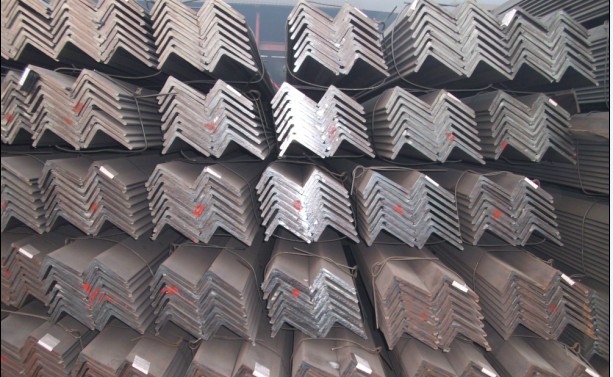

Hot rolled angle steel GB Q235 or Q345B or equivalent

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications

angle steel

1.size:25*16*3mm-200*125*18mm

2.quality:Q235,Q345,SS400,A36

3.length: 6m, 9m, 12m

4.unequal

angle steel

angle steel

(1)Material:Q235 SS400 S235JR OR ST37-2 Q345

(2)Size:25x16x3mm-200x125x18mm

(3)Certificate:ISO,CE

agle steel

angle steel

Angle called angle, the steel strip is perpendicular to each other on both sides into angular.Divided into equilateral angle steel and ranging from side angle. Two equilateral angle steel edge width is the same. The specification is expressed by edge width * width * thick edgenumber of millimeters. Such as "/ 30 x 30 x 3", namely that equilateral angle steel edge widthof 30 mm, 3 mm thick edge. Can also be used to model representation, model is the wideangle 3# cm, such as. The model does not represent the same type in different edge thickness size, thus in the contract and other documents on the angle of the edge width, edgethick size fill in complete, avoid alone represented by type. Hot rolled equilateral angle steelspecifications for 2#-20#. Angle according to the different needs of structure composed of a variety of stress components, can also be used as a component of the connections between the. Widely used in a variety of architectural and engineering structures, such as beams,bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reactor,container frame and warehouse.

Mainly divided into equilateral angle steel, equilateral angle steel two categories, includingunequal angle can be divided into equal thickness and unequal thickness ranging from two.

Angle specifications with the side length of the size and edge thickness. At present, the domestic steel specifications for 2 - 20 cm in length, number of numbers, the same horn steel often have 2 - 7 different edge thickness. The actual size and inlet angle marked on both sides of the thickness and indicate the relevant standards. The general length of more than 12.5cm for large angle steel, 12.5cm - 5cm for the medium angle, length of 5cm for smallangle.

Inlet and outlet angle steel orders generally required the use specifications in the steel,carbon structural steel grades as appropriate. Is the angle in addition to standard number, nospecific composition and performance series.

Angle steel delivery length is divided into fixed length, size two, domestic steel length range is3 - 9m, 4 12M, 4 19m, 6 19m four range according to different specifications. Japanese steellength ranges from 6 to 15m.

Section of unequal angle height according to the long edge of the width to calculate the non equilateral angle steel. Refer to section angle and side length is not equal to the steel. Is a kind of angle steel. The length from 25mm * 16mm to 200mm * l25mm. By the hot rolling mill rolling in. General scalene angle steel specifications: thickness of 4-18mm / 50*32-- / 200*125

Equilateral angle steel is widely used in all kinds of metal structures, bridges, machinery manufacturing and shipbuilding industry, all kinds of architectural and engineering structures,such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace,reactor, container frame and warehouse etc.

1.Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2.With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q: Can steel angles be used as supports for beams or columns?

- Yes, steel angles can be used as supports for beams or columns. Steel angles provide structural support and are commonly used in construction to provide stability and reinforcement for beams and columns. They are known for their strength and durability, making them suitable for bearing heavy loads and providing structural integrity to the overall structure.

- Q: Can steel angles be used for machine guards?

- Yes, steel angles can be used for machine guards. Steel angles are commonly used in the construction industry for their strength and durability. They can be easily fabricated and installed to create a protective barrier around machinery, ensuring the safety of workers and preventing accidents. The versatility of steel angles allows them to be customized to fit various machine sizes and shapes. Additionally, steel angles offer good impact resistance and can withstand heavy loads, making them suitable for use in machine guarding applications.

- Q: What are the different testing methods for steel angles?

- There are several testing methods for steel angles, including visual inspection, dimensional measurement, hardness testing, chemical analysis, and mechanical testing. Visual inspection involves examining the angles for any visual defects or irregularities. Dimensional measurement ensures that the angles meet the specified size and shape requirements. Hardness testing determines the hardness of the steel, which is an important factor in its strength and durability. Chemical analysis is performed to check the composition and purity of the steel, ensuring that it meets the required standards. Mechanical testing involves subjecting the steel angles to various loads and stresses to evaluate their mechanical properties such as strength and ductility.

- Q: Can steel angles be used for reinforcement in concrete structures?

- Yes, steel angles can be used for reinforcement in concrete structures. Steel angles, also known as L-shaped steel profiles, are commonly used as reinforcing bars in concrete construction. They provide increased strength and stability to the concrete structure, especially in areas where additional support is needed. Steel angles are typically placed within the concrete forms, ensuring proper alignment and spacing, and then embedded in the concrete during the pouring process. This reinforcement helps to prevent cracking and enhance the overall structural integrity of the concrete structure. Steel angles are versatile and can be used in various concrete applications, such as beams, columns, walls, and slabs.

- Q: How do you determine the load-bearing capacity of a steel angle?

- To determine the load-bearing capacity of a steel angle, several factors need to be considered. Firstly, the material properties of the steel angle must be known, such as its yield strength and ultimate tensile strength. These values can be obtained from the manufacturer or from relevant material standards. Next, the dimensions and shape of the steel angle play a crucial role in determining its load-bearing capacity. The angle's thickness, width, and length should be measured accurately. Additionally, the angle's shape, whether it is equal or unequal, must also be taken into account. Once these properties are known, the load-bearing capacity can be calculated using engineering principles and structural analysis methods. One common approach is to use the Euler's formula, which considers the bending and axial loads on the steel angle. The Euler's formula states that the load-bearing capacity of a steel angle is proportional to its moment of inertia and the modulus of elasticity. These values are calculated based on the dimensions and shape of the angle. Furthermore, other factors such as the angle's end supports, the type of loading (e.g., concentrated load or uniformly distributed load), and any additional factors of safety must be taken into consideration. It is important to note that determining the load-bearing capacity of a steel angle is a complex process that requires expertise in structural engineering. Therefore, it is recommended to consult with a qualified engineer or refer to relevant design codes and standards to ensure accurate and safe calculations.

- Q: What are the different finishes available for steel angles?

- There are several different finishes available for steel angles, including hot-dip galvanized, mill finish, painted, and powder coated.

- Q: Can steel angles be used for support structures in sports arenas or stadiums?

- Yes, steel angles can be used for support structures in sports arenas or stadiums. Steel angles are commonly used in construction due to their strength, versatility, and cost-effectiveness. They provide excellent support and stability, making them suitable for various structural applications, including supporting the weight of sports arenas or stadiums.

- Q: Are steel angles available in custom sizes?

- Custom sizes of steel angles are indeed available. In the construction and manufacturing sectors, steel angles are widely used and are available in a variety of standard sizes. However, if the standard sizes do not meet the specific needs of a project, it is possible to manufacture custom sizes. This provides greater flexibility when designing and constructing structures or products. Custom-sized steel angles can be created by either cutting and reshaping standard angles or by manufacturing them from scratch to match the desired dimensions.

- Q: Can steel angles be used for load-bearing walls?

- Yes, steel angles can be used for load-bearing walls. Steel angles are commonly used in construction as a structural element to provide support and stability. They are often used to reinforce load-bearing walls by adding strength and rigidity. Steel angles can be used to distribute the weight of a load evenly, making them suitable for load-bearing applications. However, it is important to ensure that the steel angles are appropriately designed and installed to meet the specific load requirements of the wall. Consulting with a structural engineer or construction professional is recommended to ensure the proper use of steel angles for load-bearing walls.

- Q: Can steel angles be used for pipe supports?

- Yes, steel angles can be used for pipe supports. Steel angles provide structural strength and stability, making them suitable for supporting pipes and ensuring their stability and alignment.

Send your message to us

Hot rolled angle steel GB Q235 or Q345B or equivalent

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords