Hot-dip Aluzinc Steel Building Roof Walls 615-009-01

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 66 kg/m²

- Supply Capability:

- 11 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

. Description of the Hot-dip Aluzinc Steel:

Hot-dip aluzinc steel structure is composed of aluminum-zinc alloy, consisting of 55% aluminum, 43% zinc and 2% at 600 ℃ silicon solidification temperature and composition, the entire structure is made of aluminum - iron - silicon - zinc, to form a dense quaternary crystals an alloy.

Hot-dip aluzinc steel has many excellent features: strong corrosion resistance, is three times the pure galvanized sheet; zinc surface with beautiful flowers, can be used as a building outside board.

Applications of hot-dip aluzinc steel:

1)Building: roof, walls, garages, soundproof walls, pipes and modular housing.

2)Automotive: muffler, exhaust pipes, wiper accessories, fuel tank, truck boxes, etc.

3)Appliances: refrigerator back, gas stove, air conditioners, microwave oven, LCD frame, 4)CRT-proof band, LED backlight, electrical cabinets, etc.

5)Farm: barn, sheds, silos, piping and other greenhouse.

6)Other: breaking heat insulation cover, heat exchangers, dryers, warm water, etc.

Although steel had been produced in bloomery furnaces for thousands of years, steel's use expanded extensively after more efficient production methods were devised in the 17th century for blister steel and then crucible steel. With the invention .

2.Main Features of the Hot-dip Aluzinc Steel:

• Excellent corrosion resistance

• High temperature oxidation resistance

• High hot reflectance

• Good manufacturability

•Beautiful appearance

•Surface coating

•Cost-effective

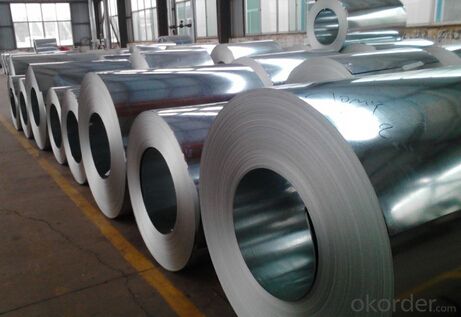

3.Hot-dip Aluzinc Steel Images

4.Hot-dip Aluzinc Steel Specification

AVAILABLE SPECIFICATION

HOT-DIP ALUZINC STEEL COILS | |

THICKNESS | 0.16mm-3.5mm |

WIDTH | 1250mm MAX |

COATING MASS | |

SPANGLE | Regular Spangle, Minimized Spangle, Zero Spangle |

SURFACE TREATMENT | Chromated / non-chromated, Oiled / non-oiled, Anti Finger Print |

COIL INNER DIAMETER | 508mm or 610mm |

5.FAQ of Hot-dip Aluzinc Steel

We have organized several common questions for our clients,may help you sincerely:

1.What advantages does your company have?

Cement : Annual capacity of 400 million tons, No. 1 in the world

Fiberglass: Annual capacity of 1 million tons fiberglass, No. 1 in the world.

2.What advantages do your products have?

Firstly, our base material is of high quality, Their performance is in smooth and flat surface,no edge wave ,good flexibility.

Secondly, high quality zinc ingoats, 97.5% zinc,1.5% silicon,1% others, the same zinc coating measured by metal coating thickness or by zinc weight

Thirdly, high precision: Tolerance strictly according to ASTM or JISG standard even more rigid.

We have full stes of testing equipment(for t best, cupule,chromatism,salt spray resistance, etc) and professional engineers.

3.Could you let me approach about your company in Dubai?

Located at Jebel Ali Free Zone in Dubai, CNBM Dubai Logistics Complex is adjacent to -Jebel Ali sea port-the largest port in UAE and Al Maktoum Airport-

- Q: How are steel strips used in the production of springs?

- Due to their high strength and flexibility, steel strips are widely utilized in spring manufacturing. These strips are typically composed of carbon steel, which boasts exceptional tensile strength and the ability to endure repeated bending and stretching without breaking or deforming. To produce springs, the steel strips undergo initial cutting to achieve the desired dimensions. Subsequently, they are coiled or wound around a mandrel, shaping the spring's basic form. The coiling process entails precise control over the strip's tension and curvature, thus attaining the desired characteristics of the spring, such as stiffness and compression or extension properties. Following the coiling stage, the steel strip is often heat-treated to enhance its mechanical properties. This involves subjecting the strip to high temperatures and swiftly cooling it, a technique known as quenching. Heat treatment serves to elevate the steel's strength and hardness, thereby rendering it more resilient and durable. Once the heat treatment is finalized, the spring typically undergoes further processing steps, such as stress relieving or shot peening, to optimize its performance and ensure longevity. Stress relieving eliminates any residual stresses that may have accumulated during the coiling and heat treatment procedures, while shot peening bombards the spring's surface with tiny metal particles to enhance its resistance to fatigue. Overall, steel strips play a pivotal role in spring production by providing the necessary strength and flexibility required for these mechanical components. They are shaped, heat-treated, and processed to create springs with specific properties suitable for a wide array of applications, ranging from automotive and industrial machinery to household appliances and medical devices.

- Q: How are steel strips used in the manufacturing of bearings?

- Due to their strength, durability, and ability to withstand high temperatures, steel strips are commonly employed in the production of bearings. These strips serve as the primary material for the inner and outer rings of the bearing, establishing a stable and rigid framework. To initiate the manufacturing process, high-quality steel strips are meticulously selected and meticulously cut and shaped to form the rings. Often, the strips are subjected to heat treatment, which enhances their mechanical properties, including hardness and toughness, both of which are essential for optimal bearing performance. After the rings take shape, they undergo additional machining processes to achieve the precise dimensions and surface finish required. This guarantees that the bearings fit accurately and operate smoothly within the intended application, thus minimizing friction and maximizing performance. Steel strips also play a crucial role in maintaining the alignment and stability of the bearing components. They provide support for the balls or rollers responsible for the rotational movement of the bearing. By offering a solid surface against which the rolling elements can move, the strips effectively reduce friction, enabling the bearing to operate efficiently. Furthermore, steel strips are often treated with anti-corrosion materials or lubricants to safeguard them against wear, rust, and other environmental factors. This not only extends the lifespan of the bearing but also enhances its overall performance across various applications. In conclusion, steel strips are an indispensable element in the manufacture of bearings. They contribute strength, durability, and stability to the bearing structure, allowing it to withstand heavy loads, resist wear, and operate seamlessly.

- Q: How are steel strips used in the production of oil and gas pipelines?

- The production of oil and gas pipelines heavily relies on steel strips, which play a vital role. These strips, typically constructed from high-quality steel, possess the necessary strength and durability to withstand the harsh conditions of the oil and gas industry. To begin the pipeline production process, steel coils are manufactured. This involves continuously rolling steel sheets into cylindrical shapes, ensuring uniformity and consistency in the resulting steel strips, which is crucial for maintaining the integrity of the pipeline. Once prepared, the steel coils are unwound and fed into a pipe mill. In the mill, the steel strips are shaped into the required form, usually a circular cross-section. This is achieved by bending the strips into a pipe shape and welding the edges together. The welded seam undergoes inspection to verify its strength and integrity. After the formation of the pipes, they undergo various treatments and tests to enhance their durability and reliability. Heat treatments are applied to improve the mechanical properties and corrosion resistance of the steel. Additionally, non-destructive testing methods, such as ultrasonic or radiographic examination, are utilized to identify any defects or weaknesses that may compromise the performance of the pipeline. Following successful transformation into pipes and passing all necessary tests, the steel strips undergo further processing to meet specific requirements. This may involve coating the pipes with protective layers to prevent corrosion or adding insulation to maintain the desired temperature of the transported fluids. Ultimately, the pipes are transported to the construction site, where they are laid and connected to form the extensive network of oil and gas pipelines. The strength and durability of the steel strips ensure the structural integrity of the pipeline, facilitating the safe and efficient transportation of oil and gas over long distances. In conclusion, steel strips are an indispensable component of the oil and gas pipeline production process. They are shaped into pipes, undergo treatments and tests to enhance their durability, and are ultimately laid and connected to form the extensive pipeline network. Without steel strips, the construction and operation of oil and gas pipelines would be severely compromised.

- Q: Can steel strips be used in the oil and gas industry?

- Yes, steel strips can be used in the oil and gas industry. They are commonly used for various applications such as pipelines, storage tanks, and offshore platforms due to their strength, durability, and resistance to corrosion.

- Q: What are the common heat treatment processes for steel strips?

- The common heat treatment processes for steel strips include annealing, quenching, tempering, and hardening. Annealing is a process of heating the steel strip to a specific temperature and then slowly cooling it down to relieve internal stresses and improve its machinability. This process also enhances the ductility and toughness of the steel, making it easier to form and work with. Quenching involves rapidly cooling the steel strip by immersing it in a quenching medium such as oil or water. This rapid cooling hardens the steel, making it stronger and more wear-resistant. However, quenched steel can be brittle, so further tempering is often required. Tempering is a process that follows quenching and involves reheating the steel strip to a specific temperature and then cooling it at a controlled rate. This process reduces the brittleness caused by quenching and improves the toughness and ductility of the steel. Tempering also helps to relieve internal stresses and increase the steel's resistance to fracturing. Hardening is a process that involves heating the steel strip to a high temperature and then rapidly cooling it, similar to quenching. This process increases the hardness and strength of the steel, making it suitable for applications that require high wear resistance and durability. Each of these heat treatment processes can be adjusted in terms of temperature, cooling rate, and duration to achieve specific desired properties in the steel strip. The choice of heat treatment process depends on the intended application and the desired mechanical and physical properties of the steel.

- Q: What are the common defects found in steel strips?

- Some common defects found in steel strips include surface scratches, rust or corrosion, uneven thickness, edge cracks, and waviness.

- Q: How are steel strips heat-treated for specific applications?

- Steel strips are heat-treated for specific applications by subjecting them to controlled heating and cooling processes. This involves heating the steel strips to a specific temperature and holding it there for a predetermined amount of time. The strips are then rapidly cooled, or quenched, to achieve the desired hardness, strength, or other mechanical properties. The heat treatment process can also involve tempering or annealing to further refine the steel's properties. Overall, the goal is to tailor the steel strips' microstructure to meet the specific requirements of the intended application.

- Q: What is the typical corrosion resistance of stainless steel strips?

- The typical corrosion resistance of stainless steel strips is high, as they are designed to resist corrosion and rusting even in harsh environments.

- Q: What are the different surface finishes available for steel strips to enhance aesthetics?

- There are several surface finishes available for steel strips to enhance aesthetics, including polished, brushed, embossed, and patterned finishes. These finishes can give the steel strips a sleek and modern look, or add texture and depth to the surface. Additionally, coatings such as powder coating or electroplating can also be applied to further enhance the appearance and provide additional protection against corrosion.

- Q: How are steel strips used in the manufacturing of consumer goods?

- Steel strips are used in the manufacturing of consumer goods primarily for their strength and versatility. They are commonly utilized in various processes, such as forming, bending, and cutting, to create components or parts for a wide range of products. Steel strips can be found in appliances, automobiles, furniture, construction materials, and many other consumer goods, providing the necessary durability and stability required for these products.

Send your message to us

Hot-dip Aluzinc Steel Building Roof Walls 615-009-01

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 66 kg/m²

- Supply Capability:

- 11 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords