Hot Rolled Steel Equal Angle with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Carbon Steel Equal Angle at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Product Advantages:

OKorder's Equal Angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

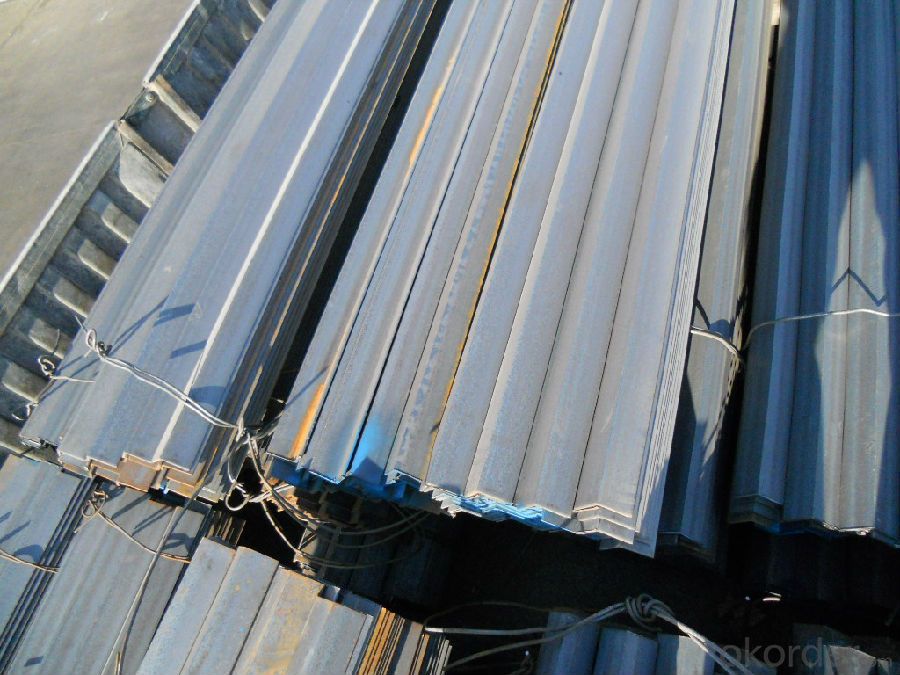

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: Are steel angles suitable for window frames?

- Yes, steel angles are suitable for window frames. Steel angles are often used in construction for their strength and durability, making them an ideal choice for supporting the weight of window frames. They provide excellent structural support, ensuring that the window frames remain stable and secure. Additionally, steel angles are resistant to corrosion, which is particularly advantageous for window frames that are exposed to external elements such as rain and humidity. Furthermore, steel angles can be easily fabricated and customized to meet specific design requirements, making them a versatile option for window frame construction. Overall, steel angles offer numerous benefits that make them a suitable choice for window frames in terms of strength, durability, corrosion resistance, and flexibility.

- Q: What are the different methods of surface painting for steel angles?

- There exists a variety of techniques for surface painting steel angles, each offering distinct advantages and considerations. 1. Brushing: The most commonly employed method for surface painting steel angles involves the manual application of paint using a brush. Brushing provides excellent control and precision, making it well-suited for smaller projects or touch-ups. However, it may not be as efficient for larger-scale applications. 2. Spraying: When a large area needs to be painted quickly, spraying is a popular technique for painting steel angles. It involves the even distribution of paint onto the surface using a paint spray gun or aerosol canister. Spraying results in a smooth and uniform finish, but proper safety precautions, such as wearing a mask and ensuring adequate ventilation, are necessary. 3. Dipping: In this method, steel angles are immersed in a tank or container filled with paint. Dipping ensures complete coverage and is often utilized in high-volume production processes. However, it may not be suitable for angles with intricate designs or complex shapes, as excess paint may drip or accumulate unevenly. 4. Electrostatic painting: Electrostatic painting involves charging the paint particles and applying them to a grounded steel angle. This creates an electromagnetic attraction, resulting in an even and efficient coverage. This technique is commonly employed in industrial settings and aids in reducing paint waste and overspray. 5. Powder coating: Powder coating is a dry finishing process that entails the application of a fine powder onto the surface of a steel angle. The powder is then heated and fused onto the metal, creating a durable and visually appealing finish. Powder coating offers excellent corrosion resistance and can be done in a variety of colors and textures. However, specialized equipment is required, and it may not be suitable for small-scale or on-site applications. When selecting a surface painting method for steel angles, careful consideration must be given to factors such as project size and complexity, desired finish quality, environmental conditions, and available resources. Seeking guidance from a professional painter or coating specialist can help determine the most appropriate method for a specific application.

- Q: Can steel angles be used in the construction of shopping malls?

- Shopping malls can indeed incorporate steel angles in their construction. These versatile structural components offer support and stability to different parts of a building, such as shopping malls. The construction industry often employs steel angles for framing, bracing, and reinforcing structures. Their usage extends to supporting the walls, roof, and floors of shopping malls, thereby guaranteeing the building's structural integrity. Moreover, they come in handy when constructing staircases, escalators, and mezzanines within the shopping mall. The inclusion of steel angles in shopping mall construction presents numerous benefits, including their durability, strength, and cost-effectiveness.

- Q: Can steel angles be used for supporting mechanical equipment?

- Yes, steel angles can be used for supporting mechanical equipment. Steel angles are commonly used in construction and engineering projects for their strength, durability, and versatility. They provide a stable and rigid support structure for various types of mechanical equipment, including heavy machinery, conveyors, and support frames. Steel angles are known for their load-bearing capacity, which makes them ideal for providing structural support in industrial applications. Additionally, their L-shaped design allows for easy installation and attachment of equipment. Overall, steel angles are a reliable and commonly used choice for supporting mechanical equipment due to their strength, durability, and ease of use.

- Q: How do you calculate the shear force on a loaded steel angle?

- In order to determine the shear force on a loaded steel angle, one must take into account the applied load, the angle's geometry, and the steel's material properties. The term "shear force" refers to the force that acts parallel to the angle's cross-sectional area. Firstly, it is crucial to ascertain the applied load that is acting upon the steel angle. This load can be either concentrated, distributed, or a combination of both. It is of utmost importance to accurately determine the load's magnitude and location. Subsequently, the steel angle's geometry should be considered. The angle consists of two legs, each possessing specific measurements of length, width, and thickness. Precise measurements of these dimensions are necessary. Once the load and angle dimensions are obtained, the shear force can be calculated by employing the following formula: Shear Force = Load / Cross-sectional Area To calculate the cross-sectional area, one must take into account the angle's shape. Typically, the cross-sectional area of a steel angle is calculated by adding together the areas of both legs and then subtracting the area of the corner radius. In the case of unequal legs, the cross-sectional area can be calculated by adding together the areas of the longer and shorter legs and subtracting the area of the corner radius. After determining the cross-sectional area, divide the applied load by this value to determine the shear force acting on the loaded steel angle. It is important to note that the aforementioned calculation assumes that the steel angle is solely subjected to pure shear. In practical scenarios, additional factors such as bending moments and torsion may need to be taken into consideration, which would necessitate more intricate calculations and analysis. Therefore, it is advisable to consult relevant design codes, principles of structural engineering, or seek the guidance of a professional engineer for accurate and reliable results.

- Q: Can steel angles be welded?

- Yes, steel angles can be welded. Welding is a commonly used method to join steel angles together. It involves heating the steel angles to a high temperature and then applying a filler material, usually in the form of a welding rod or wire, to create a strong bond between the angles. Welding provides a secure and durable connection between steel angles, making it suitable for various applications in construction, manufacturing, and other industries.

- Q: How do you calculate the bending capacity of a steel angle?

- To calculate the bending capacity of a steel angle, you need to determine the moment of inertia of the angle section and the maximum allowable stress. The moment of inertia is calculated using the dimensions of the angle section, and the maximum allowable stress is typically provided by the steel manufacturer. By applying these values to the appropriate bending equation, you can calculate the bending capacity of the steel angle.

- Q: Can steel angles be used in the construction of theatres?

- The utilization of steel angles in theatre construction is indeed possible. Their strength and versatility make them common structural components in construction. They offer stability and support, making them suitable for various theatre construction applications. Steel angles can be employed in theatres to establish the framework for stage platforms, catwalks, and balconies. They can also be used to support lighting fixtures, rigging systems, and sound equipment. Additionally, they can reinforce the structural integrity of the theatre building itself, such as beams, columns, and trusses. The advantages of using steel angles in theatre construction are plentiful. Firstly, steel is a durable and long-lasting material, ensuring the stability and safety of the theatre structure over time. Moreover, steel angles can be easily customized and fabricated to meet specific design requirements, allowing for flexibility in theatre construction. Furthermore, steel angles possess fire-resistant properties, which are of utmost importance in theatre environments where fire safety is a priority. They can withstand high temperatures and provide structural support even in the event of a fire, guaranteeing the safety of both the building and its occupants. Overall, steel angles are an excellent choice for theatre construction due to their strength, versatility, and fire-resistant properties. They furnish the necessary structural support and stability required for the unique needs of theatre spaces, ensuring a safe and functional environment for performances and audiences alike.

- Q: Do steel angles require any special maintenance?

- No special maintenance is needed for steel angles, but their lifespan can be prolonged with proper care and attention. It is recommended to regularly clean them to remove dirt, debris, and corrosive substances. Additionally, it is important to promptly address any signs of rust, cracks, or damage to prevent further deterioration. To prevent corrosion and extend the life of the steel angles, applying a protective coating or paint is advisable. In general, steel angles require minimal maintenance, but regular inspections and maintenance practices are crucial for optimal performance and longevity.

- Q: What are the different surface coating options for steel angles?

- Some different surface coating options for steel angles include galvanization, powder coating, and painting.

Send your message to us

Hot Rolled Steel Equal Angle with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords