the presence of protective coatings. Stainless steel angles, for example, are highly corrosion-resistant due to their high chromium content. This alloy forms a passive layer on the surface that protects against corrosion. Additionally, galvanized steel angles are coated with a layer of zinc, which provides excellent corrosion protection. However, untreated carbon steel angles are not corrosion-resistant and can rust if exposed to moisture or corrosive environments. Therefore, it is important to consider the specific type of steel and any additional protective measures when determining the corrosion resistance of steel angles.

- Q: Can steel angles be used as supports for mechanical or electrical equipment?

- Indeed, mechanical or electrical equipment can be supported by steel angles. Due to their versatility and strength, steel angles are apt for a diverse array of uses. They offer stability, rigidity, and support, effectively securing mechanical or electrical equipment. The L-shaped configuration of steel angles facilitates effortless attachment and installation, rendering them convenient for a multitude of mounting necessities. Moreover, steel angles can be readily tailored and fabricated to fulfill precise specifications, guaranteeing a dependable and trustworthy support system for the equipment.

Send your message to us

Hot Rolled Steel Equal Angle with Many Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords