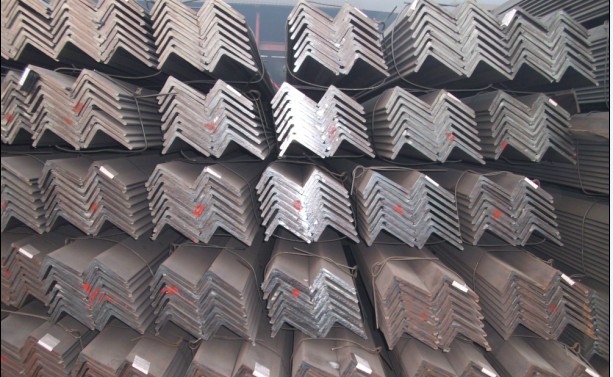

Hot rolled angle steel ASTM A36 or GB Q235 20-250mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:Specificationsangle steel angle steel angle steel agle steel angle steel

Angle called angle, the steel strip is perpendicular to each other on both sides into angular.Divided into equilateral angle steel and ranging from side angle. Two equilateral angle steel edge width is the same. The specification is expressed by edge width * width * thick edgenumber of millimeters. Such as "/ 30 x 30 x 3", namely that equilateral angle steel edge widthof 30 mm, 3 mm thick edge. Can also be used to model representation, model is the wideangle 3# cm, such as. The model does not represent the same type in different edge thickness size, thus in the contract and other documents on the angle of the edge width, edgethick size fill in complete, avoid alone represented by type. Hot rolled equilateral angle steelspecifications for 2#-20#. Angle according to the different needs of structure composed of a variety of stress components, can also be used as a component of the connections between the. Widely used in a variety of architectural and engineering structures, such as beams,bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reactor,container frame and warehouse. Mainly divided into equilateral angle steel, equilateral angle steel two categories, includingunequal angle can be divided into equal thickness and unequal thickness ranging from two. Angle specifications with the side length of the size and edge thickness. At present, the domestic steel specifications for 2 - 20 cm in length, number of numbers, the same horn steel often have 2 - 7 different edge thickness. The actual size and inlet angle marked on both sides of the thickness and indicate the relevant standards. The general length of more than 12.5cm for large angle steel, 12.5cm - 5cm for the medium angle, length of 5cm for smallangle. Inlet and outlet angle steel orders generally required the use specifications in the steel,carbon structural steel grades as appropriate. Is the angle in addition to standard number, nospecific composition and performance series. Angle steel delivery length is divided into fixed length, size two, domestic steel length range is3 - 9m, 4 12M, 4 19m, 6 19m four range according to different specifications. Japanese steellength ranges from 6 to 15m. Section of unequal angle height according to the long edge of the width to calculate the non equilateral angle steel. Refer to section angle and side length is not equal to the steel. Is a kind of angle steel. The length from 25mm * 16mm to 200mm * l25mm. By the hot rolling mill rolling in. General scalene angle steel specifications: thickness of 4-18mm / 50*32-- / 200*125 Equilateral angle steel is widely used in all kinds of metal structures, bridges, machinery manufacturing and shipbuilding industry, all kinds of architectural and engineering structures,such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace,reactor, container frame and warehouse etc. 1.Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load. 2.With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request. 3. Marks: Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port. Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer. If loading by container the marking is not needed, but we will prepare it as customer request. |

- Q: Can steel angles be cut to size?

- Yes, steel angles can be cut to size using various cutting tools and techniques such as sawing, shearing, or plasma cutting.

- Q: How do steel angles behave under seismic forces?

- Steel angles behave differently under seismic forces depending on their design, size, and connection details. Generally, steel angles are commonly used in seismic-resistant structures due to their ability to dissipate energy and resist lateral forces. Here are some key characteristics of how steel angles behave under seismic forces: 1. Ductility: Steel angles exhibit high ductility, which allows them to undergo large deformations without failure. This property is crucial in seismic design as it allows the structure to absorb and dissipate energy during an earthquake, preventing sudden collapse. 2. Flexibility: Steel angles have the ability to flex and bend under seismic forces, allowing them to absorb energy and reduce the impact on the overall structure. This flexibility helps in distributing the seismic forces throughout the structure, minimizing localized damage. 3. Connection behavior: Proper connection design is crucial to ensure the performance of steel angles under seismic forces. The connections should be designed to allow for rotation and accommodate the expected displacements during an earthquake. Adequate connections prevent the angles from becoming brittle or failing prematurely. 4. Buckling resistance: Steel angles are susceptible to buckling under compression forces. To enhance their buckling resistance, lateral bracing or stiffeners are often used. These elements provide additional support to the angles and help prevent buckling during seismic events. 5. Strength and stiffness: Steel angles have high strength and stiffness, which allows them to resist the lateral forces induced by an earthquake. The strength of steel angles can be enhanced through proper material selection, such as using higher-grade steel with greater yield strength. Overall, steel angles are well-suited for seismic-resistant structures due to their ductility, flexibility, and strength. However, their behavior under seismic forces heavily relies on proper design, connection details, and adherence to seismic codes and standards. It is essential to consult with structural engineers and follow best practices to ensure the optimal performance of steel angles in seismic design.

- Q: How to determine the neutral axis of the angle bar?

- For the bolt group, the calculation of the location of the neutral axis is more complex, and is usually approximately assumed on the bottom row of the bolt axis.

- Q: How are steel angles protected against corrosion?

- Steel angles are protected against corrosion through various methods such as galvanization, painting, or applying a protective coating. These protective measures create a barrier between the steel surface and corrosive elements, preventing direct contact and ensuring the longevity and durability of the steel angles.

- Q: Are steel angles suitable for historical restoration projects?

- Yes, steel angles can be suitable for historical restoration projects. They offer excellent strength and durability, which is useful for structural support and reinforcement. Additionally, steel angles can be easily fabricated to match the original design and can be finished to closely resemble the aesthetic of historical materials. However, careful consideration should be given to the specific project requirements and the preservation of historical integrity.

- Q: Do steel angles come with any warranties?

- Indeed, warranties are usually included with steel angles. The particular terms of the warranty may differ contingent upon the manufacturer or supplier. Nevertheless, reputable companies commonly provide warranties to guarantee the excellence and functionality of their steel angles. These warranties generally encompass flaws in materials or workmanship and can span from a few months to numerous years. It is prudent to review the manufacturer or supplier's warranty terms and conditions prior to acquiring steel angles to comprehend the scope and duration of the warranty coverage.

- Q: What are the different grades of steel angles?

- There are several different grades of steel angles, each with its own unique properties and characteristics. Some of the most commonly used grades include A36, A572, and A588. A36 steel angle is the most commonly used grade and is known for its high strength and versatility. It has a minimum yield strength of 36,000 psi, making it suitable for a wide range of applications. A36 steel angle is often used in construction projects, as well as for structural support in buildings and bridges. A572 steel angle is another popular grade, known for its superior strength and durability. It has a minimum yield strength of 50,000 psi, making it ideal for heavy-duty applications. A572 steel angle is commonly used in construction projects requiring high strength, such as in the construction of skyscrapers and large buildings. A588 steel angle is a corrosion-resistant grade that is often used in outdoor and marine environments. It has a minimum yield strength of 50,000 psi and is designed to withstand exposure to harsh weather conditions and corrosive elements. A588 steel angle is commonly used in coastal areas, as well as in the construction of bridges and other structures exposed to saltwater or high humidity. These are just a few examples of the different grades of steel angles available. The choice of grade depends on the specific application and the required properties, such as strength, corrosion resistance, and durability. It is important to consult with a professional or refer to industry standards when selecting the appropriate grade of steel angle for a particular project.

- Q: How do you calculate the moment of inertia of a steel angle?

- To calculate the moment of inertia of a steel angle, you need to know the dimensions and shape of the angle. The moment of inertia measures an object's resistance to changes in rotation, and it is essential in engineering and physics calculations. The moment of inertia, denoted by I, can be calculated using the formula: I = (b * h^3) / 12 Where: - I is the moment of inertia - b is the base width of the steel angle - h is the height or leg length of the steel angle This formula assumes that the steel angle is a uniform, solid object. If the steel angle has varying dimensions or holes, the calculation becomes more complex and may require additional formulas or numerical methods. It is important to note that the moment of inertia depends on the axis of rotation. The formula mentioned above calculates the moment of inertia about the centroidal axis, which is the axis passing through the center of mass of the angle. If you need to calculate the moment of inertia about a different axis, you may need to use the parallel axis theorem or other advanced techniques. In practice, it is often helpful to consult engineering handbooks or reference materials specific to steel angles as they may provide more detailed formulas or tables that take into account specific design characteristics and dimensions.

- Q: Can steel angles be used for manufacturing door frames?

- Yes, steel angles can be used for manufacturing door frames. Steel angles provide stability, strength, and durability, making them suitable for supporting and reinforcing door frames.

- Q: What are the different types of steel angles used in automotive engineering?

- Automotive engineering relies on various types of steel angles for structural strength, stability improvement, and overall vehicle performance and safety. Below are some examples of the steel angles frequently employed in this field: 1. Unequal angles, also known as L-angles, provide essential support and reinforcement in automotive engineering. These angles possess different lengths on each side, facilitating easy welding or bolting onto various vehicle chassis or frame components. 2. Tee angles, or T-angles, are commonly used to join two components at a right angle. Their flat base and vertical stem design ensures stability and secure attachment of different vehicle parts. 3. Channel angles, or C-angles, play a significant role in forming vehicle structures. With their U-shaped cross-section, they are often utilized in the creation of structural components like door frames, roof rails, and chassis reinforcements. 4. Z-bar angles, or Z-angles, are widely applied to enhance strength and rigidity in automotive structures. Their Z-shaped cross-section effectively resists bending and torsional forces, making them suitable for suspension systems, roll bars, and body components. 5. U-bar angles, or U-angles, offer support and reinforcement to various vehicle components. Their U-shaped cross-section is frequently employed in the creation of bumper beams, frame reinforcements, and roll cage bars. These examples highlight the diverse applications of steel angles in automotive engineering. Each angle possesses unique properties and is selected based on the vehicle design requirements and desired structural integrity.

Send your message to us

Hot rolled angle steel ASTM A36 or GB Q235 20-250mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords