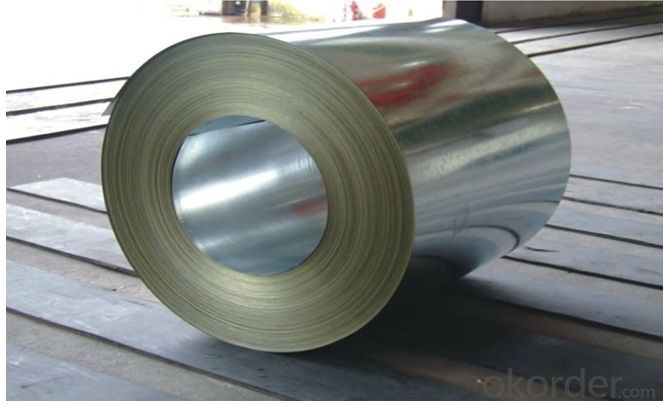

Steel Coil/Hot Dip Galvanized Steel Strips Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Coil/Hot Dip Galvanized Steel Strips Coil Description:

Galvanized steel coil are widely used in the construction industry, as raw material for the production of corrugated panels, fencing products, drywall panel profiles, ventilation systems etc. Recommended for both outside and inside usage, galvanized steel has a high resistance to corrosion in different environments, due to a protective layer of zinc of 100 – 180 grams per square metre.

Main Feature of Steel Coil/Hot Dip Galvanized Steel Strips Coil:

Hot-dip galvanized steel coils are produced by immersing steel in a zinc bath. An appropriate galvanizing process requires a pretreatment process during which the steel passes through different baths which prepare the surface for zinc coating. In this stage, chemicals are used to clean the surface of the steel. After the chemical treatment, the steel coils pass through a bath of melted zinc at temperatures around 460 ° C. The resulting uniform coating is finished through a process of skin-passing to provide smooth and shiny appearance of the finished product. To store for a longer period, the hot-dip galvanized coils can be delivered with a final oil coating, according to the customer’s demand.

Steel Coil/Hot Dip Galvanized Steel Strips Coil Specification:

Steel strips coils galvanized

Material: Q195, Q215, Q235, Q345B, SGCC, DX51D+Z

Thickness:0.75-4.5mm

Width:32-750mm

Zinc coating: 60-550g/m2

Steel Coil/Hot Dip Galvanized Steel Strips Coil Images:

FAQ:

Q: Are you manufacturer of trading company?

A: Yes.

- Q: How do steel strips contribute to product durability in various applications?

- Steel strips contribute to product durability in various applications by providing strength, rigidity, and resistance to wear and corrosion. The high tensile strength of steel allows it to withstand heavy loads and impacts, making it suitable for structural components in buildings, bridges, and machinery. Additionally, the protective coating on steel strips helps prevent rust and corrosion, ensuring the longevity of products in harsh environments. Overall, steel strips enhance the durability and reliability of products across a wide range of industries.

- Q: How are steel strips used in the production of automotive brakes?

- Steel strips are used in the production of automotive brakes as they provide strength and durability to the braking system. These strips are commonly used for manufacturing brake pads, which are crucial components that come into contact with the rotors to slow down or stop the vehicle. The steel strips act as a base material for brake pads, ensuring they can withstand high temperatures and friction generated during braking. Additionally, the strips may be utilized in other brake system parts like shims, springs, or backing plates, contributing to the overall effectiveness and reliability of automotive brakes.

- Q: What are the specifications for steel strips used in the production of springs for firearms?

- The specifications for steel strips used in the production of springs for firearms typically include factors such as specific dimensions, mechanical properties (such as strength and hardness), surface finish requirements, and composition of the steel alloy. These specifications ensure that the steel strips possess the necessary characteristics to withstand the high stress and repetitive motion required for spring operation in firearms.

- Q: How are steel strips used in the manufacturing of pressure vessels?

- Steel strips are used in the manufacturing of pressure vessels to provide strength and durability to the structure. These strips are typically formed into cylindrical or spherical shapes and then welded together to create a vessel capable of withstanding high levels of internal pressure. The steel strips undergo various processes such as rolling, cutting, and shaping to achieve the desired dimensions and specifications required for the pressure vessel.

- Q: What are the future prospects for the steel strip industry?

- The steel strip industry has a promising future ahead. Despite facing challenges in recent years such as overcapacity and trade disputes, there are several factors indicating a positive outlook. To begin with, the global increase in construction and infrastructure development activities is expected to drive the demand for steel strips. These strips are extensively used in various construction applications like roofing, flooring, and cladding. As countries continue to invest in infrastructure building and modernization, the demand for steel strips is likely to rise. Furthermore, the automotive industry, a major consumer of steel strips, is undergoing a transformation with the emergence of electric vehicles and autonomous driving technologies. This shift necessitates the production of lightweight and high-strength materials, including steel strips, to meet the changing needs of the industry. Consequently, the steel strip industry is expected to benefit from the demand for advanced materials in the automotive sector. Additionally, the increasing emphasis on sustainable and eco-friendly practices is expected to drive the adoption of steel strips. Steel is a recyclable material that can contribute to reducing carbon emissions and achieving sustainability goals. This trend is likely to fuel the demand for steel strips as companies and governments prioritize environmental responsibility. Moreover, advancements in technology and manufacturing processes are expected to enhance the efficiency and quality of steel strip production. This will result in cost reductions and increased productivity, making steel strips more competitive in the market. However, it is crucial to acknowledge that the steel strip industry will still face challenges. Fluctuations in raw material prices, trade barriers, and competition from alternative materials like aluminum and composites can affect the industry's growth. Additionally, the industry needs to address sustainability concerns and invest in research and development to innovate and meet the evolving demands of various sectors. In conclusion, the future prospects for the steel strip industry are positive. With the increasing demand from the construction and automotive sectors, the growing focus on sustainability, and advancements in technology, the industry is well-positioned for growth. However, it must adapt to changing market dynamics and invest in innovation to remain competitive in the global marketplace.

- Q: What are the different grades of steel strips?

- There are various grades of steel strips, including low carbon, medium carbon, high carbon, and alloy steel strips. These grades differ in their carbon content, which affects their strength, hardness, and ability to be formed or welded.

- Q: Can steel strips be used in the medical industry?

- Indeed, the medical industry has found great use for steel strips. These versatile strips have a multitude of applications within the field. Surgical instruments, medical implants, and medical equipment are just a few examples of the many uses for steel strips. The exceptional qualities of steel strips, such as strength, durability, and resistance to corrosion, make them ideal for applications requiring precision and reliability. They can be easily molded and shaped into various medical devices, ensuring that they meet the specific needs of both patients and healthcare professionals. In addition, steel strips can be treated on their surface to enhance their biocompatibility, rendering them suitable for use in implantable medical devices. The surface treatment offers added benefits, such as reducing the risk of infections and promoting better integration with the patient's body. Furthermore, steel strips possess excellent mechanical properties, allowing for precise machining and fabrication. They can be easily sterilized and cleaned, making them perfect for use in sterile environments. It is worth noting that stainless steel is commonly employed in the medical industry due to its resistance to corrosion and ability to withstand harsh sterilization processes. However, other types of steel can be used depending on the specific requirements of the medical application. In conclusion, the medical industry has embraced the use of steel strips due to their many advantageous properties. Their strength, durability, corrosion resistance, and compatibility with surface treatments make them a dependable choice for manufacturing surgical instruments, medical implants, and other medical equipment.

- Q: What are the different methods of heat treatment for steel strips?

- Some of the different methods of heat treatment for steel strips include annealing, quenching, tempering, and normalizing.

- Q: How are steel strips formed into different shapes?

- Steel strips can be formed into different shapes through various processes such as bending, rolling, stamping, or pressing. These techniques apply pressure or force to manipulate the steel strip into the desired shape, allowing for the creation of a wide range of forms and structures.

- Q: What are the main factors affecting the heat treatment of steel strips?

- The main factors affecting the heat treatment of steel strips include the initial composition of the steel, the heating and cooling rates, the temperature and time of the heat treatment process, the presence of impurities or alloying elements, and the desired properties of the final product.

Send your message to us

Steel Coil/Hot Dip Galvanized Steel Strips Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords