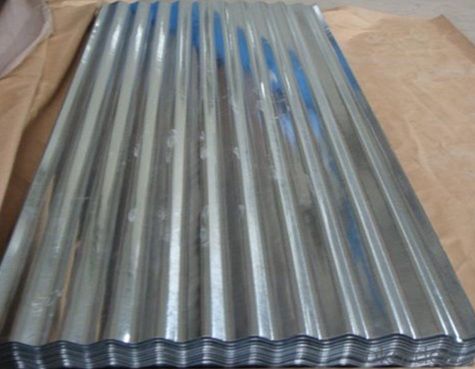

Hot-Dipped Corrugated Steel Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

Hot-Dipped Corrugated Steel Roofing Sheet

--- Corrosion resistance: Pre-coated steel offers excellent corrosion resistance achived through continuous hot DIP galvanization and corrosion resistant primer/polyester coating. Protection is achieved when zinc and steel are together in the presence of moisture; The zinc protects the steel by galvanic action

Product Features

. Traditional aesthetics outlook

. Suitable for new house or renovation.

. Less joints, watertight

. Long life service

. Tedun also provide relative ridge cap, fasteners and other accessories

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

How long will we receive the goods ?

45days after receiving workable L/C

how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q: What are the different surface embrittlement prevention techniques for steel strips?

- Some of the different surface embrittlement prevention techniques for steel strips include: 1. Heat treatment: Proper heat treatment processes such as annealing or tempering can eliminate or reduce embrittlement by relieving internal stresses and improving the steel's microstructure. 2. Coating: Applying protective coatings like zinc or other corrosion-resistant materials can prevent surface embrittlement by shielding the steel from environmental factors that may cause embrittlement. 3. Surface cleaning and preparation: Thoroughly cleaning and preparing the steel surface before any subsequent processes can help remove contaminants or impurities that may contribute to embrittlement. 4. Stress relief: Performing stress relief processes such as shot peening or stress relieving annealing can release internal stresses in the steel, reducing the risk of embrittlement. 5. Alloying: Adding specific alloying elements to the steel composition can enhance its resistance to embrittlement, making it less susceptible to cracking or failure. Overall, a combination of these techniques can be employed to prevent surface embrittlement and ensure the durability and reliability of steel strips.

- Q: Can steel strips be used in the construction of storage tanks?

- Yes, steel strips can be used in the construction of storage tanks. Steel is a commonly used material in tank construction due to its high strength, durability, and ability to withstand extreme temperatures and pressures. Steel strips can be formed, welded, and reinforced to create the necessary shape and structure for storage tanks, making them a reliable choice for such applications.

- Q: What are the different surface corrosion protection methods for steel strips?

- There are several surface corrosion protection methods for steel strips. Some of the common methods include hot-dip galvanizing, electroplating, painting or powder coating, and applying corrosion-resistant coatings such as zinc or nickel. These methods provide a barrier against moisture and corrosive elements, preventing the steel from oxidizing and corroding.

- Q: How are steel strips processed for improved surface finish?

- Steel strips can be processed in various ways to achieve an improved surface finish. One common method is through the process of pickling and oiling. Pickling involves the immersion of steel strips in an acidic bath, such as hydrochloric acid, to remove any scales or impurities on the surface. This helps to create a clean and smooth surface. After pickling, the strips are rinsed and then coated with oil to prevent oxidation and improve the appearance of the surface. Another method used for improving the surface finish of steel strips is cold rolling. This involves passing the strips through a series of rollers at room temperature, which not only reduces the thickness but also enhances the surface finish. Cold rolling helps to create a more uniform and smooth surface, minimizing any imperfections or roughness. Furthermore, steel strips can undergo annealing to improve the surface finish. Annealing is a heat treatment process that involves heating the steel strips to a specific temperature and then slowly cooling them. This process helps to relieve internal stresses and improve the crystal structure of the steel, resulting in a refined and smoother surface. Additionally, steel strips can be subjected to various mechanical treatments, such as grinding or polishing, to further enhance the surface finish. Grinding involves the use of abrasive wheels or belts to remove any imperfections or roughness on the surface. Polishing, on the other hand, utilizes a fine abrasive material to create a smooth and shiny surface. In summary, steel strips can be processed for improved surface finish through methods such as pickling and oiling, cold rolling, annealing, and mechanical treatments like grinding and polishing. These processes help to remove impurities, reduce roughness, and create a clean and smooth surface, resulting in an enhanced appearance and performance of the steel strips.

- Q: What is the impact resistance of a steel strip?

- The impact resistance of a steel strip refers to its ability to withstand sudden forces or impacts without breaking or deforming. Steel is known for its exceptional strength and toughness, which makes it highly resistant to impact. It can absorb and distribute the energy from an impact throughout its structure, preventing cracks or fractures from forming. The impact resistance of a steel strip can vary depending on several factors, such as the grade of steel, the thickness of the strip, and the specific composition of the alloy. Different types of steel, such as stainless steel or carbon steel, may have varying levels of impact resistance. In general, steel strips are designed to have high impact resistance to ensure their durability and longevity in various applications. This makes them suitable for use in industries such as construction, automotive, aerospace, and manufacturing, where they may be subjected to heavy loads, vibrations, or sudden impacts. To determine the impact resistance of a steel strip, various tests, such as Charpy or Izod impact tests, can be conducted. These tests involve striking a notched sample of the steel strip with a pendulum or hammer, measuring the amount of energy absorbed before fracture. Overall, the impact resistance of a steel strip is an important characteristic that contributes to its overall strength and reliability in demanding environments.

- Q: What are the different surface deburring techniques for steel strips?

- There are several surface deburring techniques for steel strips, including manual deburring, mechanical deburring, and chemical deburring. Manual deburring involves using hand tools such as files, sandpaper, or abrasive pads to remove burrs. Mechanical deburring uses machines equipped with brushes, belts, or grinding wheels to achieve the same result. Chemical deburring involves immersing the steel strips in a chemical solution that dissolves the burrs. Each technique has its advantages and is chosen based on the specific requirements and constraints of the project.

- Q: How are steel strips processed for bonding?

- Steel strips are typically processed for bonding by undergoing surface preparation techniques such as cleaning, degreasing, and roughening. This is followed by applying adhesive or bonding agent onto the steel strip, which can be done through various methods like spraying, dipping, or roller coating. The steel strip is then placed in contact with the desired material or substrate, and pressure or heat may be applied to enhance the bonding process.

- Q: What are the factors that affect the surface finish of steel strips?

- Several factors affect the surface finish of steel strips, including the quality of the raw materials used, the type and condition of the equipment used in the manufacturing process, the level of skill and expertise of the operators, the speed and pressure applied during rolling or polishing, the presence of any contaminants or impurities in the environment or on the material itself, and the level of post-processing and finishing applied to the steel strips.

- Q: What are the safety considerations when handling steel strips?

- There are several crucial safety considerations to bear in mind when dealing with steel strips. Firstly, it is essential to wear the proper personal protective equipment (PPE) like gloves and safety glasses to safeguard against cuts and the potential for debris to fly. Moreover, it is important to apply correct lifting techniques to avoid back injuries, as steel strips can be heavy and sharp. Another point to consider is the likelihood of steel strips having sharp edges or burrs. To prevent cuts or punctures, it is imperative to examine the strips for any sharp or jagged edges before handling them. If any defects are detected, the strips should be adequately deburred or filed down to eliminate any hazards. In addition, steel strips can become slippery, particularly if they are coated or have oils on them. Hence, it is crucial to maintain a clean and dry working area to prevent slipping and falling. If necessary, anti-slip mats or suitable footwear should be utilized to enhance traction and stability. Finally, when handling steel strips, it is vital to be mindful of the potential hazards associated with their storage and transportation. To prevent workers from being harmed by falling or rolling strips, they must be stored securely and in an organized manner. Furthermore, during transportation, steel strips should be appropriately secured to prevent any movement or shifting. Overall, the safety considerations pertaining to steel strip handling revolve around the utilization of appropriate PPE, the implementation of proper lifting techniques, the inspection of sharp edges, the maintenance of a clean work environment, and the assurance of secure storage and transportation. By adhering to these safety measures, the risk of injuries and accidents related to steel strip handling can be significantly minimized.

- Q: How do steel strips perform in terms of sound damping?

- Steel strips have limited sound damping properties due to their high stiffness and low internal damping.

Send your message to us

Hot-Dipped Corrugated Steel Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords