Berkley Jensen Hot Rolled Aluminum Alloy Roofing Sheet with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Hot Rolled Aluminum Alloy Roofing Sheet Description:

Hot Rolled Aluminum Alloy Roofing Sheet is produced advanced technology. Selecting qualified materials and the products have been tested and approved by National Test and Inspection Center for Building Materials, and also tested and approved by European and American Quality Testing System, in accordance with GB/T17748-1999 standards. As one of the international famous brands, IDEABOND developed and researched new products on the basis of aluminum-plastic plate, including fireproof aluminum-plastic composite plate, titanium zinc composite plate, titanium compound plate and stainless steel composite plate etc.

2.Main Features of Hot Rolled Aluminum Alloy Roofing Sheet:

Good Corrosion Resistance

Good Machinability

High Quality

Competitive Price

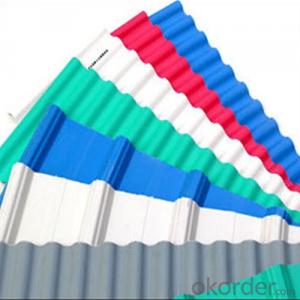

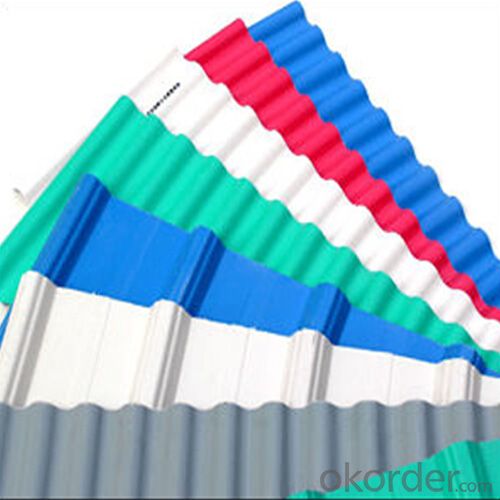

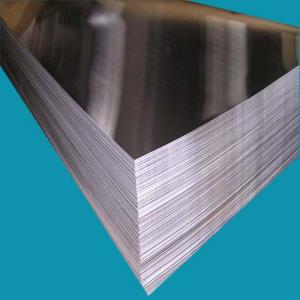

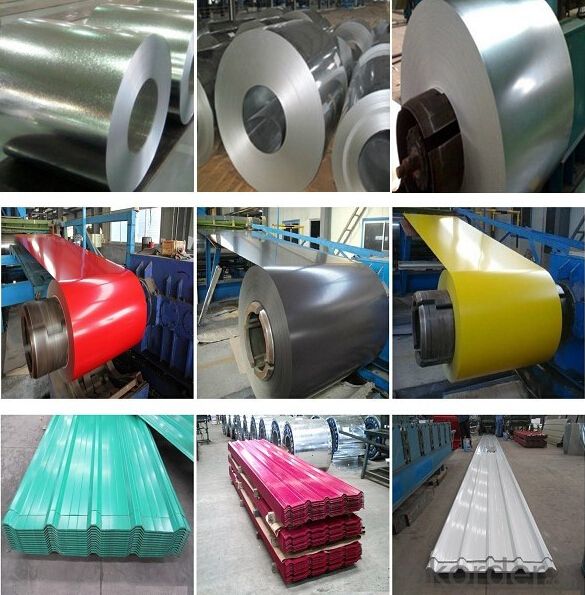

3. Hot Rolled Aluminum Alloy Roofing Sheet Images:

4. Hot Rolled Aluminum Alloy Roofing Sheet Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Can 101 aluminum sheets be embossed or textured?

- Yes, 101 aluminum sheets can be embossed or textured. Aluminum is a versatile material that can be easily manipulated and shaped. Embossing or texturing aluminum sheets involves applying pressure or heat to create raised or recessed patterns on the surface. This process can be done with various techniques, such as mechanical embossing or chemical etching. As long as the aluminum sheets are of good quality and thickness, they can be embossed or textured to achieve desired designs and patterns.

- Q: Can aluminum sheets be perforated?

- Yes, aluminum sheets can be perforated. Perforation is a process that involves punching holes or creating a pattern of holes in a material. Aluminum is a versatile and malleable metal that can be easily perforated using various methods such as punching, drilling, or laser cutting. Perforating aluminum sheets can serve multiple purposes such as allowing for airflow, reducing weight, enhancing aesthetics, or creating filtration systems. The size, shape, and arrangement of the perforations can be customized to meet specific requirements and design preferences. Overall, aluminum sheets can be effectively perforated to enhance their functionality and visual appeal.

- Q: How do aluminum sheets perform in terms of thermal expansion?

- Aluminum sheets have a relatively high coefficient of thermal expansion, meaning they expand significantly when exposed to heat and contract when cooled. This property can be both advantageous and challenging depending on the application, as it allows for easy shaping and forming but may also cause dimensional changes and potential structural issues under extreme temperature fluctuations.

- Q: Are the aluminum sheets suitable for manufacturing lightweight structures?

- Yes, aluminum sheets are highly suitable for manufacturing lightweight structures due to their low density and high strength-to-weight ratio.

- Q: This question asks if aluminum sheets can be recycled repeatedly without losing their quality.

- <p>Yes, aluminum sheets can be recycled multiple times without losing their quality. Aluminum is a highly recyclable material, and the recycling process does not degrade the material's properties. In fact, recycled aluminum requires significantly less energy to produce compared to mining and refining new aluminum from bauxite ore. This makes aluminum recycling an environmentally friendly and cost-effective process, contributing to sustainability and reducing the demand for raw materials.</p>

- Q: I saw a nice looking set of cast aluminum pots for a very good price. They feel very heavy. But I remember hearing that aluminum is not healthy so I am wary of buying them. Any advice would be appreciated.

- A lot of aluminum pots these days have a teflon coating. If the pot is plastic-coated, then you won't get any aluminum from it Twenty years ago, there were concerns about aluminum pots because of the aluminum content of alzheimer clumps. But aluminum intake was cleared from worries about alzheimer -- the clumps gather aluminum rather than vice versa. I'm not aware of any more recent health concerns. The first link below claims that the anodizing process that hardens the surface of the pot, also locks in the metal so that none gets into the food. In the second link, Planet Grean (part of Discovery Channel) says that you're allowed 50 milligrams per day, and even using non-anodized aluminum cookware would give you five or six. But they say not to cook acidic foods, store food in the pot, or keep using the pot after a major scratch in the hardened surface. In the third link, Treehugger (also part of the Discovery empire) says that you get more aluminum from your drinking water than from aluminum cookware. (Alum is used to settle sediment in big-city water supplies.)

- Q: Is aluminum sheet magnetic?

- Incorrect, aluminum sheets lack magnetic properties. As a non-magnetic metal, aluminum neither attracts nor repels magnetic materials due to the absence of magnetic elements within its composition. Consequently, attempting to affix a magnet onto an aluminum sheet will prove futile, as it remains unaffected by magnetic fields.

- Q: This question asks for the duration aluminum sheets can last and how their lifespan compares to other materials.

- <p>The lifespan of aluminum sheets can vary depending on the environment and usage, but generally, they can last for several decades with proper care and maintenance. Aluminum's resistance to corrosion and weathering makes it a durable choice. Compared to other materials, aluminum is more durable than wood and many plastics, but it may not last as long as some high-quality stainless steels or certain types of stone. It's also lighter than steel, making it a popular choice for construction and manufacturing applications where weight is a concern.</p>

- Q: How do aluminum sheets compare to steel sheets in terms of strength?

- Aluminum sheets and steel sheets differ in terms of strength. Steel is generally stronger than aluminum, as it has a higher tensile strength, meaning it can withstand greater forces without breaking or deforming. Steel sheets are commonly used in applications that require high strength and durability, such as construction, automotive manufacturing, and aerospace. On the other hand, aluminum sheets offer a good balance between strength and weight. While aluminum is not as strong as steel, it is significantly lighter, which makes it advantageous in certain applications where weight reduction is a priority, such as the manufacturing of aircraft and vehicles. Additionally, aluminum sheets have excellent corrosion resistance, making them suitable for outdoor or marine environments. Ultimately, the choice between aluminum and steel sheets depends on the specific requirements of the application, considering factors like strength, weight, durability, and corrosion resistance.

- Q: What is aluminum sheet?

- Aluminum sheet refers to a thin, flat piece of aluminum that is commonly used in various industries for its lightweight, durable, and corrosion-resistant properties. It can be easily bent, cut, and formed into different shapes, making it versatile for applications such as construction, automotive, aerospace, and packaging.

Send your message to us

Berkley Jensen Hot Rolled Aluminum Alloy Roofing Sheet with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords