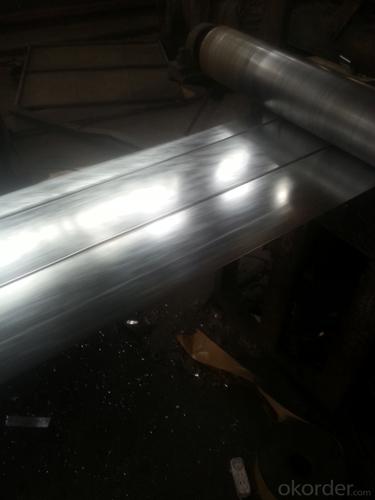

Hot Dip Galvanized Steel Strip

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Galvanized steel strips are widely used in the construction industry, as raw material for the production of corrugated panels, fencing products, drywall panel profiles, ventilation systems etc. Recommended for both outside and inside usage, galvanized steel has a high resistance to corrosion in different environments, due to a protective layer of zinc of 100 –180 grams per square metre.

Hotdip galvanized steel strips are produced by immersing steel in a zinc bath. An appropriate galvanizing process requires a pretreatment process during which the steel passes through different baths which prepare the surface for zinc coating. In this stage, chemicals are used to clean the surface of the steel. After the chemical treatment, the steel coils pass through a bath of melted zinc at temperatures around 460 ° C. The resulting uniform coating is finished through a process of skin-passing to provide smooth and shiny appearance of the finished product. To store for a longer period, the hot-dip galvanized coils can be delivered with a final oil coating, according to the customer’s demand.

Technical specification :

• Steel grade: DX51D+Z• Zinc coverage:30-180 g/sqm on both sides (depending by the requested specification);• Thickness: between 0,2 mm and 1,00 mm;• Width:600mm,914mm,1000mm, 1220mm and 1250 mm;• Coil weight: 4-6 mt;• Coil ID: 508 mm;• Coil OD: 900-1500 mm ;

Depending on their usage, the hot-dip galvanized coil can be delivered slightly oiled.

- Q: What is the thickness range of a steel strip?

- The thickness range of a steel strip can vary depending on the specific application, but it generally ranges from 0.005 inches to 0.5 inches.

- Q: Are steel strips suitable for decorative purposes?

- Steel strips can certainly be used for decorative purposes. They can add a modern and industrial touch to various interior and exterior designs, such as wall panels, furniture accents, or decorative trims. Their sleek and versatile nature allows for both subtle and bold applications, making steel strips a suitable choice for creating aesthetic appeal in different settings.

- Q: How are steel strips processed for riveting?

- Steel strips are processed for riveting through a series of steps to ensure the highest level of quality and efficiency in the riveting process. First, the steel strips are inspected for any defects or imperfections, such as rust, dents, or scratches. Any damaged strips are discarded to prevent any compromises in the final product. Next, the steel strips are cleaned and degreased to remove any dirt, oil, or other contaminants that may be present on the surface. This step is crucial as it ensures proper adhesion and prevents any potential issues during the riveting process. After cleaning, the strips are then cut into the desired lengths using specialized cutting tools or machinery. The cutting process is precise and accurate to ensure consistency in the dimensions of the strips. Once the strips are cut, they may undergo further shaping or bending to match the specific requirements of the riveting application. This can be done through various methods such as rolling, stamping, or using specialized shaping tools. The final step in processing steel strips for riveting involves the insertion of rivet holes. These holes are typically drilled or punched into the strips at specified intervals and locations. The size and shape of the rivet holes are determined by the design requirements and the type of rivet being used. Overall, the processing of steel strips for riveting involves thorough inspection, cleaning, cutting, shaping, and hole insertion to ensure that the strips are ready for the riveting process. By following these steps, manufacturers can produce high-quality steel strips that are suitable for a wide range of riveting applications.

- Q: Can steel strips be used as spring materials?

- Yes, steel strips can be used as spring materials. Steel is a commonly used material for springs due to its high strength, durability, and ability to return to its original shape after being deformed. Steel strips can be manufactured and shaped into various types of springs, such as flat springs, coil springs, or leaf springs, depending on the specific application and design requirements. The hardness and thickness of the steel strip can be adjusted to achieve the desired spring characteristics, such as spring rate, load capacity, and deflection. Moreover, steel strips can also be heat-treated or coated to further enhance their mechanical properties and resistance to corrosion.

- Q: How are steel strips tested for chemical composition?

- The chemical composition of steel strips can be assessed through the utilization of a technique known as spectroscopy. Spectroscopy involves the examination of the steel's elemental composition by measuring the wavelengths of light emitted or absorbed by the elements within the steel. Multiple methods of spectroscopy are employed in the testing of steel strips, including X-ray fluorescence (XRF) spectroscopy and optical emission spectroscopy (OES). XRF spectroscopy entails the irradiation of the steel with X-rays, which prompts the steel's atoms to emit distinctive X-ray fluorescence. By analyzing the emitted X-rays, the elemental composition of the steel can be ascertained. Conversely, OES involves heating the steel to high temperatures, which leads to the emission of light at specific wavelengths by the atoms. Through the analysis of this emitted light, the elemental composition of the steel can be determined. OES is frequently employed in the analysis of low-alloy steels and stainless steels. Apart from spectroscopy, other techniques such as mass spectrometry and inductively coupled plasma (ICP) analysis can also be employed in the assessment of the chemical composition of steel strips. These techniques involve the ionization of the atoms within the steel and the subsequent measurement of the mass-to-charge ratios of the resulting ions. By comparing these ratios to established standards, the elemental composition of the steel can be identified. In conclusion, the chemical composition of steel strips can be assessed through the utilization of a range of spectroscopic and analytical techniques, which offer precise and dependable results. These tests play a crucial role in guaranteeing the quality and performance of steel products across various industries.

- Q: How are steel strips used in the production of medical implants?

- Steel strips are used in the production of medical implants as a raw material that can be shaped, cut, and formed into precise components such as screws, plates, or rods. The steel strips provide the necessary strength, durability, and biocompatibility required for these implants, ensuring their long-term stability and functionality within the human body.

- Q: How are steel strips processed for sealing?

- Steel strips are processed for sealing through a series of steps which typically include cleaning, coating, and forming. First, the steel strips are thoroughly cleaned to remove any dirt, oil, or other contaminants that may interfere with the sealing process. Then, a coating is applied to the strips, often through methods like galvanizing or electroplating, to provide protection against corrosion and improve their sealing properties. Finally, the strips are formed into the desired shape, such as a gasket or a seal, using techniques like roll forming or stamping, ensuring they meet the specific requirements of the sealing application.

- Q: How are steel strips processed for surface plating?

- To ensure proper adhesion and a smooth finish, the surface plating of steel strips involves a series of steps. These steps typically include: 1. Thoroughly cleaning the steel strips to eliminate any surface contaminants like dirt, grease, or other substances. This is accomplished by employing a combination of chemical cleaning agents and mechanical scrubbing. 2. Treating the cleaned steel strips to prepare their surface for plating. This can involve various techniques such as pickling, acid etching, or mechanical roughening. The objective is to create a roughened surface that promotes better adhesion of the plating material. 3. Immersing the prepared steel strips in an electrolyte bath containing the desired plating material. An electric current is then applied to the bath, causing the plating material to adhere to the steel strips. The plating material can be zinc, nickel, chromium, cadmium, or other metals depending on the desired properties and appearance. 4. Subjecting the electroplated steel strips to additional treatments to enhance the properties of the plating. These treatments may include heat treatment, passivation, or the application of a protective coating. These steps contribute to improving the plating's durability, corrosion resistance, and aesthetic appearance. 5. Implementing quality control measures throughout the entire process to ensure the plating meets the required specifications. Visual inspection, thickness measurement, adhesion tests, and other testing methods are employed to guarantee high-quality plating that meets the desired standards. By following these steps, steel strips can undergo effective surface plating, resulting in enhanced durability, corrosion resistance, and an appealing finish.

- Q: What are the dimensional tolerances for steel strips?

- The dimensional tolerances for steel strips depend on various factors such as the specific grade of steel, the manufacturing process, and the intended application. However, common dimensional tolerances for steel strips typically range from +/- 0.005 inches to +/- 0.030 inches, depending on the thickness and width of the strip. It is always advisable to consult the manufacturer or relevant industry standards for precise dimensional tolerances based on specific requirements.

- Q: What are the common applications of steel strips?

- Steel strips have various common applications across industries. They are extensively used in manufacturing automotive parts, such as body panels, brackets, and reinforcements. Steel strips also find their use in the construction sector for producing roofing, cladding, and framing materials. Additionally, they are utilized in the production of electrical appliances, household goods, and various industrial machinery components. The versatility, durability, and strength of steel strips make them a preferred choice for a wide range of applications.

Send your message to us

Hot Dip Galvanized Steel Strip

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords