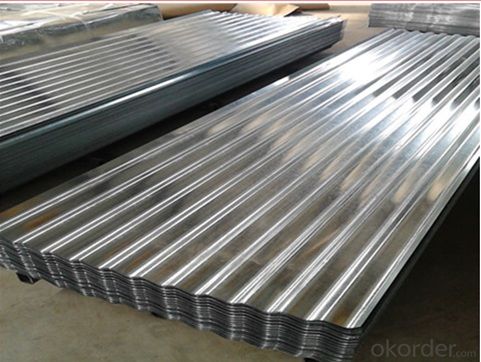

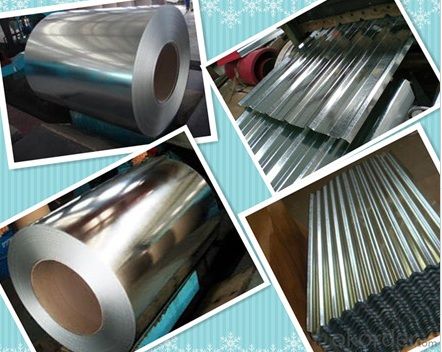

Hot-Dipped Corrugated Steel Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

Hot-Dipped Corrugated Metal Roofing Sheet

--- Corrosion resistance: Pre-coated steel offers excellent corrosion resistance achived through continuous hot DIP galvanization and corrosion resistant primer/polyester coating. Protection is achieved when zinc and steel are together in the presence of moisture; The zinc protects the steel by galvanic action

Product Features

. Traditional aesthetics outlook

. Suitable for new house or renovation.

. Less joints, watertight

. Long life service

. Tedun also provide relative ridge cap, fasteners and other accessories

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

How long will we receive the goods ?

45days after receiving workable L/C

how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q: What is the thickness range for steel strips?

- The thickness range for steel strips can vary depending on the specific application and type of steel, but generally, it can range from very thin strips measuring around 0.1mm to thicker strips measuring up to 6mm or even more.

- Q: What are the weight considerations for steel strips?

- The weight considerations for steel strips primarily depend on the desired application. Factors such as the thickness, width, and length of the strip, as well as the type and grade of steel used, can significantly impact its weight. Additionally, the weight of steel strips is crucial for transportation and handling purposes, as it affects the ease of movement, storage, and installation.

- Q: Are steel strips suitable for the manufacturing of architectural structures?

- Yes, steel strips are suitable for the manufacturing of architectural structures. Steel strips possess high strength and durability, making them ideal for constructing various architectural elements such as beams, columns, and frames. Their versatility allows for flexibility in design and enables the creation of both simple and complex structures. Additionally, steel strips offer resistance to corrosion and fire, ensuring the longevity and safety of the architectural structures.

- Q: What are the main quality standards for steel strips?

- The main quality standards for steel strips include dimensions, surface quality, mechanical properties, and chemical composition. These standards ensure that steel strips meet the required specifications for their intended applications and ensure consistency and reliability in their performance.

- Q: How are steel strips protected against fire?

- Steel strips are often protected against fire by applying fire-resistant coatings or by surrounding them with fireproof insulation materials. This helps to prevent the steel from reaching critical temperatures that could weaken its structural integrity during a fire. Additionally, fire suppression systems such as sprinklers or fire extinguishers may be installed in the vicinity to quickly extinguish any potential fire and minimize damage.

- Q: How do steel strips perform in terms of creep resistance?

- Steel strips generally have good creep resistance due to their high strength and stiffness. The low carbon content in steel helps in minimizing the creep deformation at high temperatures and under prolonged stress. Additionally, the microstructure and composition of the steel can also be modified to enhance its creep resistance. Overall, steel strips are known for their favorable performance in terms of creep resistance.

- Q: What are the cutting options available for steel strips?

- Depending on the specific requirements and desired outcome, there are several cutting options available for steel strips. One common method is shearing, which involves using a shearing machine with two blades to slice through the material. Shearing is ideal for straight cuts and can be used for both thin and thick steel strips. Another option is laser cutting, which uses a laser beam to melt and vaporize the steel strip. This method is precise and efficient, making it perfect for intricate and complex designs. However, it may not be suitable for very thick steel strips. Waterjet cutting is a versatile method that utilizes a high-pressure stream of water mixed with an abrasive material. It can handle various thicknesses of steel and is ideal for cutting heat-sensitive materials or those with a high melting point. Plasma cutting, on the other hand, involves ionizing gas and an electric arc to cut through the steel strip. It is effective for both ferrous and non-ferrous metals and can handle different thicknesses. Plasma cutting is known for its speed and ability to cut through thicker materials. Lastly, saw cutting uses a circular saw blade or bandsaw to cut through the steel strip. It is suitable for straight cuts and commonly used for thicker steel strips or when precise shapes are not required. When selecting a cutting method for steel strips, it is crucial to consider factors such as desired precision, speed, complexity of the design, and material thickness. Each cutting option has its advantages and limitations, so it is important to choose the most appropriate method based on the specific needs of the project.

- Q: What are the different grades of steel used for making strips?

- The different grades of steel used for making strips can vary depending on the specific application and requirements. Some common grades include low carbon steel, high carbon steel, stainless steel, and alloy steel. Each grade has its own unique properties, such as strength, corrosion resistance, and formability, which make them suitable for different industrial purposes.

- Q: How are steel strips formed into different shapes?

- Steel strips are formed into different shapes through a process called steel strip forming. This process involves several steps to manipulate the steel strips into desired shapes. Firstly, the steel strips are uncoiled from a large steel coil and fed into a forming machine. This machine uses a series of rollers, dies, and press brakes to shape the steel strips. The rollers apply pressure to the strips, gradually bending and curving them into the desired shape. The dies and press brakes are used to further shape the steel strips by applying precise amounts of force at specific points. This allows for the creation of more complex shapes and angles. In some cases, heat may be applied to the steel strips during the forming process to make them more malleable and easier to shape. This is particularly common when forming steel strips into intricate or tight shapes. Once the desired shape has been achieved, the steel strips are cooled and cut to the required length. They are then ready for further processing or use in various industries, such as automotive, construction, or manufacturing. Overall, the process of forming steel strips into different shapes involves a combination of mechanical force, heat, and precision engineering techniques to create the desired end product.

- Q: How do steel strips contribute to weight reduction in various applications?

- Steel strips contribute to weight reduction in various applications by being lightweight yet strong. They provide a high strength-to-weight ratio, allowing manufacturers to use thinner and lighter steel strips without sacrificing structural integrity or performance. This reduction in weight can lead to improved fuel efficiency in transportation, increased payload capacity in aerospace, and overall cost savings in various industries.

Send your message to us

Hot-Dipped Corrugated Steel Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords