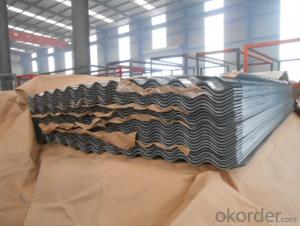

HOT DIPPED GALVANIZED STEEL CORRUGATED SHEETS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GALVANIZED STEEL CORRUGATED SHEETS

THICKNESS:0.14mm

WIDTH:800mm(AFTER CORRUGATION)

LENGTH:3048mm

ZINC COATING:80g/m2

STANDARD:JIS G 3302, SGCH (HARD QUALITY:75HRB-90HRB)

SURFACE:REGULAR SPANGLE, CHROMATED, DRY

PACKAGE WEIGHT:ABOUT 3 TONS

PAYMENT TERM:30% TT advance,70% against BL copy OR 100% LC AT SIGHT.

SHIPMENT: WITHIN 35 DAYS AFTER RECEIVING THE DEPOSIT.

DOUCUMENTS:COMMERCIAL INVOICE IN THREE ORIGINAL,PACKING LIST IN ONE ORIGINAL AND SPECIFICATION,CERTIFICATE OF ORIGIN.

ORIGIN:MADE IN CHINA

LABEL INFORMATION:AS REQUEST.

PORT OF LOADING: XINGANG PORT, CHINA

- Q: What are the different profile options available for steel sheets?

- Steel sheets come in various profile options, each serving distinct purposes and offering unique advantages. Some commonly used profiles are: 1. Plain Sheet: This is the most basic option with a flat surface and no additional features. It is commonly employed for general purposes where aesthetics are not a priority. 2. Corrugated Sheet: These sheets have parallel ridges and grooves, forming a wavy pattern. They provide extra strength and rigidity, making them ideal for roofing, cladding, and fencing. The ridges also facilitate water shedding, preventing water accumulation. 3. Ribbed Sheet: Ribbed sheets have raised parallel ridges or ribs along their length. This profile offers enhanced strength and load-bearing capacity, making it suitable for applications requiring structural integrity, like mezzanine floors, decking, and industrial flooring. 4. Perforated Sheet: Perforated sheets have a pattern of punched holes, allowing for ventilation, light transmission, and drainage. They are commonly used in architectural designs, façades, acoustics, and filtration systems. 5. Tread Plate: Tread plates have an embossed pattern of lines or diamonds on the surface. This profile provides extra grip and slip resistance, making it ideal for industrial flooring, stairs, ramps, and walkways. 6. Expanded Metal: Expanded metal sheets are created by cutting and stretching a flat sheet, resulting in diamond-shaped openings. This profile offers excellent ventilation, visibility, and security, making it suitable for grilles, screens, fences, and enclosures. 7. Lipped Sheet: Lipped steel sheets have an edge or lip bent at a 90-degree angle along one or more sides. This profile provides added strength and stiffness, commonly used for framing, shelving, and edge protection. These are just a few examples of the available profile options for steel sheets. The choice of profile depends on specific requirements such as strength, durability, aesthetics, and functionality.

- Q: What are the different joining methods for steel sheets?

- There are several different joining methods for steel sheets, including welding, bolting, riveting, and adhesive bonding. Welding involves melting the edges of the steel sheets and fusing them together, creating a strong and permanent bond. Bolting involves using screws or bolts to connect the steel sheets, providing a secure and adjustable connection. Riveting involves using rivets to connect the steel sheets by deforming the rivet to create a mechanical bond. Adhesive bonding involves using specialized adhesives to bond the steel sheets together, creating a strong and lightweight connection.

- Q: Can steel sheets be used in marine applications?

- Steel sheets are suitable for marine applications, as they possess high strength and durability. This material is widely chosen due to its ability to endure the challenging conditions of saltwater, as well as its resistance to corrosion. In the construction of ships, offshore platforms, and other marine structures, steel sheets are frequently employed to ensure structural integrity. They can be easily customized to meet specific design requirements. Moreover, to enhance their corrosion resistance in saltwater environments, steel sheets can be coated with protective layers like anti-corrosion paints or galvanization. Overall, steel sheets are a dependable and frequently utilized material across various marine applications.

- Q: What are the different storage methods for steel sheets?

- There are several different storage methods for steel sheets, depending on the specific requirements and space availability. Here are some commonly used storage methods: 1. Flat storage: This is the most basic method where steel sheets are stored horizontally on a flat surface, such as the floor or metal racks. It is suitable for small quantities or when the sheets are not too heavy. 2. Vertical storage: Steel sheets can be stored vertically by placing them against a wall or by using specially designed vertical racks. This method saves floor space and allows for easy access and identification of different sheet sizes. 3. Cantilever racks: These racks have horizontal arms that extend outward from a vertical column, providing support for steel sheets placed on them. Cantilever racks are ideal for storing long and heavy steel sheets, as they allow for easy loading and unloading using forklifts or cranes. 4. Roll-out racks: These racks have rollers or ball bearings that allow steel sheets to be easily rolled in and out, similar to a drawer. Roll-out racks are useful when frequent access to different sheets is required, as they provide good visibility and easy retrieval. 5. A-frame racks: A-frame racks have angled arms that support steel sheets in a slanted position, resembling the letter "A." This method is suitable for storing large quantities of steel sheets and provides easy access while keeping them organized. 6. Automated storage and retrieval systems (AS/RS): These systems use computer-controlled mechanisms to automatically store and retrieve steel sheets. AS/RS can be designed as vertical lift modules or robotic systems, maximizing storage capacity and efficiency. It is important to consider factors such as sheet size, weight, accessibility, and safety when choosing the appropriate storage method for steel sheets. Adequate measures should also be taken to protect the sheets from moisture, dust, and other environmental factors that could potentially affect their quality.

- Q: Can steel sheets be used in corrosive environments like saltwater?

- Steel sheets can be used in corrosive environments like saltwater, but they need to be properly protected through methods such as coating or galvanization to prevent corrosion.

- Q: What are the different types of surface patterns available for steel sheets?

- There are several different types of surface patterns available for steel sheets, including smooth, textured, embossed, diamond, and perforated patterns.

- Q: How are steel sheets protected during storage and handling?

- To safeguard steel sheets and guarantee their quality, a range of methods are employed during storage and handling. A frequently utilized technique involves applying a protective coating or oil to shield the sheets from moisture and other environmental factors that may lead to corrosion or rust. To shield steel sheets from direct sunlight, rain, and adverse weather conditions, they are frequently stored in covered warehouses or designated storage areas. This precautionary measure prevents any potential harm to the sheets and preserves their structural integrity. For transportation and handling, cranes or forklifts equipped with suitable lifting apparatus are commonly used to lift the steel sheets, minimizing the risk of bending or twisting. Moreover, the sheets are meticulously secured and stacked in a manner that reduces the likelihood of damage or deformation. Furthermore, steel sheets are often packaged with materials like plastic or cardboard to provide additional protection against scratches and physical harm. They may also be wrapped or sealed to prevent contact with moisture or contaminants. Overall, the objective is to maintain the quality of steel sheets and prevent any potential damage that could compromise their performance in future applications by ensuring they are stored and handled in a secure and controlled environment.

- Q: Are steel sheets suitable for electrical applications?

- Yes, steel sheets can be suitable for electrical applications. They have good electrical conductivity and can be used for applications such as electrical enclosures, panels, and grounding components. However, it is important to consider factors like insulation and corrosion resistance when using steel sheets in electrical applications.

- Q: Are the steel sheets easy to install?

- Indeed, the installation of steel sheets is generally a straightforward task. Their lightweight nature allows for easier handling and maneuverability throughout the installation procedure. Moreover, steel sheets often come equipped with pre-drilled holes or interlocking systems, which further streamlines the installation process. By employing the correct tools and possessing fundamental construction knowledge, individuals can effortlessly mount steel sheets onto diverse surfaces like roofs, walls, or fences. Nevertheless, it remains crucial to adhere to the manufacturer's instructions and safety guidelines to guarantee a correct and secure installation.

- Q: Can steel sheets be used for containers or storage units?

- Yes, steel sheets can definitely be used for containers or storage units. Steel is a highly durable and strong material that is commonly used in the construction of containers and storage units due to its ability to withstand heavy loads and extreme weather conditions. Steel containers and storage units provide a secure and reliable solution for storing various items such as household goods, tools, equipment, and even larger items like vehicles. Steel sheets used for containers and storage units are often reinforced with additional features such as locking mechanisms, insulation, and ventilation to enhance their functionality. Additionally, steel containers and storage units are also portable and can be easily transported to different locations if needed. Overall, steel sheets are an excellent choice for containers and storage units due to their strength, durability, and versatility.

Send your message to us

HOT DIPPED GALVANIZED STEEL CORRUGATED SHEETS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords