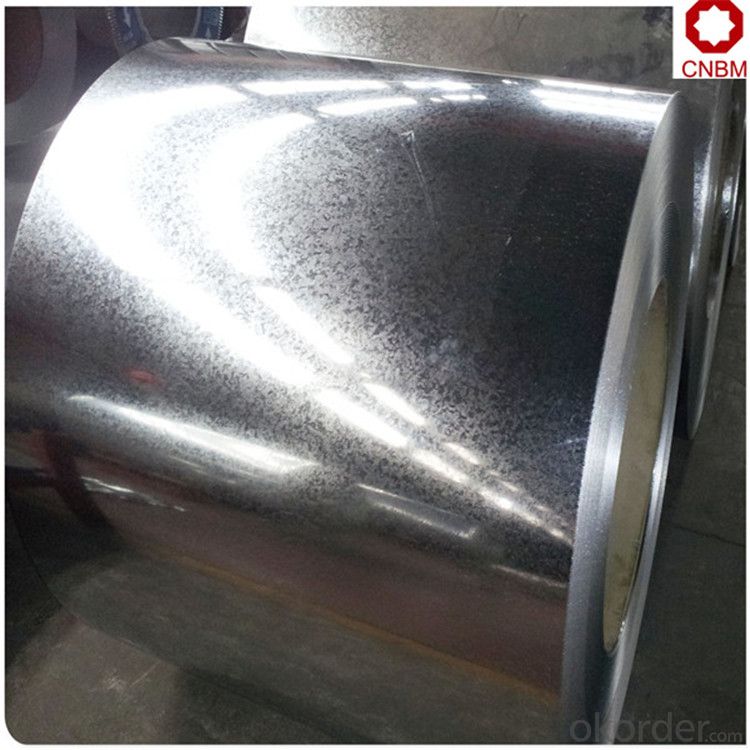

Galvanized steel strip coil in SGCC hot-dipped

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 32634 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Standard and Grade :

Hot-dip galvanized steel coils | ||||

ASTM A653M-06a | EN10327:2004/ 10326:2004 | JISG 3302-2010 | AS-NZS 4534-2006 | |

Commercial quality | CS | DX51D+Z | SGCC | G1+Z |

Structure steel | SS GRADE 230 | S220GD+Z | SGC340 | G250+Z |

SS GRADE 255 | S250GD+Z | SGC400 | G330+Z | |

SS GRADE 275 | S280GD+Z | SGC440 | G350+Z | |

SS GRADE 340 | S320GD+Z | SGC490 | G450+Z | |

SS GRADE550 | S350GD+Z | SGC570 | G550+Z | |

S550GD+Z | G550+Z | |||

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

Company Information

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

- Q: What are the common coil transportation methods?

- The common coil transportation methods include trucking, railway transportation, and shipping.

- Q: This question is directed to anyone who has played or know someone who plays a lap or pedal steel guitar.I've been a guitarist for about 8 years now and have played a variety of styles from rock, fingerstyle/classical, singer/songwriter acoustic stuff, ect, and now I've really had an interest in learning how to play a lap steel or pedal steel guitar. I am completely new to the instrument(s), so I'm seeking all the information I can. I do know that a pedal steel is a lot more expensive, so I'm probably looking to start on a lap steel for now. Basically how should I get started? Should I find a cheap lap steel at a pawn shop or purchase something new? Are there any good method books out there? I'm a pretty experienced guitarist, so should I expect to get the hang of it quickly? Is there much of a market for a lap/pedal steel player? haha.Also, I am left handed. How much trouble would it be to re-string a steel guitar? Or would I be better off getting a left-handed model?

- Hello okorder / I'm not familiar with the brand...it's certainly not commonly played....but it has the features you need for a starter guitar.

- Q: hello guys. im totally new to this metalwork things. i need to do it for my project. i need to join stainless steel wires to build some kind of structure (eiffel tow. for example).i already have the wire and the torch. now the question is: where do i get silver solder? is it expensive? and what is flux for? is it necessary? what does it do? is it expensive?thank u for ur time guys! :)

- the flux you need is powdered borax

- Q: What are the different methods of stretch leveling steel coils?

- There are several methods of stretch leveling steel coils, each with its own advantages and applications. 1. Roller Leveling: This method involves passing the steel coil through a series of rollers that apply pressure to stretch and flatten the material. It is a widely used method for leveling steel coils and offers good control over the leveling process. Roller leveling is suitable for thin and medium gauge steel coils. 2. Tension Leveling: In this method, the steel coil is subjected to high tension forces applied by a set of bridle rolls. The tension helps to elongate and flatten the material, resulting in a level and stress-free coil. Tension leveling is particularly effective for thicker and harder steel coils. 3. Laser Leveling: Laser technology is employed in this method to measure and correct any imperfections in the steel coil. A laser scanner scans the surface of the coil and detects variations, which are then adjusted by a laser beam. Laser leveling offers high precision and is suitable for leveling sensitive and high-value steel coils. 4. Stretcher Leveling: This method involves stretching the steel coil beyond its yield point, which causes the material to permanently deform and eliminate any residual stresses. Stretcher leveling is commonly used for heavy gauge coils and can achieve significant flatness improvements. 5. Tensionless Leveling: As the name suggests, tensionless leveling is performed without applying tension to the steel coil. Instead, hydraulic or pneumatic pressure is used to stretch and flatten the material. This method is suitable for delicate or sensitive steel coils that may be prone to damage under high tension forces. Each method of stretch leveling steel coils has its own advantages, such as control, precision, or suitability for specific types of steel coils. The choice of method depends on factors like the thickness, hardness, and quality requirements of the steel coil, as well as the desired flatness and surface finish.

- Q: How are steel coils inspected for paint adhesion?

- Various methods and techniques are utilized to inspect the adhesion of paint on steel coils. One commonly employed method is the tape test, which involves pressing adhesive tape onto the painted surface and swiftly removing it. The amount of paint that is lifted off by the tape is then examined to assess the adhesion. If the paint adheres well to the steel, only a minimal amount of paint will be removed. Another method employed is the crosshatch adhesion test. This test entails making parallel cuts on the painted surface using a sharp blade, creating a crosshatch pattern. A piece of adhesive tape is then applied over the cuts and rapidly pulled off. The evaluation of the paint that is removed from the crosshatched area determines the adhesion. Furthermore, a visual inspection is frequently conducted to evaluate the overall appearance and adhesion of the paint. Inspectors search for any indications of cracking, peeling, or bubbling, which may indicate poor adhesion. They also check for any areas where the paint may have chipped or flaked off. Moreover, various laboratory tests can be conducted to assess the paint adhesion on steel coils. These tests may include techniques like the pull-off test, where a specialized device is used to measure the force required to remove a small section of the paint from the surface. Other tests may involve subjecting the painted surface to extreme temperature or humidity conditions to assess the paint's performance under different environmental factors. In summary, a combination of visual inspections, tape tests, crosshatch adhesion tests, and laboratory tests are employed to thoroughly inspect steel coils for paint adhesion. These tests ensure that the paint adheres effectively to the steel surface, resulting in a durable and long-lasting finish.

- Q: Aluminum alloy rolling doors and color steel shutter door that good

- The material and structure design Aluminum Alloy rolling shutter door out of the ordinary, can effectively prevent glare and ultraviolet radiation, sunlight greenhouse effect on indoor has completely solved, applicable to all kinds of changes in climate and weather, has a long-term protective effect on indoor environment, tests show that the shutter doors and windows to keep out sunshine rate to 100%, the the rate can reach more than 95% block temperature.

- Q: What are the potential dangers of handling steel coils?

- There are several potential dangers associated with handling steel coils. Firstly, steel coils are heavy and can pose a risk of physical injury if not handled properly. The weight of the coils can cause strains, sprains, or even more serious injuries if dropped or mishandled. This is particularly true when using manual lifting equipment or when attempting to move the coils without proper training or assistance. Secondly, steel coils often have sharp edges or protruding parts that can cause cuts or puncture wounds if not handled with care. These sharp edges can be especially hazardous when attempting to manipulate or position the coils during transportation or storage. It is important to wear appropriate personal protective equipment, such as gloves, to minimize the risk of injury. In addition, steel coils can become unstable if not adequately secured or balanced. Improper stacking or storage of the coils can lead to them shifting or falling, potentially causing serious injuries or damage. It is crucial to follow proper stacking and storage procedures, including using appropriate equipment and supports, to ensure stability and prevent accidents. Furthermore, steel coils are often stored in areas with limited space or uneven surfaces, increasing the risk of trips, falls, or collisions. It is essential to maintain clear and well-organized storage areas, free of obstacles or hazards, to reduce the likelihood of accidents. Lastly, steel coils can be subject to corrosion or rust, which can weaken the metal and compromise their structural integrity. This can increase the risk of the coils collapsing or breaking during handling, potentially causing injuries or damage to property. Regular inspections and maintenance of the coils, as well as proper storage in dry and well-ventilated areas, can help mitigate this risk. Overall, the potential dangers of handling steel coils include physical injuries from their weight and sharp edges, instability during transportation or storage, accidents due to limited space or uneven surfaces, and the risk of structural failure due to corrosion or rust. It is crucial to follow proper safety protocols, receive appropriate training, and use the necessary equipment to minimize these risks and ensure safe handling of steel coils.

- Q: How are steel coils used in the production of roofing panels?

- Steel coils are used in the production of roofing panels by being fed through a machine that shapes and cuts the steel into the desired panel size and shape. The coils are unrolled and flattened, then passed through a series of rollers to form the corrugated or flat panel profile. This process ensures the panels have the strength and durability required for roofing applications.

- Q: What are the guidelines for handling damaged steel coils?

- The guidelines for handling damaged steel coils typically involve inspecting the damage, assessing its severity, and determining if the coil is still safe to handle. If the damage is minor, it may be possible to repair or reinforce the coil. However, if the damage is extensive or compromises the structural integrity of the coil, it is recommended to contact a professional for further evaluation and potential disposal. Additionally, following proper safety protocols, such as wearing protective gear and using equipment suitable for handling heavy loads, is crucial when dealing with damaged steel coils.

- Q: I am making a permanent magnet, just for fun. I am trying to find the best grade of steel to do so with.

- This page on spark test tells how to use a grinding wheel to get a rough idea of what you've got. Includes drawings of sparks for magnet steel;

Send your message to us

Galvanized steel strip coil in SGCC hot-dipped

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 32634 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords